- Graphites

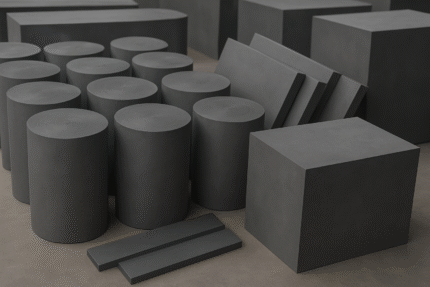

- Isostatic Graphite

- Molded Graphite

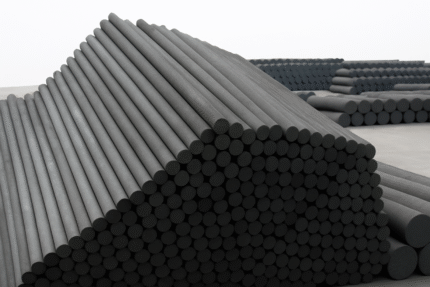

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

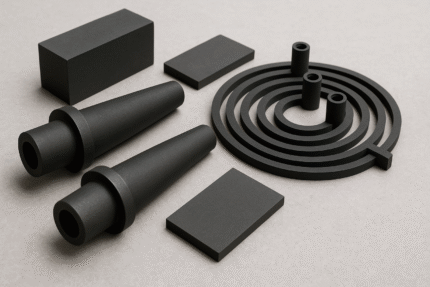

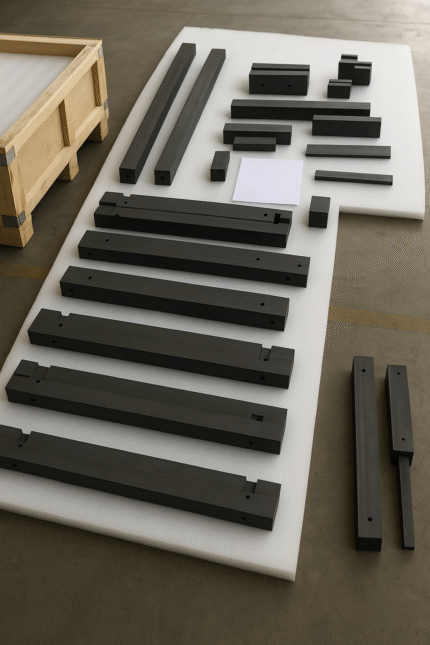

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

Graphite Hot Zone for PV

BZNCarbon produce and supply precision-machined graphite components specifically designed for hot zone use in PV applications. With multiple CNC machining centers and three-coordinate measuring systems, we guarantee high dimensional accuracy. Additionally, our advanced purification furnaces enable ash reduction to levels below 2 PPM when needed.

Category: Graphites

Description

Material Specifications

| Grade | Bulk Density (g/cm³) | Specific Resistance (μΩ·m) | Flexural Strength (MPa) | Compressive Strength (MPa) | Ash (Normal) % | Ash (Purified) (ppm) | Grain Size (μm) |

|---|---|---|---|---|---|---|---|

| BZ-11 | 1.83 | 11–13 | 50 | 115 | 0.05 | 50 | 8–10 |

| BZ-12 | 1.90 | 11–13 | 61 | 135 | 0.05 | 50 | 8–10 |

| BZ-13 | 1.78 | ≤13 | 46 | 86 | 0.05 | 50 | – |

| BZ-14 | 1.86 | 11–12 | 65 | 135 | 0.05 | 50 | 5 |

| BZ-22 | 1.80 | 13–14 | 55 | 100 | 0.02 | – | 8 |

| BZ-23 | 1.86 | 9–12 | 55 | 110 | 0.05 | – | 13 |

| BZ-31 | 1.79 | 11–13 | 38 | 78 | 0.05 | – | – |

| BZ-32 | 1.85 | 11–13 | 45 | 100 | 0.05 | – | – |

Product Overview

With the growth of the photovoltaic industry, the demand for high-quality materials has rapidly increased. Polysilicon ingot production, an essential process in solar wafer manufacturing, heavily relies on high-purity graphite materials.

Why Graphite?

Graphite is used throughout the PV manufacturing chain — from quartz smelting to polysilicon production and monocrystalline growth — due to its:

Excellent high-temperature resistance

Outstanding thermal stability

High density and compressive strength

Superior corrosion resistance and electrical conductivity

We achieve ultra-high purity levels (ash content < 2 PPM) through our proprietary purification techniques, making our products ideal for cleanroom-level PV processes.

Typical Applications

Graphite electrodes

Graphite heaters

Graphite crucibles

Heat insulation shielding plates

Heat reflection plates

Structural graphite components in hot zones

Production Process

Raw Material Crushing

Screening

Mixing & Kneading

Cold Isostatic Pressing (CIP)

Baking

Impregnation

Re-Baking

Graphitization

CNC Machining

Purification

Inspection

Packaging

Packaging & Shipping

We use vacuum packaging for high-purity graphite parts. Based on customer preferences, we provide customized packaging including wooden boxes and pallet solutions for safe international delivery.

Related products

Select options

This product has multiple variants. The options may be chosen on the product page

Calcined Petroleum Coke

150,00 €

Select options

This product has multiple variants. The options may be chosen on the product page