- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

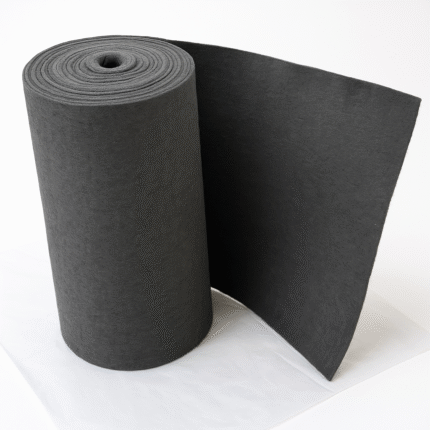

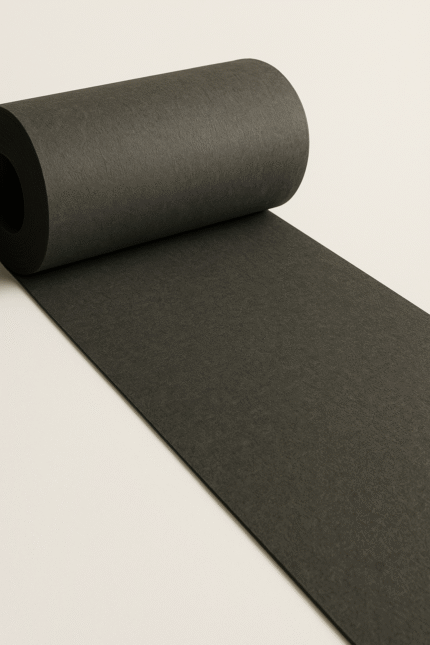

- Carbon Felt / Graphite Felt

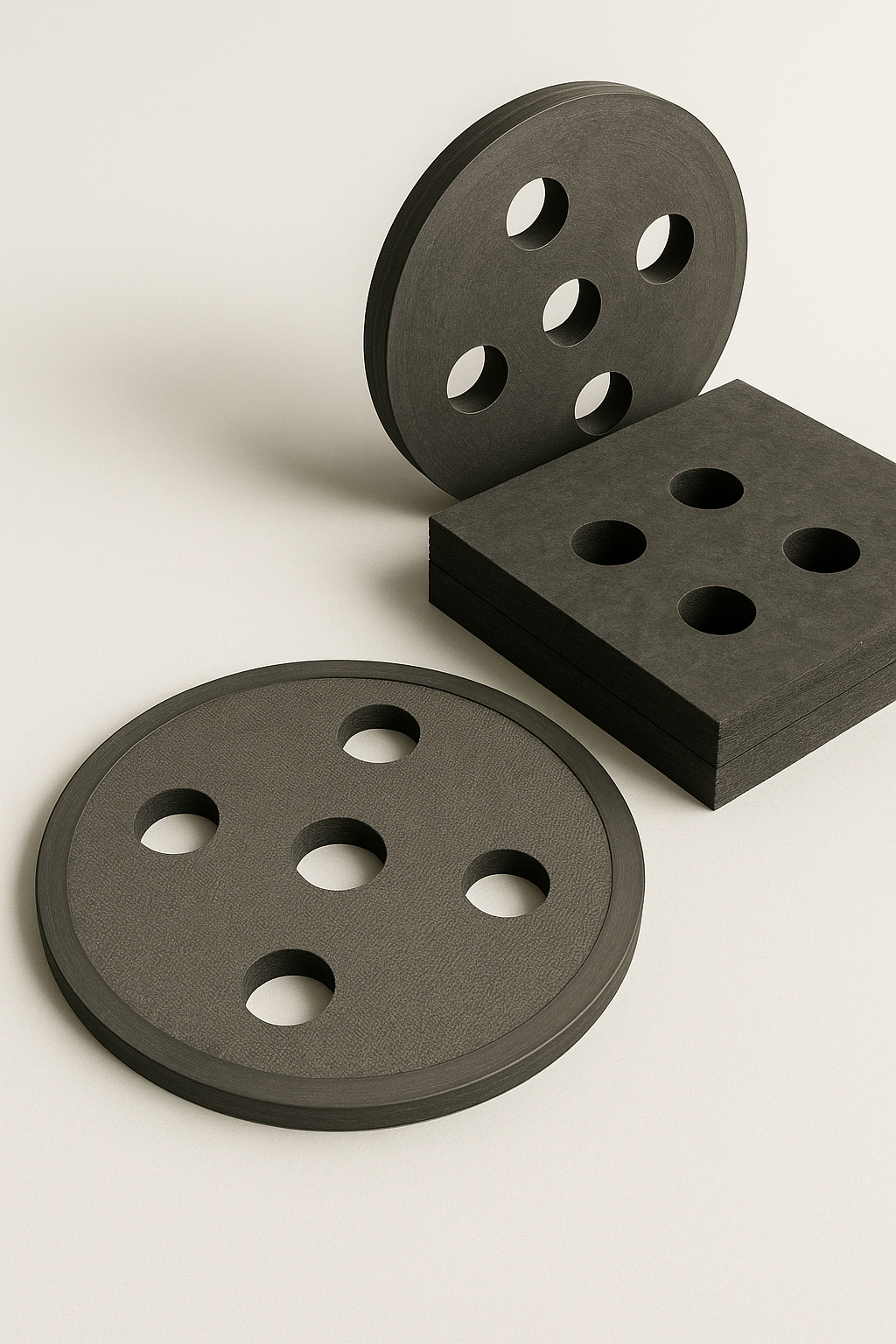

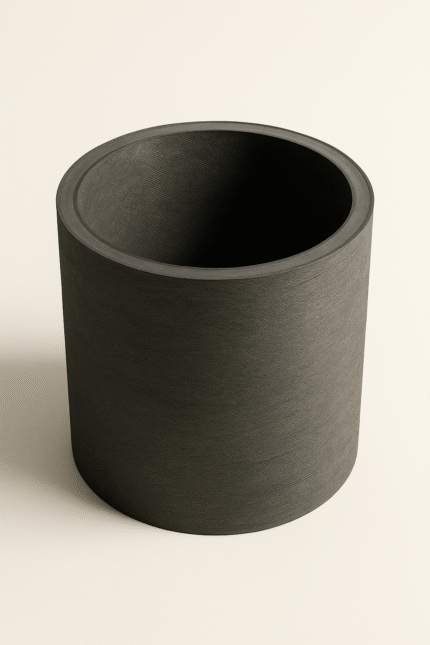

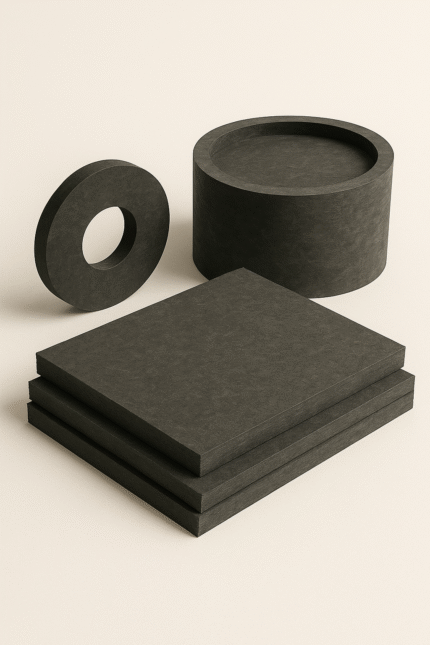

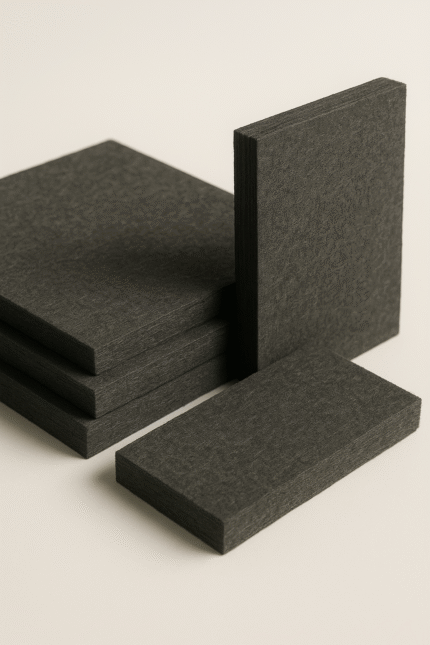

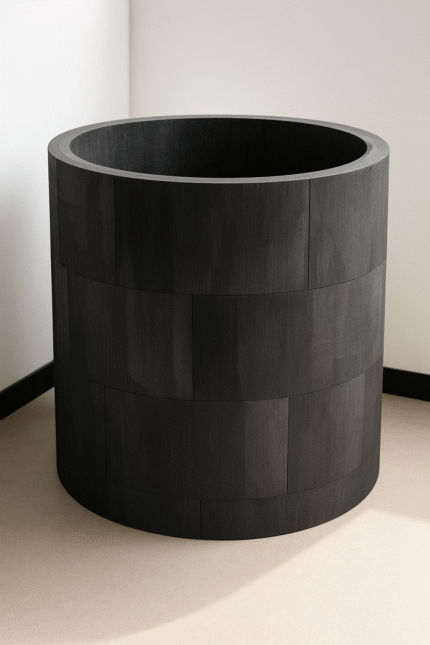

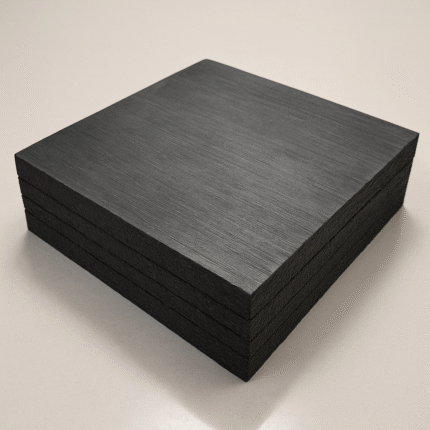

Rigid Graphite Felt Parts

BZNCarbon produces high-quality rigid graphite felt parts engineered for use in extreme thermal, chemical, and mechanical environments. Our parts are manufactured from both PAN-based and Rayon-based rigid graphite felt, available in board, plate, disc, or custom-machined shapes to meet customer-specific technical and dimensional requirements.

We offer optional CFC (Carbon Fiber Composite) or graphite foil surface reinforcement—on one or both sides—based on user needs. Our products are processed at 1800°C, 2200°C, or 2600°C, ensuring superior thermal and mechanical stability.

Category: Carbon Felt / Graphite Felt

Tags: Rigid Graphite Felt Parts, Graphite Felt Parts

Description

Rigid graphite felt parts are developed by high-temperature graphitization of soft felt followed by structural reinforcement into monolithic rigid shapes. These parts offer low thermal conductivity, high carbon purity, and excellent structural integrity at extreme temperatures. They are customizable in both shape and thickness for specialized industrial applications.

Application Areas

Vacuum furnace insulation and heat shields

High-temperature gas or molten metal filtration

Fuel cell porous electrodes

Catalyst supports and chemical-resistant linings

Composite reinforcement for carbon/carbon (C/C) materials

Solar, aerospace, semiconductor, nuclear, and energy storage systems

Technical Specifications – PAN Based Rigid Graphite Felt (BZN-3, 2200°C)

| Property | Value |

|---|---|

| Density | 0.18 g/cm³ |

| Carbon Content | >99.9% |

| Ash Content | ≤200 ppm |

| Flexural Strength | 0.90 MPa |

| Compressive Strength (5% def.) | 0.07 MPa |

| Thermal Conductivity @ 1000°C | 0.32 W/m·K |

| Thermal Conductivity @ 1500°C | 0.44 W/m·K |

| Thermal Conductivity @ 2000°C | 0.59 W/m·K |

| Volatile Content | 0% |

| Electrical Resistivity (Perpendicular) | 900 mΩ·cm |

| Electrical Resistivity (Parallel) | 70 mΩ·cm |

| Max Operating Temp (Vacuum) | 3600°C (6512°F) |

| Heat Treatment Temperature | 2200°C |

Standard & Custom Sizes

| Parameter | Range |

|---|---|

| Thickness | 10 / 15 / 20 / 30 / 40 / 50 / 80 / 150 / 200 mm |

| Width (Board) | 1000 mm / 1200 mm |

| Length (Board) | 1000 mm / 1200 mm / 1500 mm |

| Max Size (Board) | 12” × 48” × 63” |

| Max Circular Plate | 75” × 12” |

| Max Cylinder | 75” × 12” × 48” (Height) |

Special dimensions and CNC-machined parts are available on request.

Packaging and Storage

Packed in plastic film and boxed

Store in dry, ventilated conditions

Shipped as non-dangerous goods