- Graphites

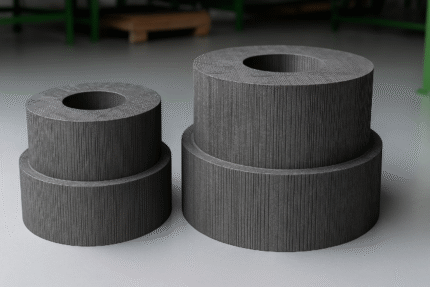

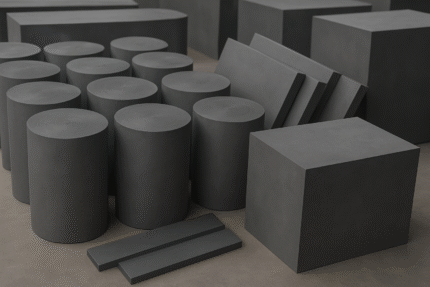

- Isostatic Graphite

- Molded Graphite

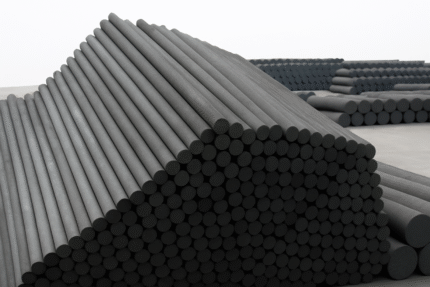

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

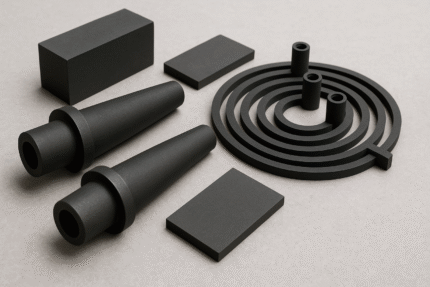

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

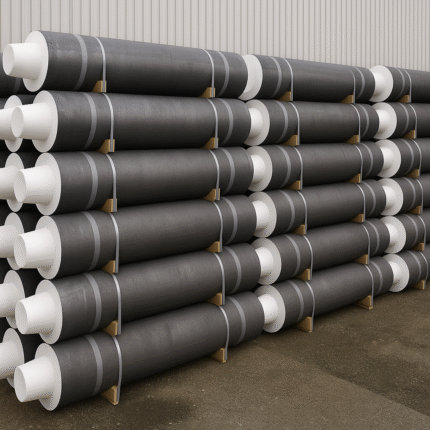

- Graphite Electrode

- Graphite Bipolar Plate

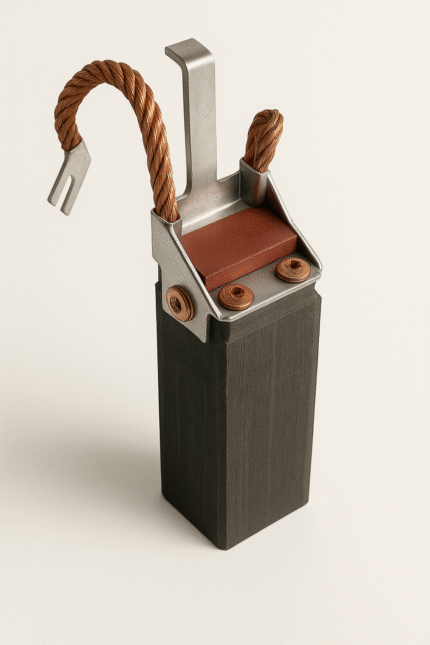

- Carbon Brush/Electric Brush

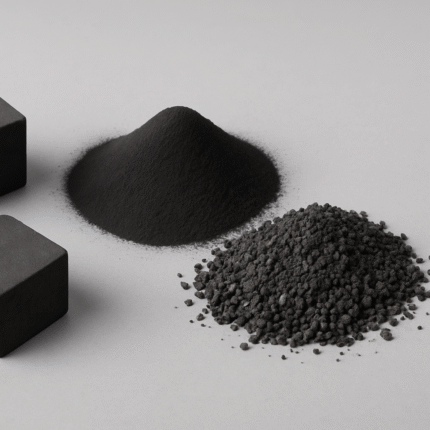

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

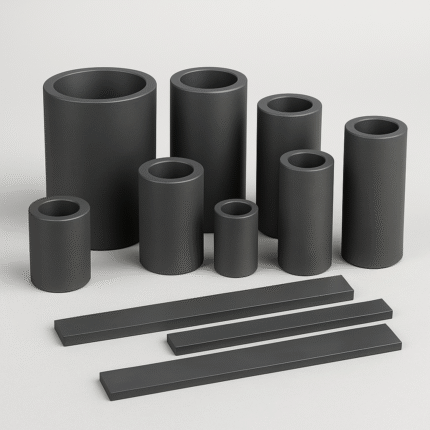

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

Graphite Crucible

At BZNCarbon, we produce two main types of graphite crucibles:

Machined Graphite Crucibles (High-Purity Type)

Graphite Clay Crucibles (SiC Graphite Type)

Each type is tailored to meet specific industrial melting applications based on thermal and chemical performance requirements.

Category: Graphites

Tag: Graphite Crucible

Description

Why Graphite?

The primary material used in our graphite crucibles is natural crystalline graphite, which retains the excellent physical and chemical properties of natural graphite:

High thermal conductivity

High-temperature resistance

Low thermal expansion under heat

Strong thermal shock resistance

Excellent chemical stability in acidic or alkaline environments

Corrosion resistance and material purity retention

Applications

Graphite crucibles are widely used in:

Alloy and tool steel smelting

Non-ferrous metal casting (copper, aluminum, gold, etc.)

Metallurgy, chemical, foundry, machinery industries

Their flexibility in shape and size allows custom manufacturing without limits on batch size, making them ideal for specialized or high-volume production.

1) Machined Graphite Crucibles

Also known as high-purity crucibles, these are manufactured from:

Isostatic graphite

Molded graphite

Custom-made according to client drawings, they include:

Steel melting crucibles

Copper melting crucibles

Gold refining crucibles

Uranium salt graphite crucibles

Gold crucibles require materials with:

Bulk density > 1.85 g/cm³

Ash content < 50 ppm

Fine grain structure

Uranium salt crucibles are large-sized and made using multiple processes: extrusion/molding, roasting, impregnation, and graphitization. Typical sizes:

Φ400mm × 700mm

Φ500mm × 800mm

2) Graphite Clay Crucibles (SiC Graphite Crucibles)

These are made from a mix of graphite and silicon carbide (SiC) and are widely used for:

Melting copper

Melting aluminum

Other general-purpose metal casting

They are:

Low-cost

High-capacity

Manufactured using pressure-forming methods

Crucible Use Guidelines

Store in a dry area to prevent moisture absorption

Preheat gradually to 500°C before first use

Avoid overpacking to prevent cracking

Scoop melted metal instead of using tongs when possible

If tongs are used, their shape should match the crucible’s curve to minimize stress

Related products

Select options

This product has multiple variants. The options may be chosen on the product page