- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

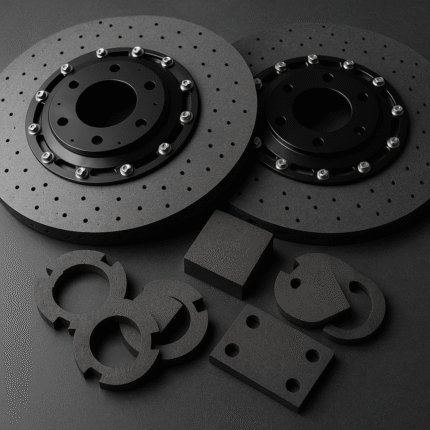

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

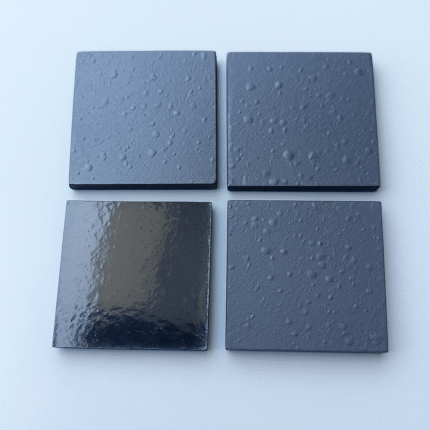

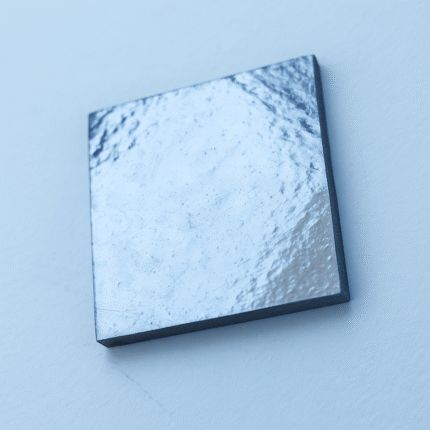

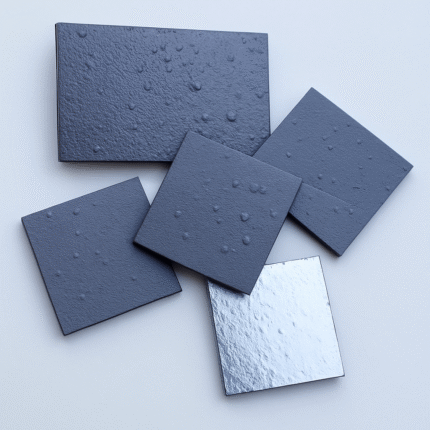

Pyrolytic Graphite Sheets

Pyrolytic graphite sheets are advanced carbon-based materials formed by chemical vapor deposition (CVD) of high-purity hydrocarbon gas onto a graphite substrate at temperatures between 1800–2000 °C under controlled pressure. This process results in an ultra-high crystalline structure with superior anisotropic properties.

Category: Pyrolytic Graphite

Tag: Pyrolytic graphite sheets

Description

Pyrolytic graphite exhibits extremely high purity (impurity content ≤ 0.0002%), high density (approx. 2.20 g/cm³), and outstanding anisotropic thermal, electrical, magnetic, and mechanical performance. It maintains a vacuum of 10 mmHg even at 1800 °C, making it highly suitable for extreme environments.

Typical Properties of Pyrolytic Graphite Sheets:

| Property | Value | Direction |

|---|---|---|

| Grade | Pyrolytic Graphite | – |

| Density | 2.18–2.20 g/cm³ | – |

| Compressive Strength | 83.6 MPa | AB direction |

| Tensile Strength | 75 MPa | AB direction |

| Ash Content | 0.02–0.005% | – |

| Thermal Conductivity | 300–400 W/m·K | AB direction |

| 3.5–5 W/m·K | C direction | |

| Thermal Expansion (C.T.E) | 3.2×10⁻⁶ /℃ | AB direction |

| 17–26×10⁻⁶ /℃ | C direction | |

| Specific Resistance | 2×10⁻⁴ Ω·cm | AB direction |

| 0.6 Ω·cm | C direction | |

| Interlayer Distance (002) | ≤ 3.42 Å | – |

| Air Impermeability (He Transmissivity) | < 10⁻¹⁰ cm² | – |

Available Sizes:

Dia 90×5 mm

90×90×5 mm

90×200×5 mm

Max width: 180 mm

Max length: 800 mm

Max thickness: 10 mm

Applications:

Electronics & Semiconductors: EMI shielding, thermal interface materials

Aerospace: High-temperature insulation, vacuum systems

Medical & Scientific Instruments: Sample holders in high-vacuum environments

Energy Systems: Fuel cells, battery heat dissipation

Metallurgy: Crucible linings, high-purity smelting environments