- Graphites

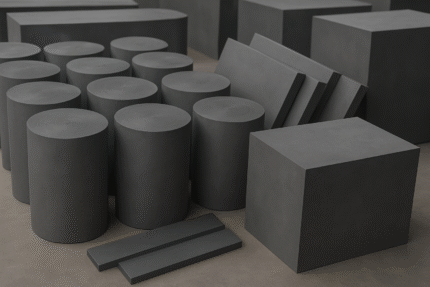

- Isostatic Graphite

- Molded Graphite

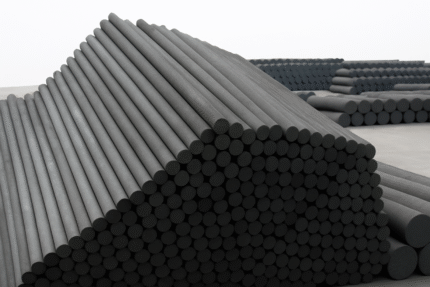

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

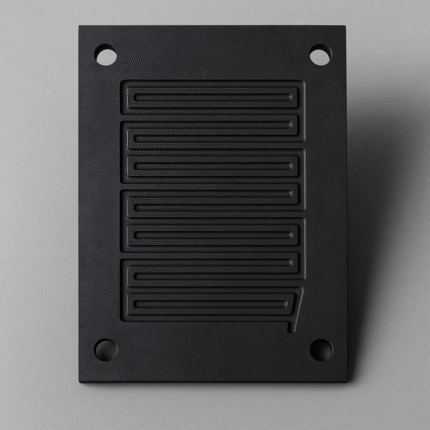

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

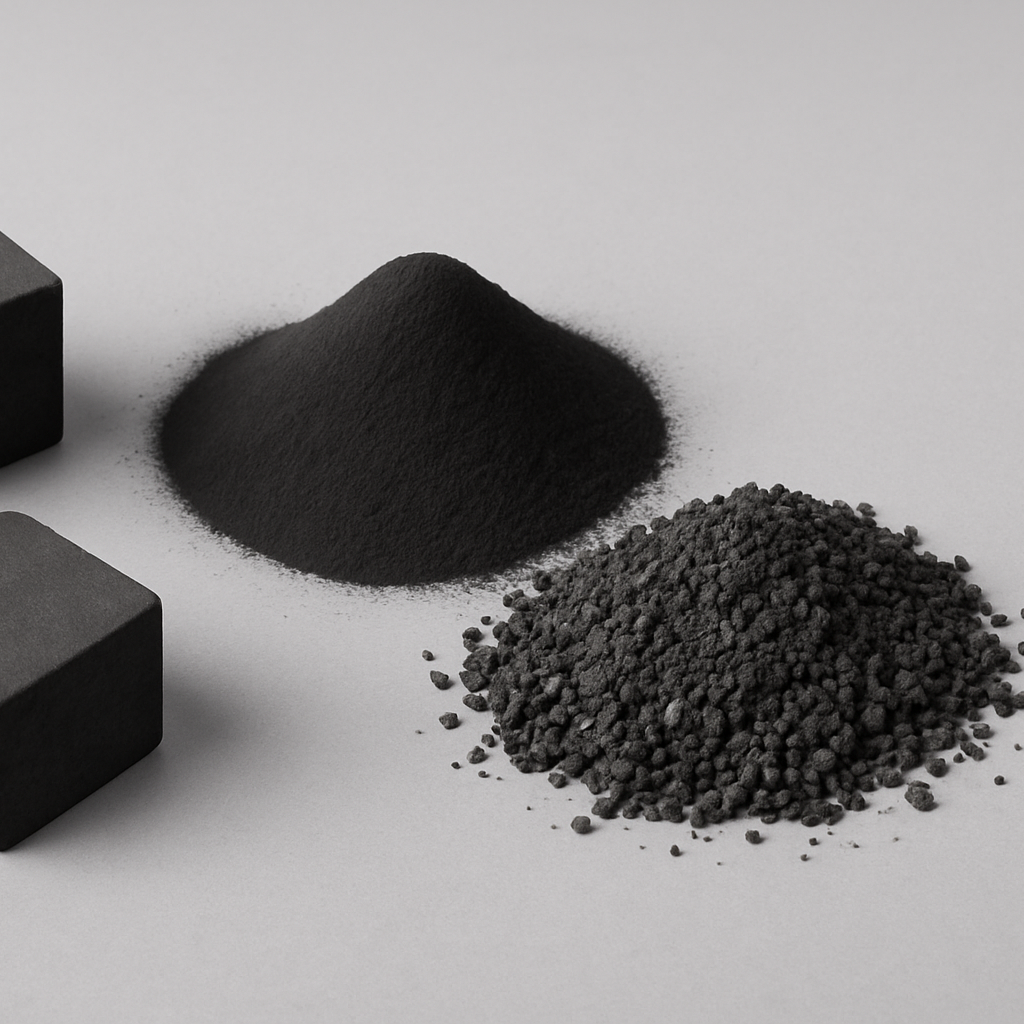

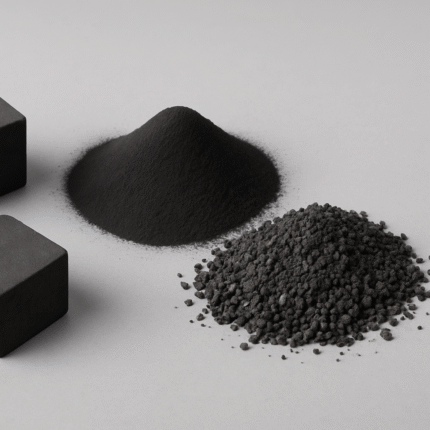

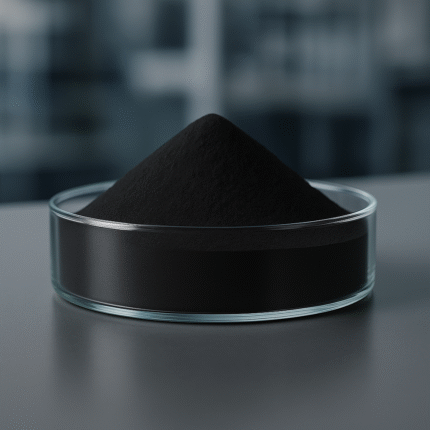

Expanded Graphite Powder – High Conductivity Grade BZ-20

250,00 €

BZNCarbon’s expanded graphite powders are engineered to deliver superior thermal and electrical performance in demanding environments. Manufactured through a controlled exfoliation process, these powders feature a low tap density, high surface area, and excellent purity, making them highly effective in applications where heat dissipation, conductivity, or chemical inertness is essential.

Contact us for competitive pricing on orders exceeding 50 kg

Description

| Grade | Particle Size D₅₀ (µm) | Tap Density (g/cm³) | Real Density (g/cm³) | BET Surface Area (m²/g) | Ash Content (%) | Carbon Content (%) | Moisture (%) |

|---|---|---|---|---|---|---|---|

| BZ-20 | 20 | 0.11 | 2.25 | 30 | ≤ 3.0 | ≥ 97.0 | < 0.5 |

What Is Expanded Graphite Powder?

Expanded graphite is produced by thermally exfoliating natural graphite flakes, resulting in a voluminous and porous powder. This structure enhances heat and electron transport while reducing weight and improving compatibility with various industrial matrices. Its performance characteristics make it a functional additive for advanced composite systems.

Expanded graphite is a lightweight, porous form of graphite that retains the high thermal conductivity, chemical resistance, and structural flexibility of its crystalline structure while achieving superior dispersibility in polymer, resin, and fluid systems. Its lamellar morphology allows for efficient particle-to-particle contact, enabling optimal performance in thermal interface and conductive systems.

Main Applications

Our expanded graphite powders are engineered for versatility across a broad range of industries:

Thermal Interface Materials (TIMs): Efficient filler in gap pads, pastes, and conductive foams for electronics cooling and heat dissipation in EV batteries, CPUs, LEDs, and power modules.

Electrically Conductive Composites: Used in conductive plastics, coatings, and films for ESD protection and EMI shielding in automotive, aerospace, and electronics.

Battery Technologies: EG-75-L grade supports conductivity and structural reinforcement in lithium-ion and sodium-ion battery electrodes and coatings.

Lubricants and Greases: EG-75-L also serves as an oxidation-resistant additive in high-temperature and high-load lubricant formulations.

Sealants and Adhesives: Improves dimensional stability, thermal transfer, and chemical resistance in structural adhesives and flexible sealants.

Flame Retardant Systems: Acts as a heat-spreading agent and char-forming filler in halogen-free flame retardant polymer systems.

Foundry and Mold Release Applications: Functions as a thermal barrier and parting agent in metal casting and glass shaping.

Additional information

| Kilogram |

1kg ,5kg ,10kg ,50kg |

|---|

Related products

Select options

This product has multiple variants. The options may be chosen on the product page

Expanded Graphite Powder – High Conductivity Grade BZ-75

200,00 €

Select options

This product has multiple variants. The options may be chosen on the product page