- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

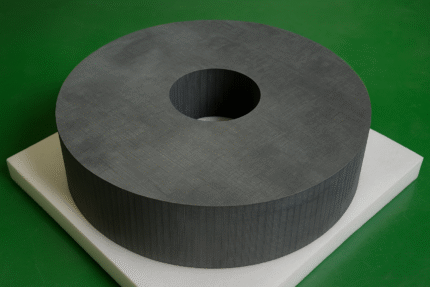

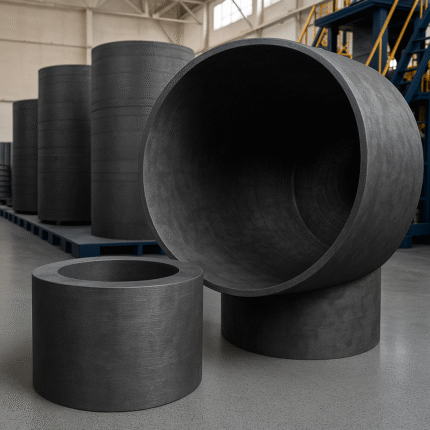

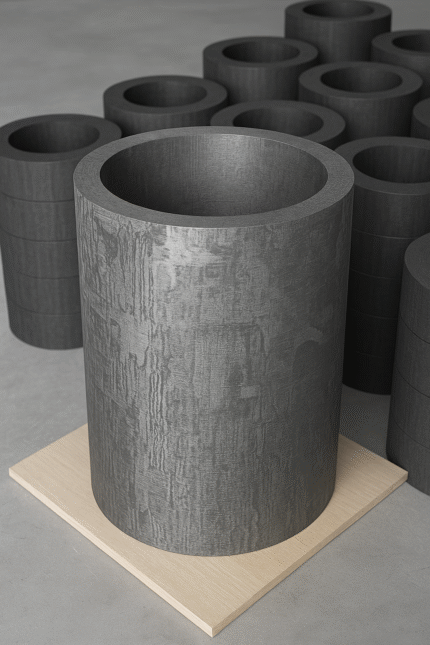

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

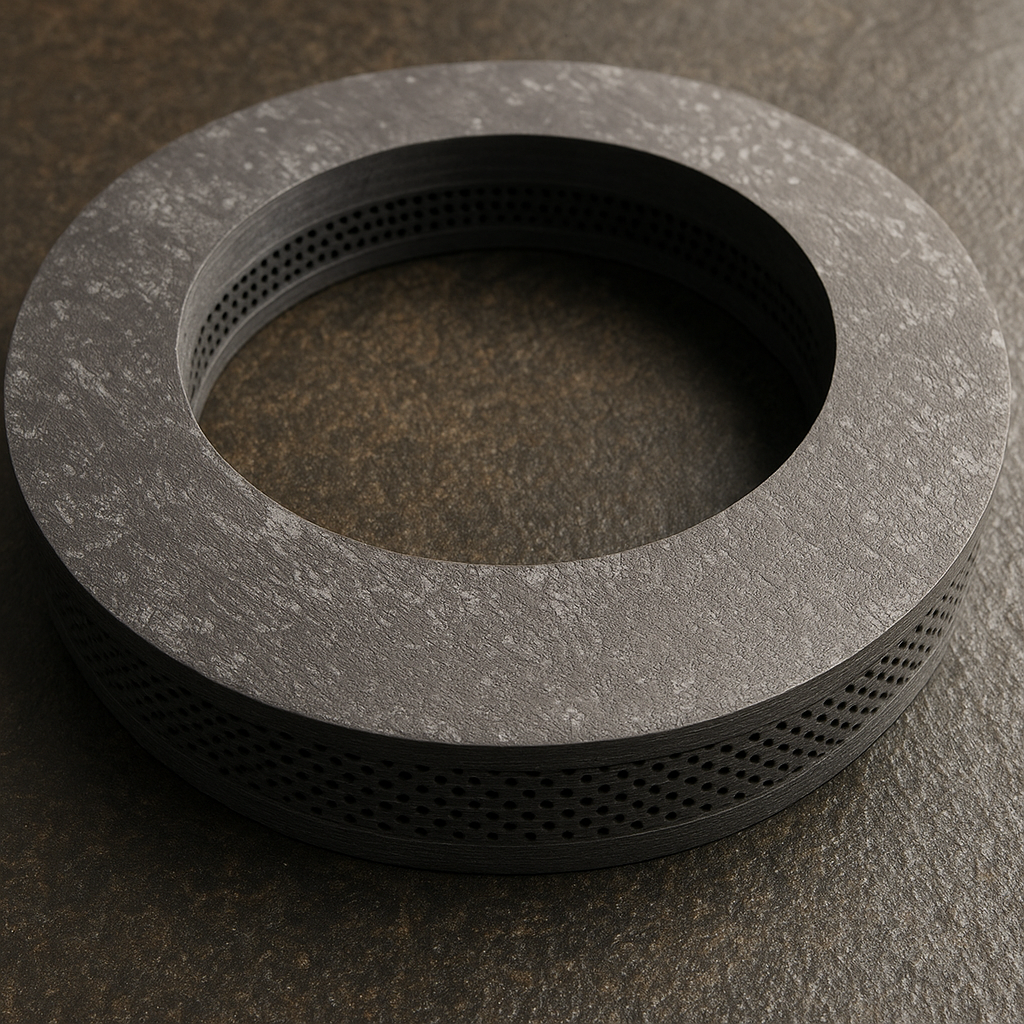

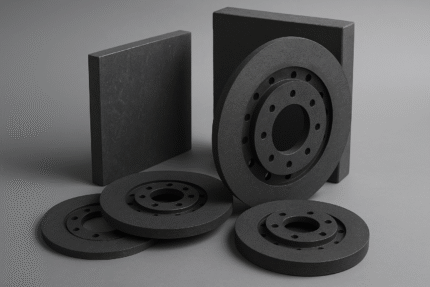

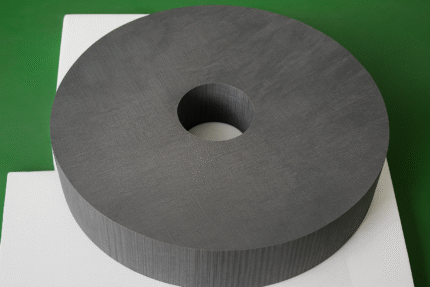

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

Carbon Carbon Composite Racing Brake Discs and Pads

Explore BZN Carbon’s lightweight and heat-resistant carbon composite racing brake discs and pads. Ideal for motorsport and high-performance vehicles. Custom specs available.

Description

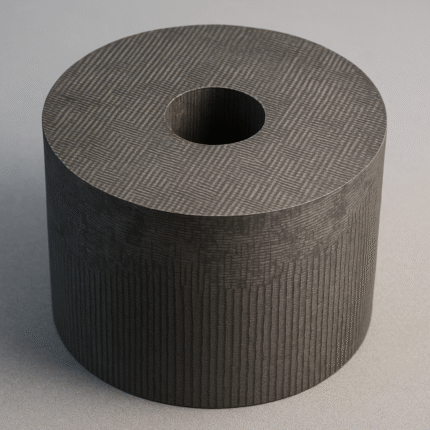

BZN Carbon designs and manufactures high-performance carbon-carbon composite brake discs and pads specifically engineered for motorsport and high-performance automotive applications. Our C/C racing brakes offer exceptional thermal stability, lightweight construction, and long-term reliability under extreme braking conditions. We offer fully customized production according to customer specifications, with 2.5D and 3D fiber structures.

Material Options & Density

2.5D composite: 1.6–1.8 g/cm³

3D composite: 1.5–1.85 g/cm³

Other configurations are available upon request or based on provided samples.

Key Properties of BZN Carbon Racing Brake Components

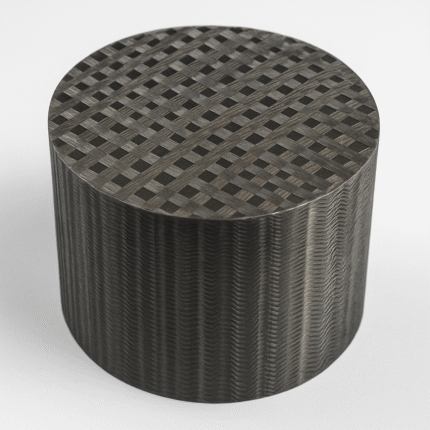

Carbon-carbon composite materials are favored for their unique combination of high strength, thermal resistance, and low weight. After undergoing high-temperature treatments, these materials exceed 99% carbon content, making them ideal for extreme environments.

Material Advantages

Thermal Resistance:

Capable of maintaining structural integrity at temperatures up to 2500°C, with outstanding resistance to thermal shock and ablation.Lightweight Design:

Significantly lower density than metal alternatives reduces the vehicle’s unsprung mass, improving responsiveness and performance.Wear Resistance:

Excellent resistance to mechanical wear and tear during high-friction braking cycles.Chemical Stability:

Resistant to acids, alkalis, and salt environments — suitable for both track and off-road conditions.Longevity & Safety:

Carbon-carbon composites extend service life and reduce the frequency of replacements, resulting in greater cost-efficiency and improved safety margins.

Applications

Professional motorsport (Formula racing, endurance racing, rally)

High-performance sports cars

Custom motorsport-grade brake systems

Any application requiring ultra-high temperature and friction stability

Customization

BZN Carbon can produce brake discs, rotors, and pads in a wide range of shapes, sizes, and densities according to detailed technical drawings or physical samples. Whether you’re building custom racing prototypes or seeking an OEM supply partner, we ensure consistent material quality and tailored performance.