- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

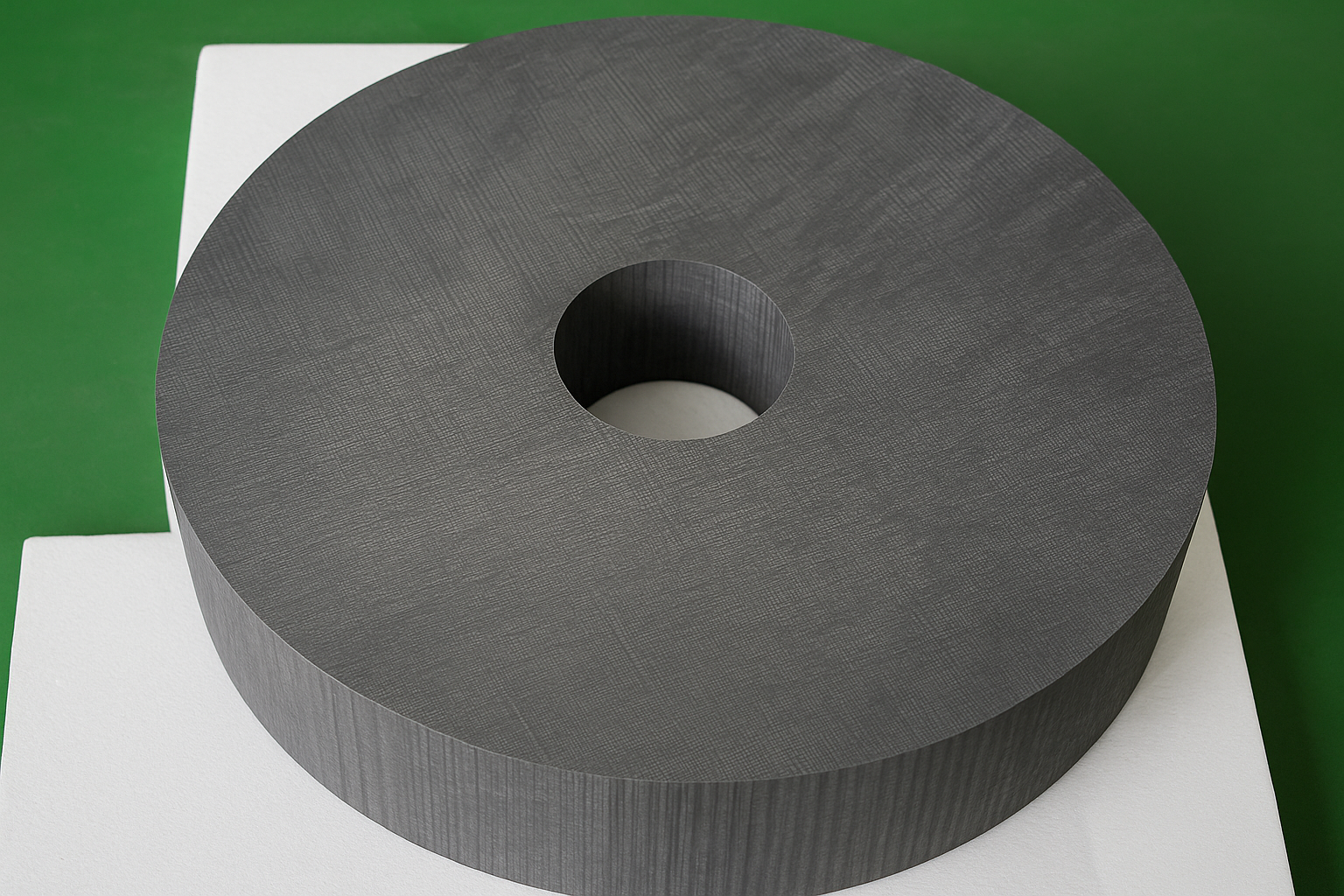

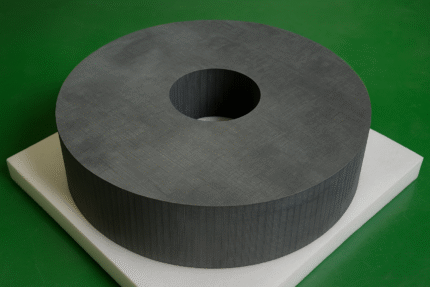

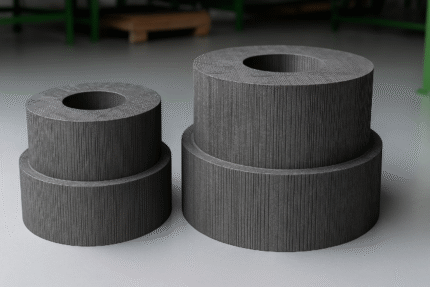

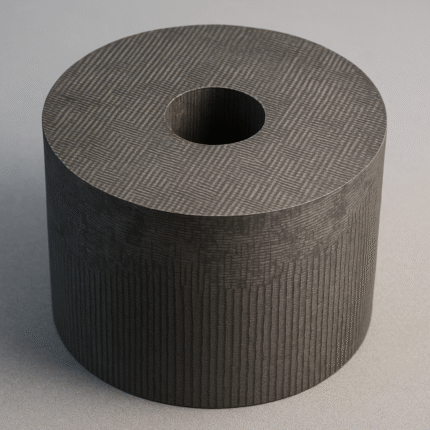

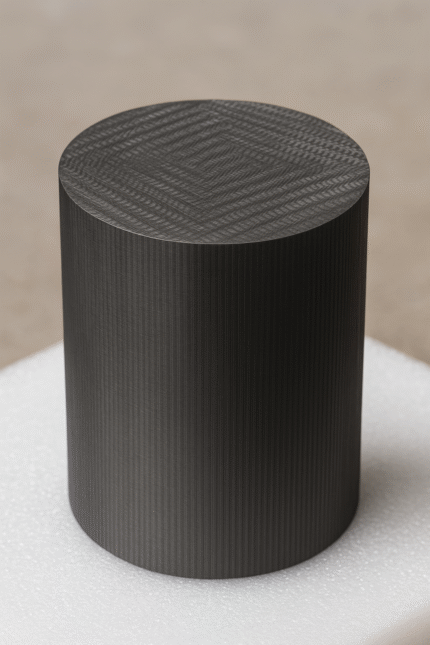

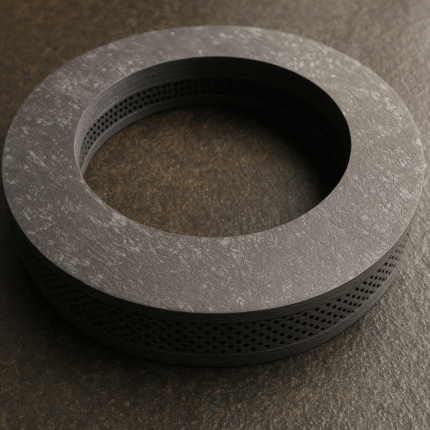

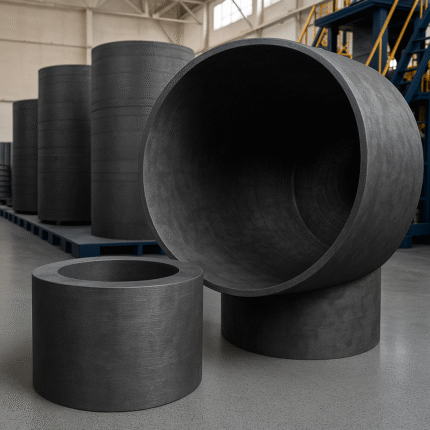

High-Density Carbon-Carbon Composite Materials

BZNCarbon supplies ultra-high density carbon-carbon composites with advanced thermal and structural properties. Suitable for aerospace, energy, and tooling applications requiring superior mechanical integrity.

Category: C-C Composites

Tag: High-Density Carbon-Carbon Composite Materials

Description

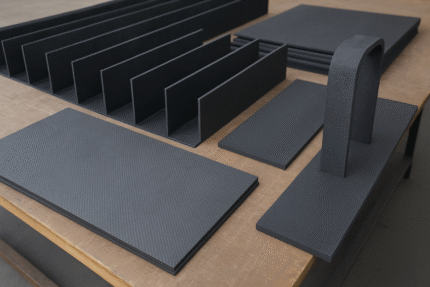

BZNCarbon’s High-Density Carbon-Carbon Composites are engineered to perform in the most extreme thermal, chemical, and mechanical environments. Utilizing advanced processing techniques such as CVD (Chemical Vapor Deposition), CVI (Chemical Vapor Infiltration), and pitch-coke-based infiltration, we produce C/C composites with densities ranging from 1.80 to 1.95 g/cm³.

The resulting materials exhibit superior thermal conductivity, dimensional stability, and strength across all axes. These composites are suitable for demanding applications in aerospace, vacuum furnaces, energy systems, and defense industries.

Whether the design calls for 3D, 4D, Hoop, or custom multi-directional architectures, BZNCarbon can deliver tailored performance with minimal porosity and exceptional service life.

What Is High-Density Carbon-Carbon Composite?

High-density C/C composites are fabricated through high-temperature graphitization and densification of carbon fiber preforms. By selecting optimized infiltration methods (pitch, CVI, or CVD), we minimize open porosity while increasing interlaminar strength and directional conductivity.

These materials are ideal for high-load or high-frequency cycling applications, where conventional materials would fail due to thermal stress or fatigue.

Key Applications

Aerospace braking systems and thermal shields

Rocket nozzle linings and high-pressure insulators

Vacuum furnace platforms and structural fixtures

Industrial high-temperature tooling and molds

Nuclear-grade thermal control panels

Protective liners in gas reactors or foundries

Technical Specifications

| Property | Unit | Direction | Standard | Tested Value |

|---|---|---|---|---|

| Bulk Density | g/cm³ | — | ≥1.80 | 1.85 |

| Tensile Strength | MPa | XY / Z | ≥60 / ≥30 | 169 / 95 |

| Tensile Modulus | GPa | XY / Z | ≥50 / ≥30 | 59.9 / 35.8 |

| Bending Strength | MPa | XY / Z | ≥80 / ≥40 | 140 / 80 |

| Compressive Strength | MPa | XY / Z | ≥85 / ≥85 | 120 / 282 |

| Shear Strength | MPa | XY / Z | ≥30 / ≥25 | 65 / 49 |

| Thermal Conductivity (900°C) | W/m·K | XY / Z | ≥40 / ≥20 | 62.2 / 25.1 |

| Thermal Expansion (1000°C) | 10⁻⁶/K | XY / Z | ≤2.0 / ≥3.0 | 1.1 / 1.14 |

| Graphitization Level | % | — | ≥60 | 75.5 |

| Specific Heat Capacity | kJ/kg·K | — | ≥1.2 | 1.53 |

Additional inspection: X-ray screening, porosity control, custom geometries available.

Benefits

Extremely high thermal conductivity in all directions

Low porosity, high-density matrix for dimensional stability

Withstands repeated thermal cycling at temperatures >2000°C

Long lifespan under vacuum or chemically reactive conditions

Custom-formulated fiber orientations and densities available

Low thermal expansion prevents structural distortion