- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

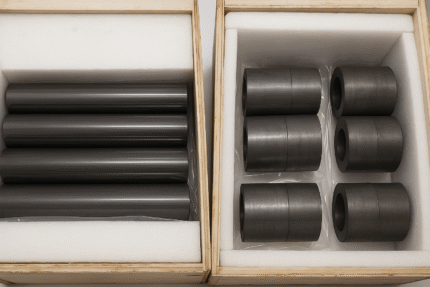

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

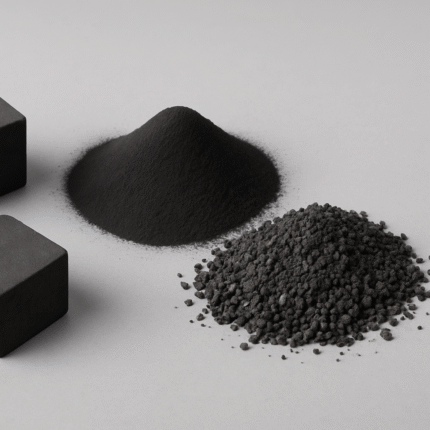

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

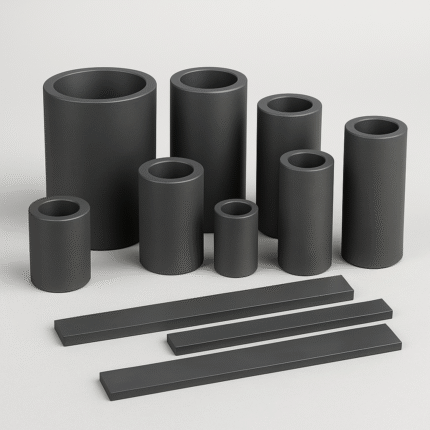

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

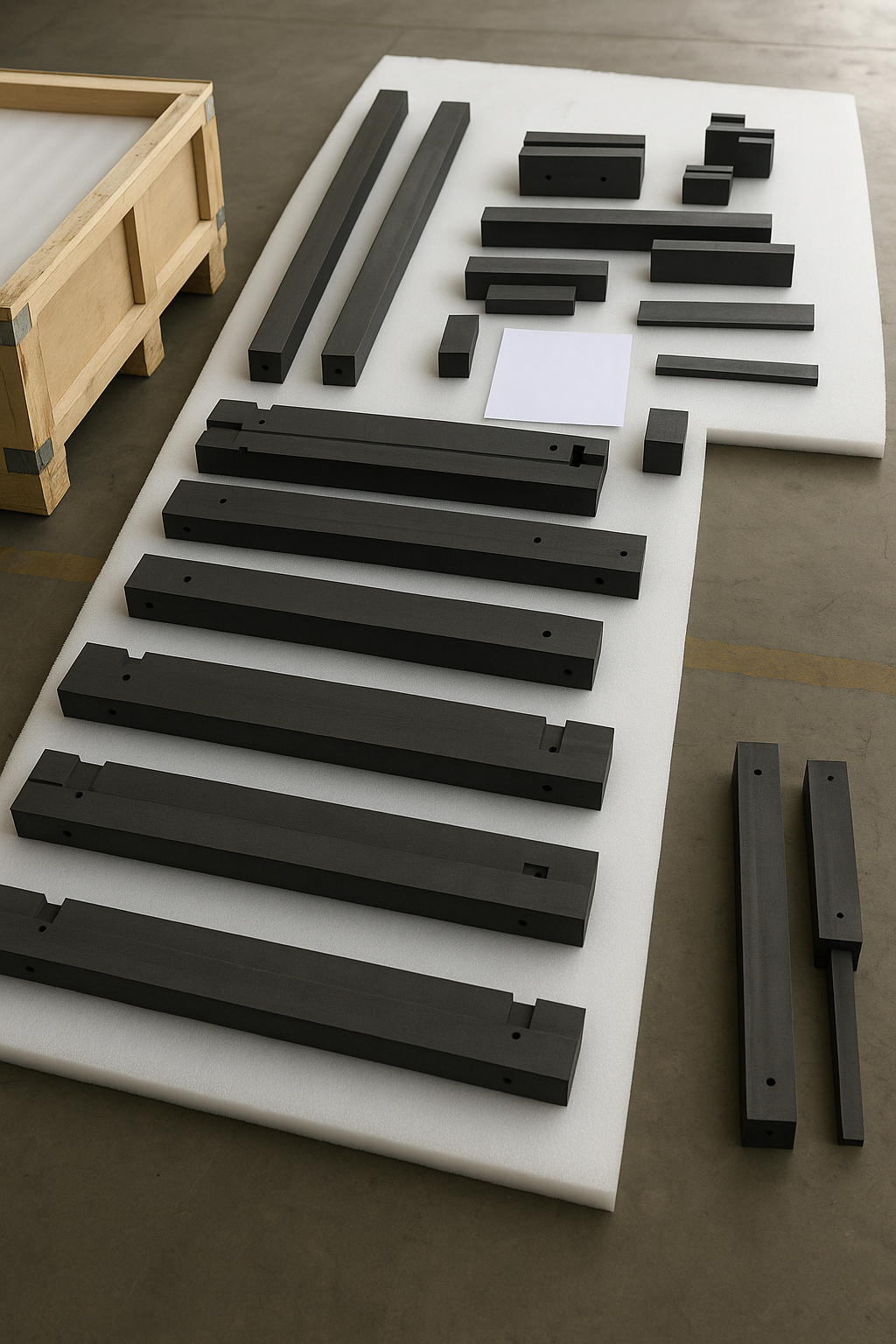

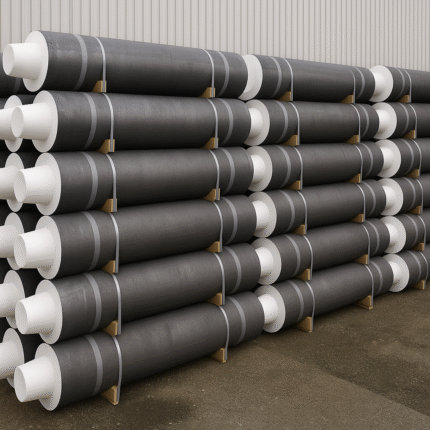

Graphite Products for Glass Industry

BZNCarbon supplies high-performance, precision-machined graphite components specifically designed for the glass industry. With excellent resistance to deformation at elevated temperatures and low wettability to molten glass and metal, graphite is the ideal material for use in the float glass and glass bottle production processes.

Our graphite products are available in large sizes and high-strength formulations, and can be custom-machined to meet a variety of industrial needs. For enhanced durability, we also offer anti-oxidation treatment to extend product service life under high-temperature, oxygen-rich conditions.

Category: Graphites

Tag: Graphite Products for Glass Industry

Description

Material Specifications

| Application | Bulk Density (g/cm³) | Specific Resistance (μΩ·m) | Flexural Strength (MPa) | Compressive Strength (MPa) | Ash (%) | Grain Size (mm) |

|---|---|---|---|---|---|---|

| For Barriers | 1.72 | 9 | 13 | 30 | 0.2 | 0.8 |

These are reference values and can be adjusted based on customer application requirements.

Product Description

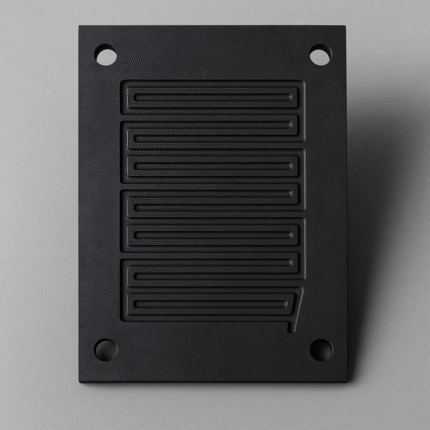

Graphite’s non-reactive surface and high-temperature stability make it essential in many stages of glass production. Key applications include:

Float Glass Production

Graphite barriers and supports in tin bath walls, often up to 3–4 meters in length, provide structural guidance and containment for the float glass process. These components are dimensionally stable and resist wear even under intense heat and chemical exposure.Glass Bottle Molding

Graphite molds and fixtures offer precise shaping and easy release in bottle forming applications, where thermal cycling and surface smoothness are critical.

To ensure protection during long-distance shipping, our large-format graphite components are specially packed to prevent cracking, chipping, or deformation.

Processing Capabilities

Sawing

Turning

Milling

Grinding

CNC Machining

BZNCarbon’s processing lines are optimized for customized machining according to drawings. We evaluate each project’s precision requirements and choose the most efficient processing path to reduce cost and delivery time.

Related products

Select options

This product has multiple variants. The options may be chosen on the product page