- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

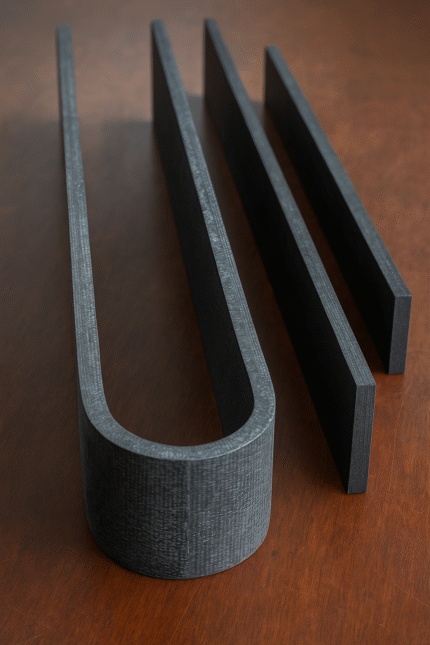

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

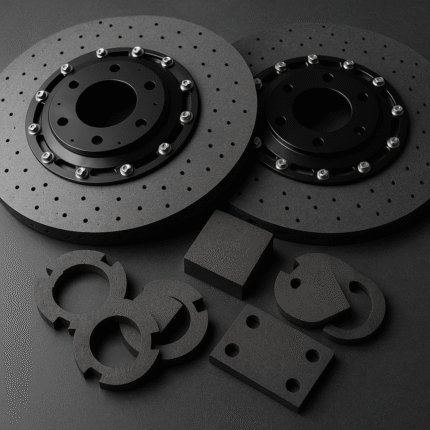

- Carbon Carbon Composite Racing Brake Discs and Pads

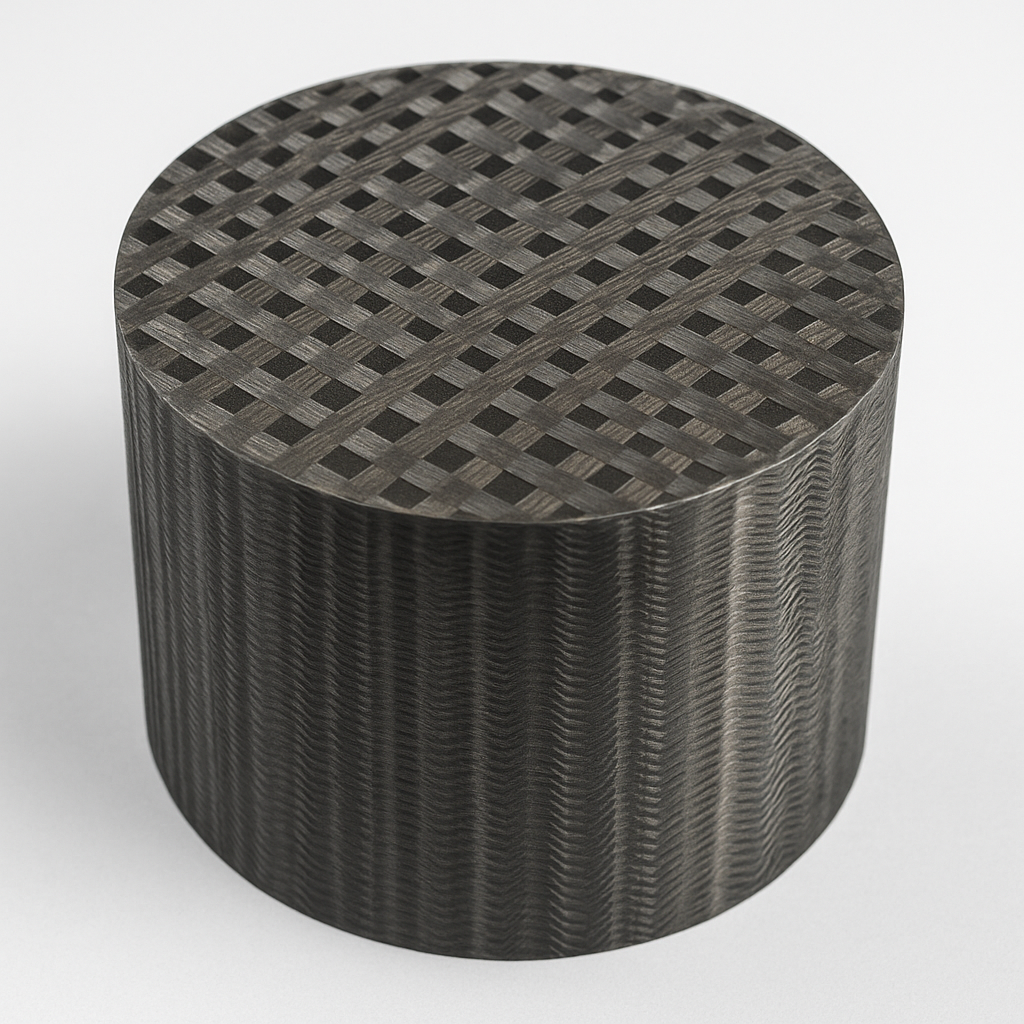

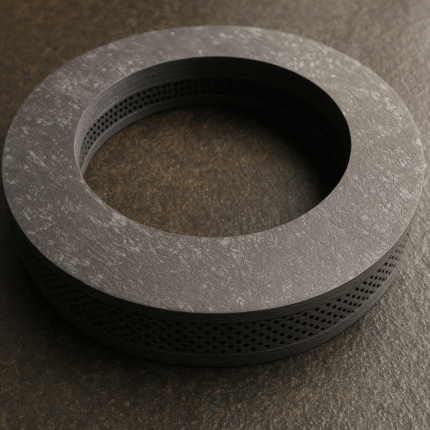

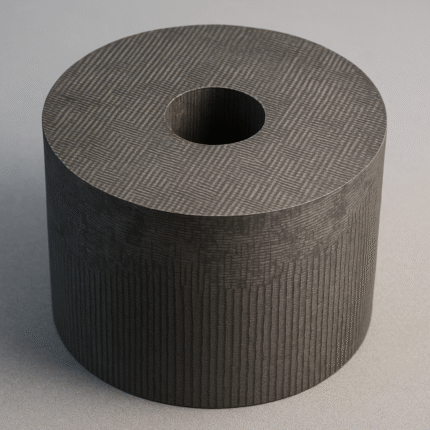

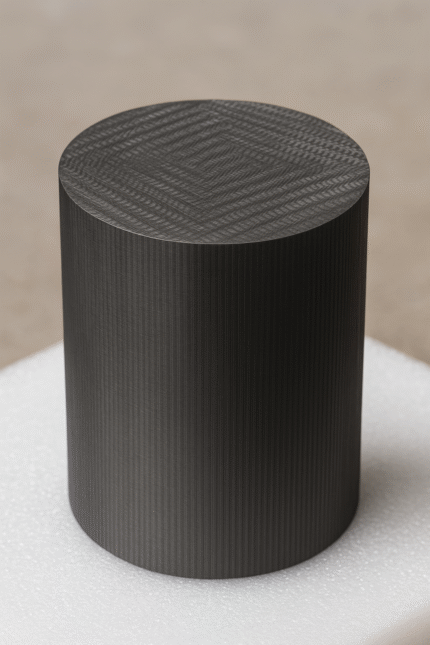

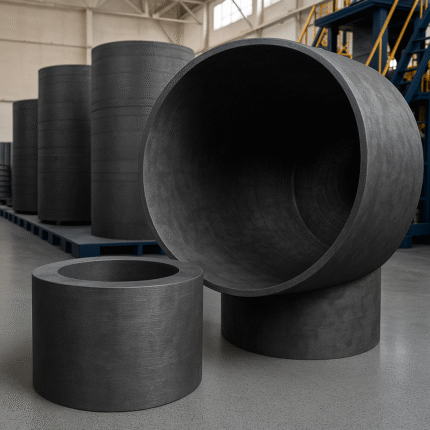

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

Carbon Carbon Composite Rods, Tubes, and Pipes

Discover high-strength, heat-resistant carbon carbon composite rods, tubes, and pipes by BZN Carbon. Ideal for aerospace, industrial, and high-temperature applications.

Description

BZN Carbon offers precision-engineered carbon carbon composite rods, tubes, and pipes, manufactured with consistent quality and customized to your specifications. Available in 2D, 2.5D, 3D, and 4D fiber structures, our C/C components are ideal for applications that demand extreme strength, thermal resistance, and durability under high-stress environments.

Material Options and Density

2D composite: 1.4 – 1.6 g/cm³

2.5D composite: 1.5 – 1.85 g/cm³

3D composite: 1.6 – 1.90 g/cm³

4D composite: 1.7 – 1.95 g/cm³

Tailored formulations and custom sizes are available upon request.

What Are Carbon Carbon Composite Rods and Tubes?

Carbon carbon composites (C/C) are advanced materials reinforced with carbon fibers embedded in a carbon matrix. After high-temperature processing, they achieve extremely high carbon content (>99%) and exhibit superior structural integrity even at elevated temperatures exceeding 2000–2500°C.

Key Features and Benefits

Ultra-High Thermal Resistance: Maintains mechanical strength at temperatures up to 2500°C in inert or vacuum environments.

Outstanding Corrosion Resistance: Resilient to chemical exposure, including acids, alkalis, and salts.

Low Density, High Strength: Excellent strength-to-weight ratio, making them ideal for aerospace and industrial uses.

Superior Thermal Shock Performance: Withstands rapid temperature changes without deformation or failure.

Custom Design Capabilities: Manufactured to exact specifications, including diameter, length, wall thickness, and fiber orientation.

Longevity & Cost Efficiency: Extended lifespan and lower maintenance needs compared to conventional materials like graphite or metal.

Applications

Carbon carbon composite rods and tubes are widely used across industries that demand extreme performance materials:

High-temperature furnaces and kilns

Aerospace thermal shielding systems

Industrial heating equipment

Semiconductor and photovoltaic manufacturing

Lightweight structural components

Rocket propulsion and defense systems

Automotive racing (heat-resistant frameworks and chassis elements)

Testing & Quality Assurance

All BZN Carbon components are available with advanced quality control services, including X-Ray inspection, structural integrity analysis, and mechanical testing, upon request.

Why Choose BZN Carbon?

At BZN Carbon, we combine advanced composite manufacturing technology with deep technical expertise to deliver tailored carbon carbon solutions. Whether you’re developing next-generation aerospace assemblies or upgrading thermal systems, our rods and tubes provide the mechanical strength, thermal reliability, and design flexibility your application demands.