- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

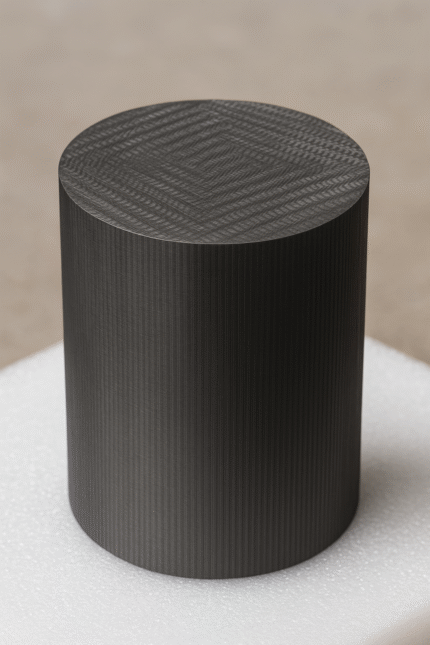

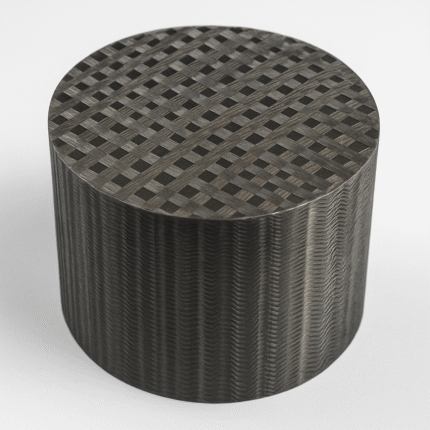

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

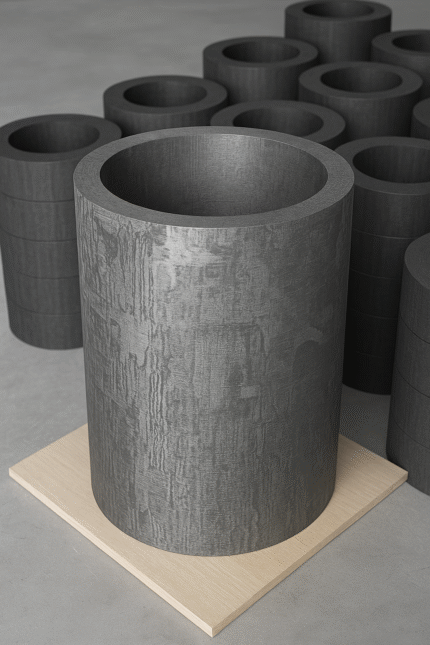

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

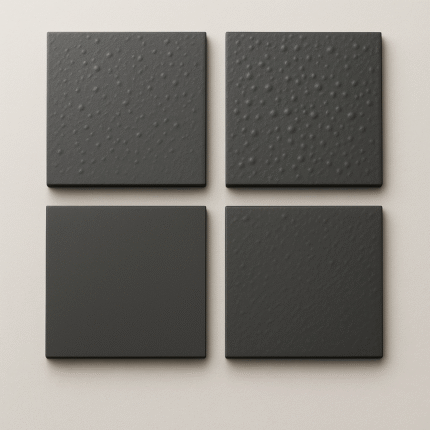

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

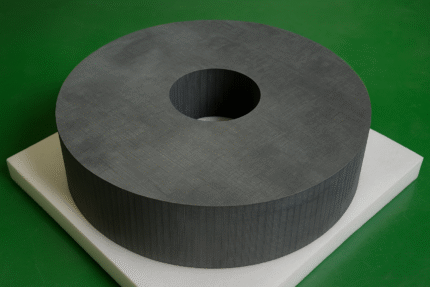

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

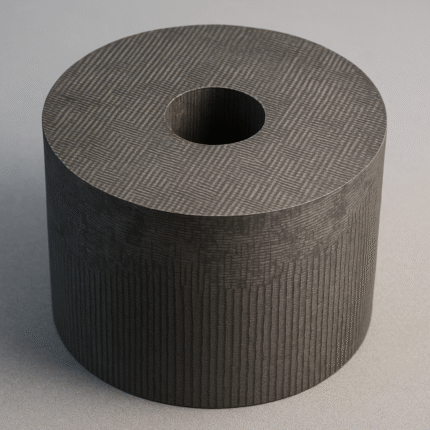

- Carbon Carbon Composite Blocks

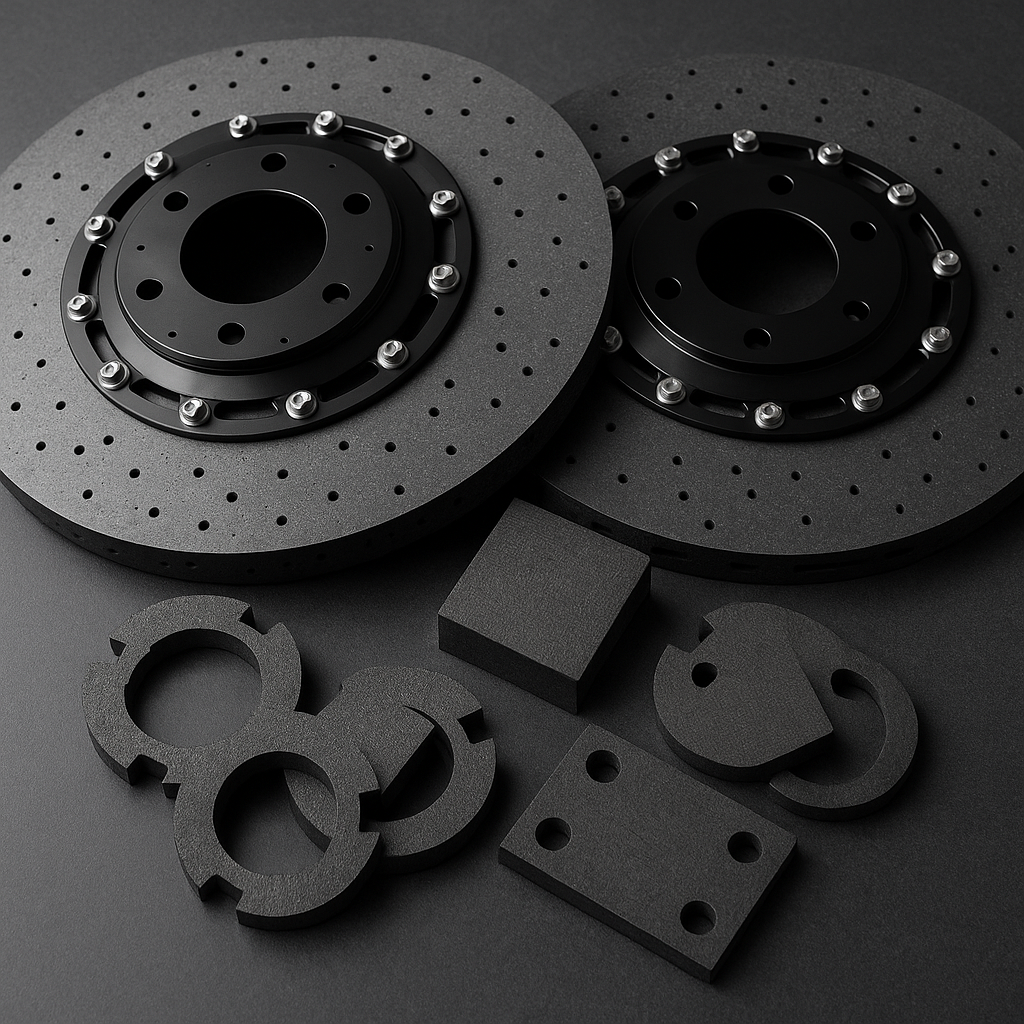

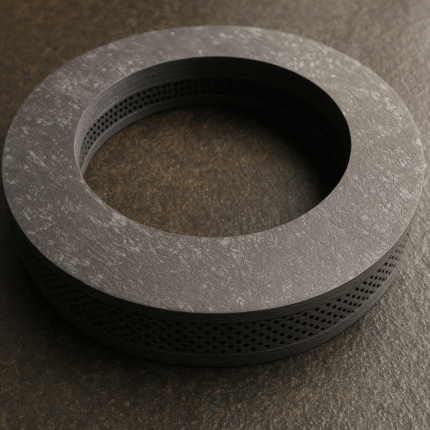

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

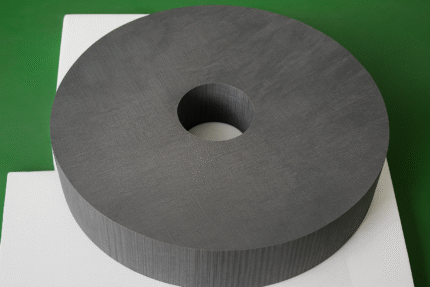

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

Carbon Ceramic Composite Materials and Precision Parts

BZN Carbon is a trusted provider of high-performance carbon ceramic composite materials and components, engineered for demanding thermal and mechanical environments. We offer a range of advanced C/SiC (carbon fiber-reinforced silicon carbide) products, designed with long-term durability, lightweight performance, and excellent thermal resistance in mind.

Description

BZN Carbon is a trusted provider of high-performance carbon ceramic composite materials and components, engineered for demanding thermal and mechanical environments. We offer a range of advanced C/SiC (carbon fiber-reinforced silicon carbide) products, designed with long-term durability, lightweight performance, and excellent thermal resistance in mind.

What Is Carbon Ceramic Composite?

Carbon ceramic composite, often referred to as Cf/C-SiC or C/SiC, is a hybrid material made of carbon fibers embedded in a silicon carbide ceramic matrix. This structure combines the hardness and heat resistance of ceramics with the toughness and flexibility of carbon fibers, delivering a mechanical strength up to five times greater than steel — at a fraction of the weight.

Key Features and Advantages

Low Density: Ideal for weight-sensitive applications like motorsports and aerospace

Outstanding Thermal Stability: Operational performance at temperatures up to 1650°C

Superior Oxidation & Corrosion Resistance: Excellent for extreme environments

Exceptional Strength & Toughness: Maintains structural integrity under thermal shock

Extended Service Life: Great wear resistance with consistent friction performance

Applications of BZN Carbon’s Ceramic Composites

Our carbon ceramic materials are used in a wide variety of high-tech and industrial applications, including:

Racing and High-Performance Automotive Brake Discs

Aerospace Thermal Shielding and Structural Components

Aviation Brake Systems and Rotor Disks

Defense and Ballistics Armor Panels

Industrial Furnace Insulation and Heat Shields

Additionally, carbon ceramic brakes are increasingly replacing cast iron in sports and performance cars. C/SiC brake discs are often paired with C/C composite brake pads (organic pads), providing optimal wear resistance and thermal dissipation in both dry and high-speed braking conditions.

Product Configurations

We manufacture custom carbon ceramic parts tailored to your specifications. Options include:

Solid or perforated discs

Rotor shapes

Caliper-matching geometries

Heat-treated surface finishes

Custom density, porosity, or layer configuration is available upon request.

Why Choose BZN Carbon?

Materials Expertise: Over a decade of experience in carbon-carbon and carbon-ceramic composites

In-House Manufacturing: From raw C/SiC material to finished components

Precision Engineering: CNC machining and CVD/CVI processing capability

Global Service: Export-ready with full QA documentation and support