- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

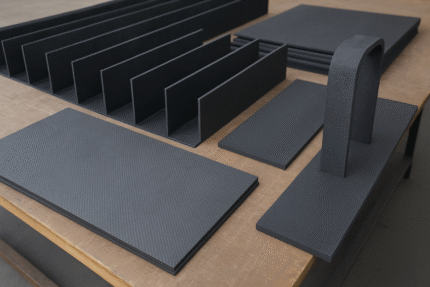

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

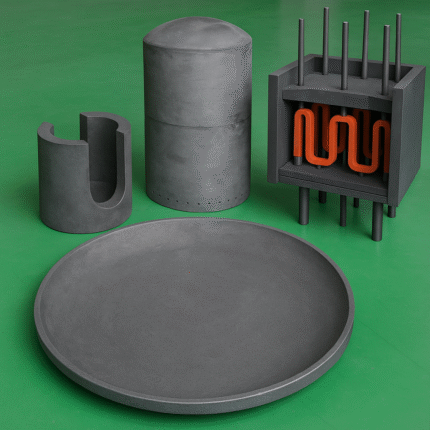

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

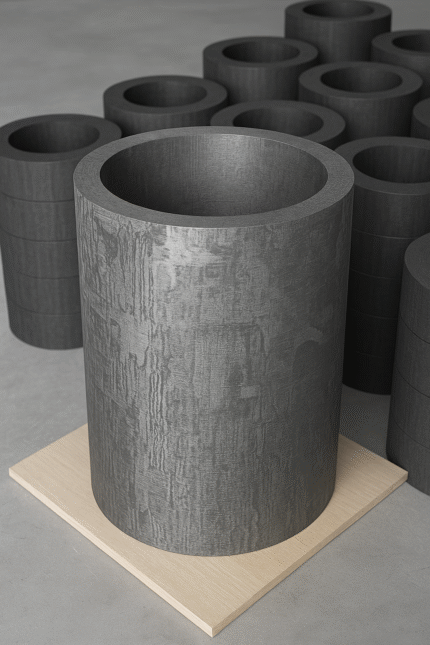

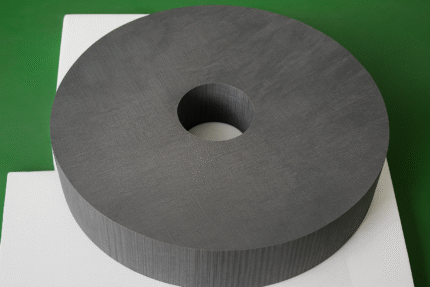

- Graphite Crucible

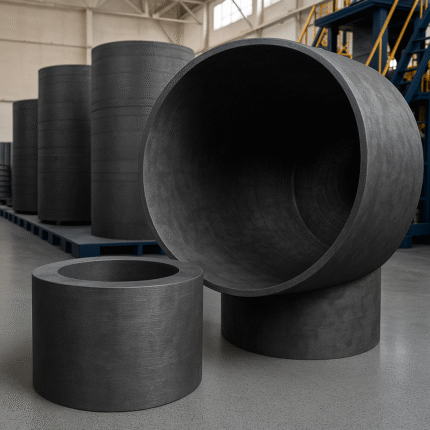

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

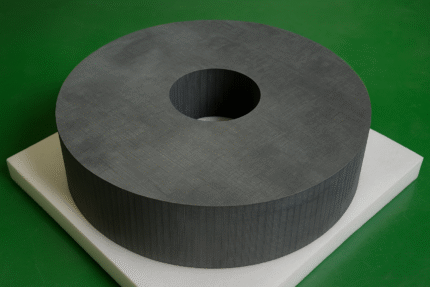

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

Carbon-Carbon Composite Screws & Studs

Discover high-strength carbon-carbon composite screws and studs by BZNCarbon. Designed for ultra-high temperature and vacuum environments with unmatched durability and reliability

Category: C-C Composites

Tag: Carbon-Carbon Composite Screws & Studs

Description

BZNCarbon manufactures precision-engineered carbon-carbon composite screws, studs, and fastening elements ideal for extreme thermal and mechanical environments. These fasteners are fabricated using advanced C/C materials—including 2.5D, 3D, and 4D fiber architectures—providing excellent strength-to-weight ratios and prolonged service life in high-stress applications.

Standard production density ranges between 1.7–1.9 g/cm³, and customized formulations are available upon request. Whether you’re building aerospace assemblies or high-temperature furnaces, our C/C fasteners deliver exceptional reliability where traditional materials fail.

What Are Carbon-Carbon Composite Fasteners?

C/C screws and studs are lightweight, thermally stable components manufactured from carbon fiber reinforced carbon matrix composites. Compared to metal fasteners, these offer superior thermal shock resistance, zero magnetic interference, and corrosion immunity, making them ideal for specialized industrial environments.

Applications

Aerospace: Fastening components in rocket nozzles, thermal shields, and satellite structures

Semiconductor and Solar: Secure elements in CVD reactors and crystal growing furnaces

Metallurgy and Sintering: Used in high-temperature hot pressing, sintering dies, or tooling fixtures

Medical Devices: Applied in high-purity environments where metallic contamination is unacceptable

Research Laboratories: Securement in nuclear reactors and plasma chambers

Electric Vehicles: Lightweight structural reinforcement in next-gen battery systems

Technical Specifications

| Property | Unit | Value (2.5D Reference) |

|---|---|---|

| Bulk Density | g/cm³ | ≥ 1.7 |

| Carbon Content | % | ≥ 99 |

| Tensile Strength | MPa | 40–60 |

| Tensile Modulus | GPa | 25–30 |

| Bending Strength (XYZ) | MPa | 80–110 |

| Compressive Strength (XYZ) | MPa | 90–130 (up to 260) |

| Shear Strength | MPa | 50–60 |

| Interlaminar Shear Strength | MPa | > 12 |

| Linear Expansion Coefficient | 10⁻⁶/K | 0.5–1.3 |

| Thermal Conductivity | W/m·K | 30–50 |

| Electrical Resistivity | µΩ·m | 15–30 |

| Processing Temperature | °C | > 2000 |

| Ash Content | ppm | ≤ 100 |

| Metal Impurity Content | ppm | ≤ 50 |

Other grades available based on 3D and 4D configurations.

Advantages of BZNCarbon C/C Screws & Studs

Ultra-High Temperature Stability: Performance sustained beyond 2000°C

Minimal Thermal Expansion: Retains structural integrity during thermal cycling

High Strength & Lightweight: Stronger than graphite, lighter than metal

Electrically Conductive: Ideal for electro-thermal assemblies

Non-Magnetic & Corrosion Resistant: Reliable in harsh chemical or magnetic environments

Low Outgassing: Suitable for vacuum and space applications

Customization & Support

BZNCarbon offers custom dimensions and threading options, including:

Metric and imperial threading

Studs with dual threading or anchor ends

Socket head cap screws

Bolts with head design per drawing or CAD

Our engineers work closely with you to ensure dimensional accuracy, tolerances, and fiber orientation meet your application’s unique needs.