- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

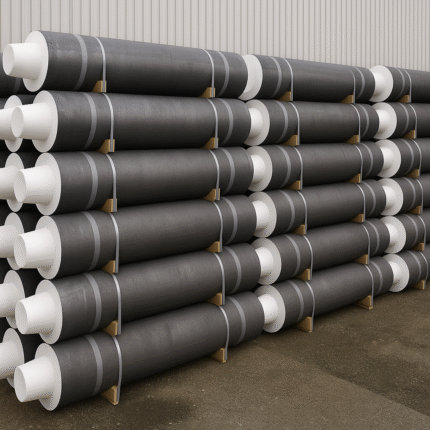

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

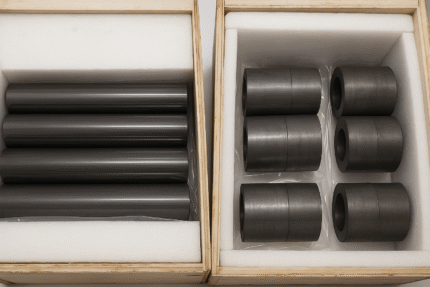

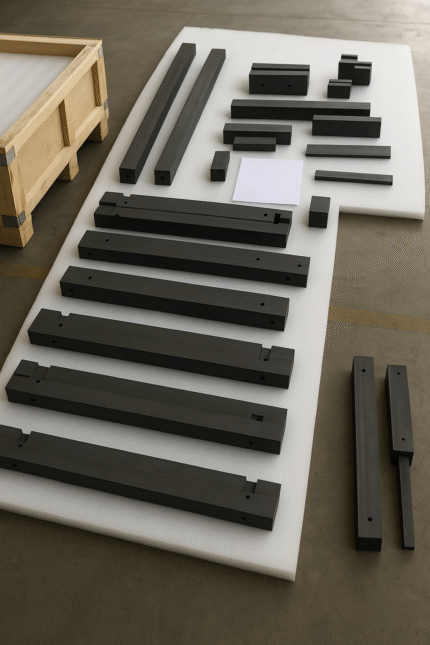

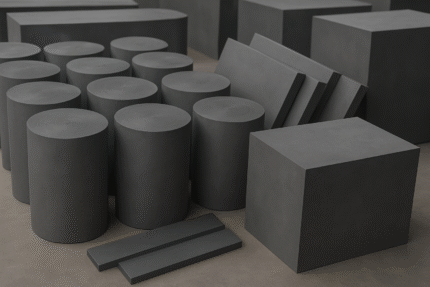

Graphite Box for Anode Material

BZNCarbon has extensive expertise in manufacturing and machining graphite boxes tailored for the lithium-ion battery sector. These graphite boxes are primarily used during the carbonization and graphitization stages of battery anode materials. Leveraging CNC technology and custom production capabilities, we provide cost-effective solutions that combine structural integrity with functional efficiency.

Category: Graphites

Tag: Graphite Box for Anode Material

Description

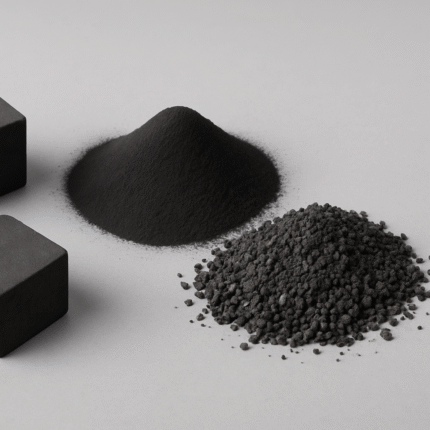

Material Specifications

| Grade | Bulk Density (g/cm³) | Specific Resistance (μΩ·m) | Flexural Strength (MPa) | Compressive Strength (MPa) | Ash (ppm) | Grain Size |

|---|---|---|---|---|---|---|

| ZV-10 | 1.60 | 10 | 15 | 28 | 0.2 | 0.8 mm |

| ZM-20 | 1.80 | 9 | 38 | 75 | 0.1 | 25 μm |

These are standard values provided for reference purposes.

Product Description

With the rapid growth of the new energy vehicle industry, lithium battery production has significantly increased. One of the essential processes in lithium battery material preparation is the thermal treatment of anode materials like lithium iron phosphate or sodium-ion compounds.

Graphite boxes are critical during high-temperature processes such as:

Carbonization

Graphitization

Powder stabilization

These processes ensure the stability and electrical performance of battery-grade carbon materials.

Key Features

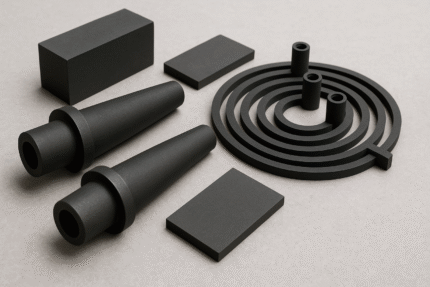

Increased capacity: The square shape allows maximum space usage within furnaces, especially at the corners, improving powder load volume per cycle.

Long service life: High-density and high-strength graphite ensures resistance to thermal and mechanical stress.

Cost efficiency: Our proprietary machining reduces raw material waste, delivering both performance and value.

Custom design: Available in a variety of dimensions and finishes, based on customer drawings and precision requirements.

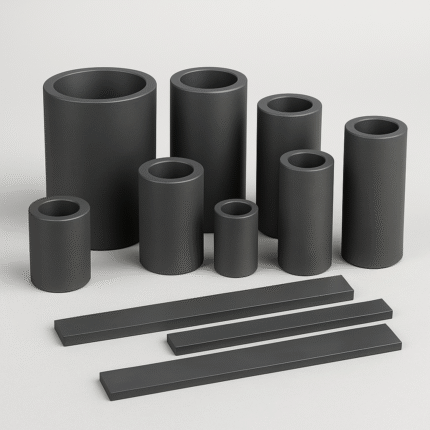

Machining Capabilities

Grinding

Sawing

Turning

Milling

CNC Precision Machining

With flexible production lines and technical expertise, BZNCarbon selects the optimal processing technology for each project, ensuring short lead times and high accuracy.

Related products

Select options

This product has multiple variants. The options may be chosen on the product page

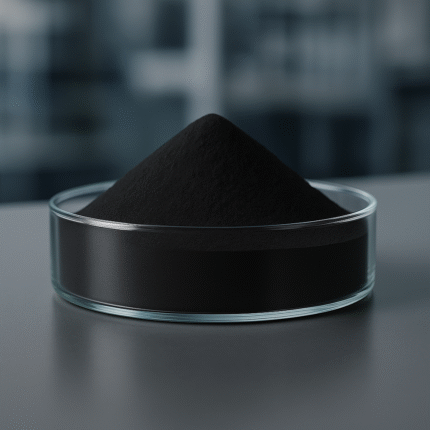

Expanded Graphite Powder – High Conductivity Grade BZ-20

250,00 €

Select options

This product has multiple variants. The options may be chosen on the product page