- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

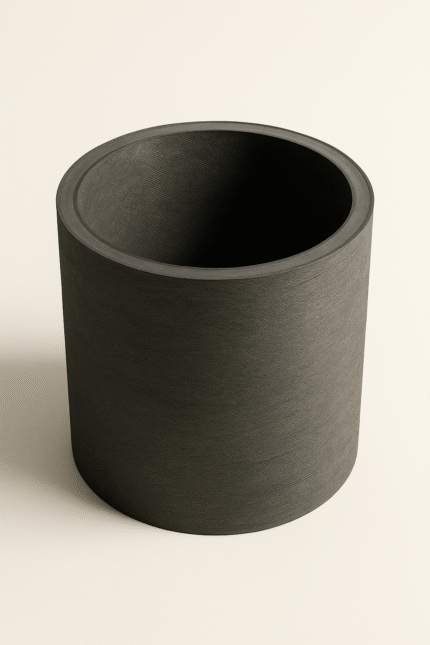

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

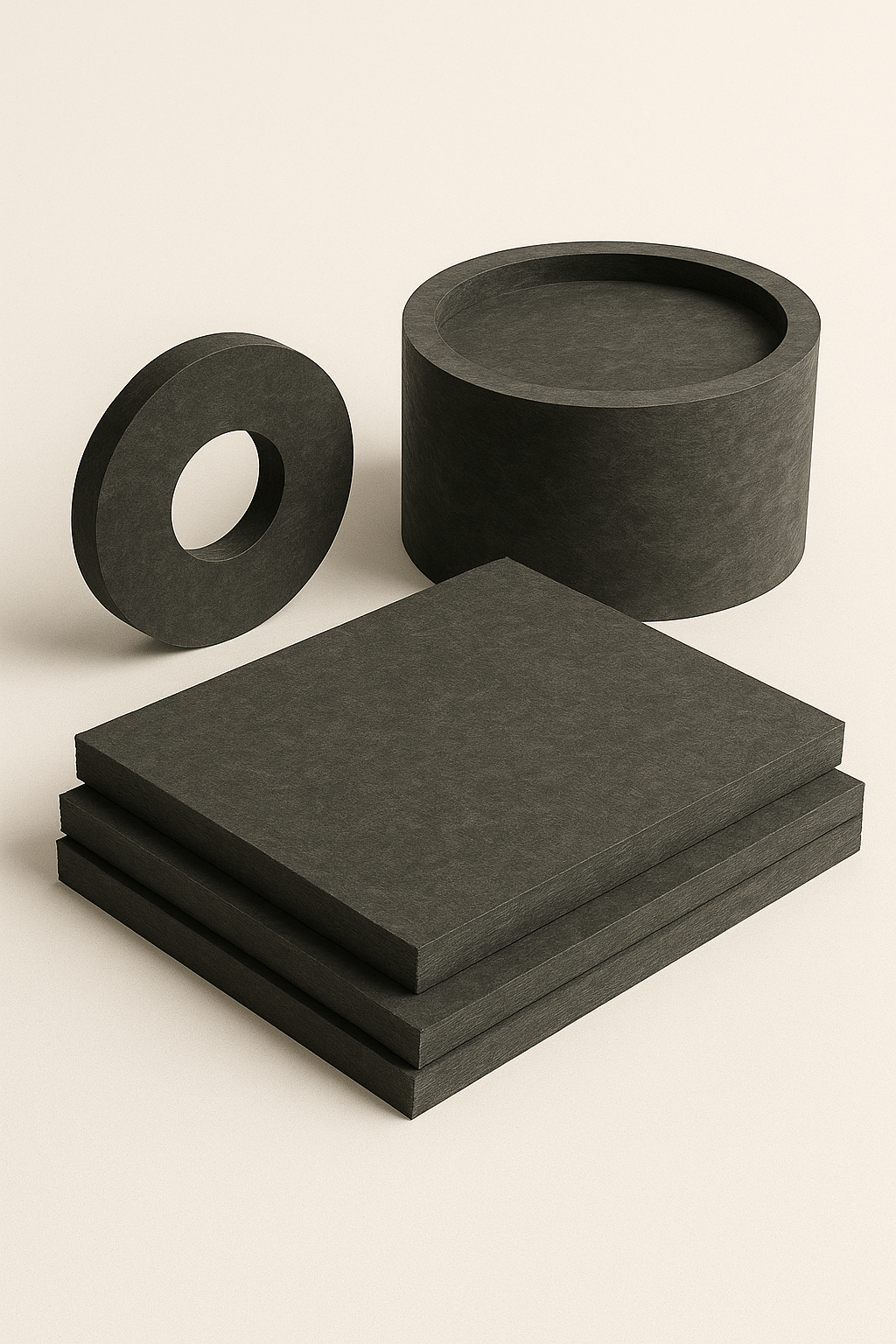

- 2D

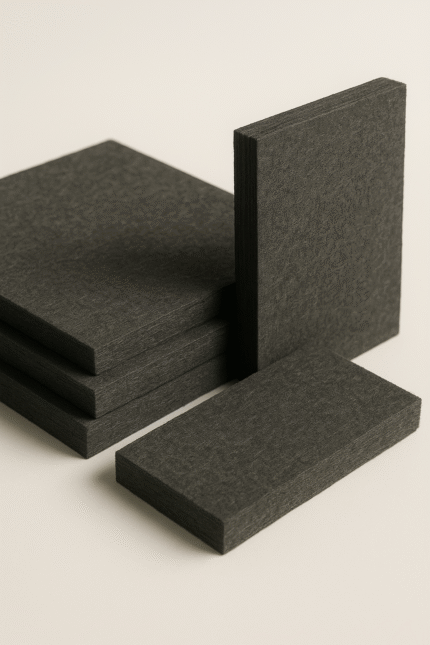

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

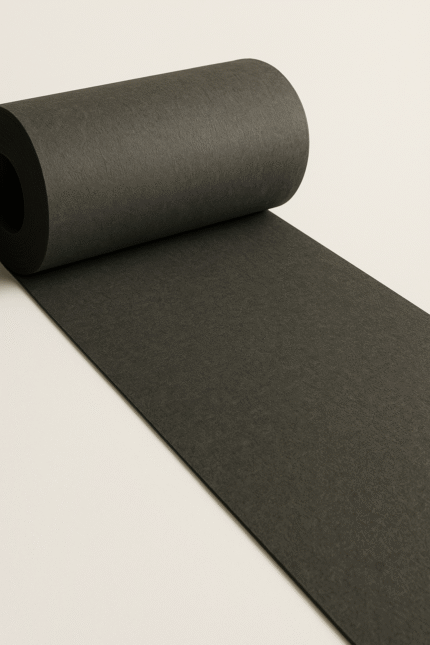

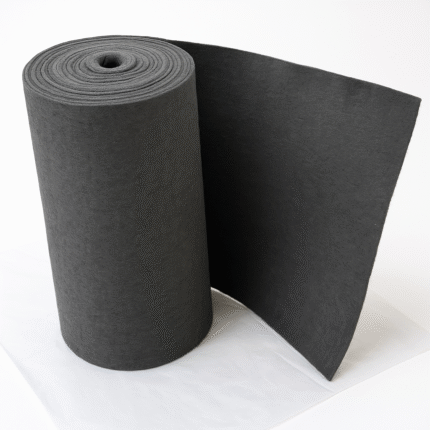

- Carbon Felt / Graphite Felt

Chopped Fiber&Short Fiber Insulation Felt

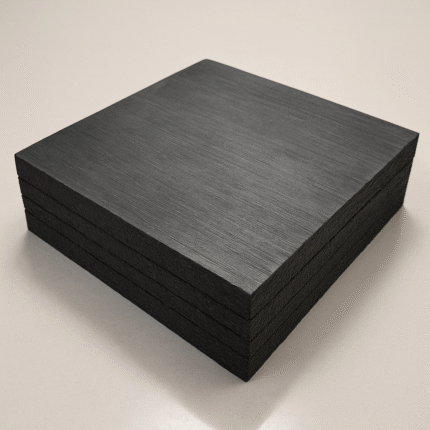

BZNCarbon’s chopped fiber (or short fiber) insulation graphite felt is a next-generation high-temperature insulating material. Unlike layered rigid felt, this type is an integral monolithic structure, meaning the entire block is formed in one piece without lamination. This unique structure provides superior thermal insulation and mechanical stability in demanding furnace environments.

Category: Carbon Felt / Graphite Felt

Tags: Chopped Fiber, Short Fiber Insulation Felt

Description

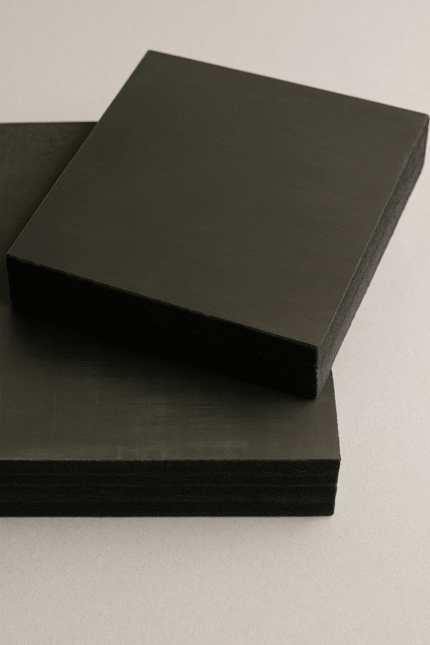

Chopped fiber insulation felt is produced by vacuum-molding short carbon fibers into a single, seamless rigid block or shape. The fibers are directionally distributed using a vacuum slurry system, followed by curing, carbonization, and high-temperature treatment under inert gas or vacuum protection.

The result is a dense, non-delaminating, low-conductivity insulation material suitable for extreme conditions, with superior compressive and flexural strength compared to traditional rigid graphite felts.

Application Areas

Crystal growth furnaces (Czochralski and Bridgman methods)

Vacuum and inert gas high-temperature furnaces

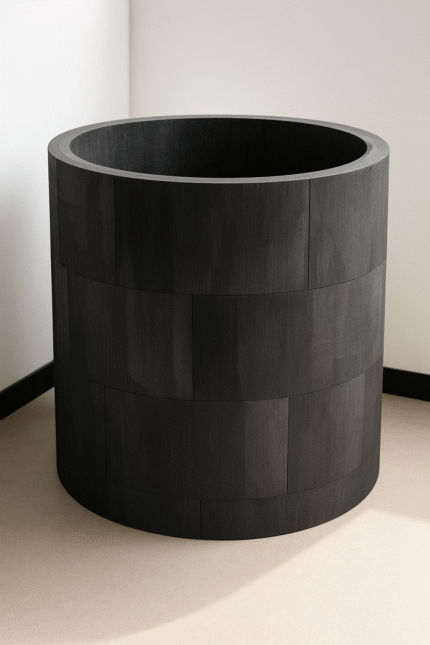

Thermal insulation barrels and cylinders

Graphite-lined reactors

Nuclear and aerospace insulation

Energy storage systems requiring structural and thermal performance

Production Highlights

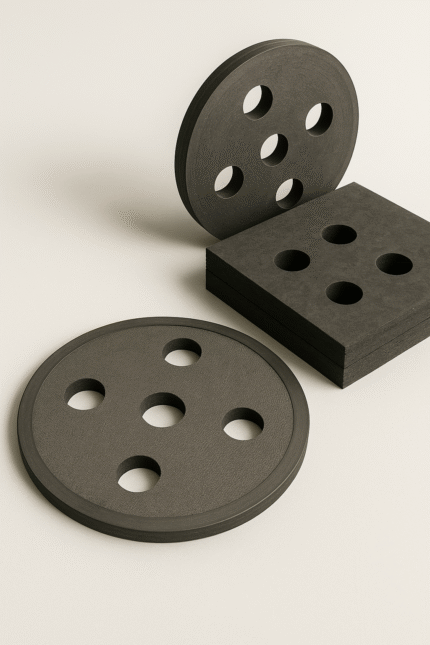

Molded using inner and outer cylindrical forms with vacuum ports

Precise fiber alignment through water flow shaping

Resin-carbon fiber slurry mixture molded and heat-treated

Single-piece formation—no layering or laminating required

Cost-effective and structurally efficient for insulation barrels

Technical Specifications

| Property | Unit | Standard Value | Measured |

|---|---|---|---|

| Density | g/cm³ | 0.13–0.16 | 0.15 |

| Thermal Conductivity | W/m·K (1000°C) | ≤0.20 | 0.18 |

| Compressive Strength | MPa | ≥0.20 | 0.34 |

| Flexural Strength | MPa | ≥3.50 | 4.90 |

| Ash Content | ppm | ≤3000 | 1487 |

Standard Size (Stocked)

| Parameter | Size (mm) |

|---|---|

| Nominal Size | 1600 × 1600 × 50 |

| Trimmed Size | 1550 × 1550 × 50 (min) |

Custom shapes and thicknesses available upon request. Large stock available.