- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

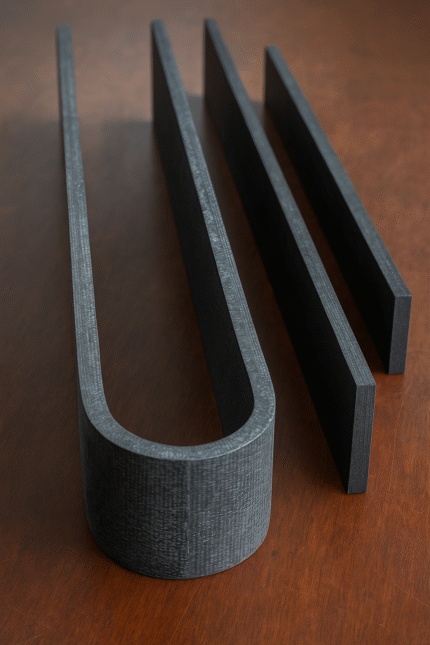

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

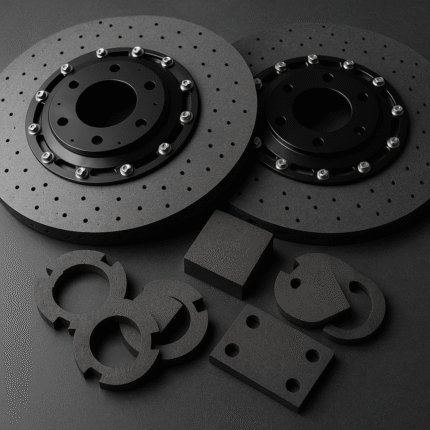

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

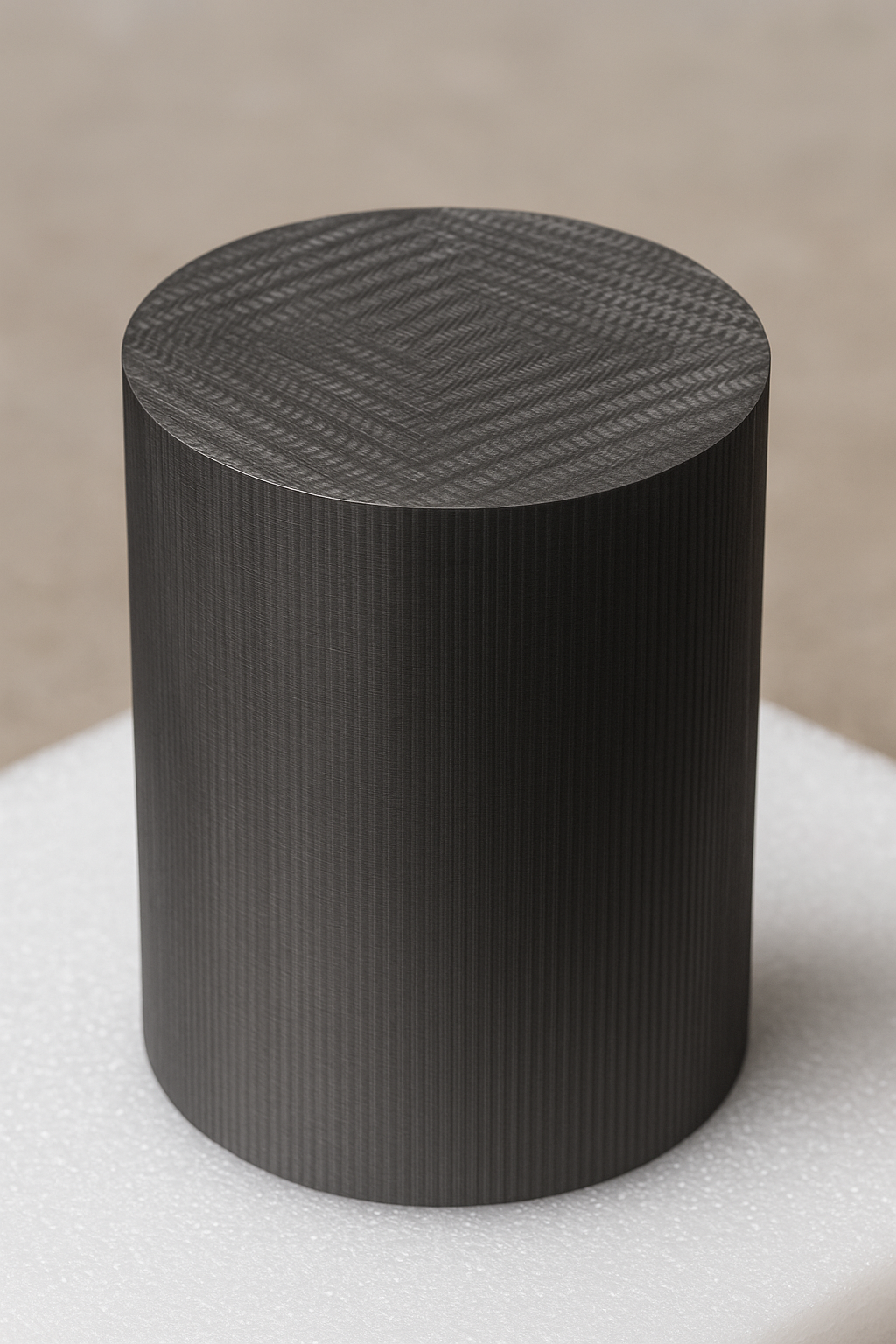

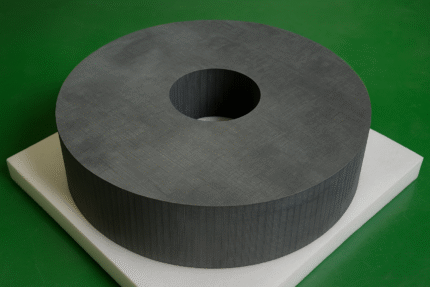

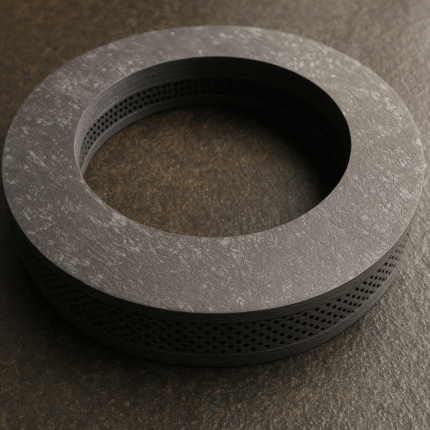

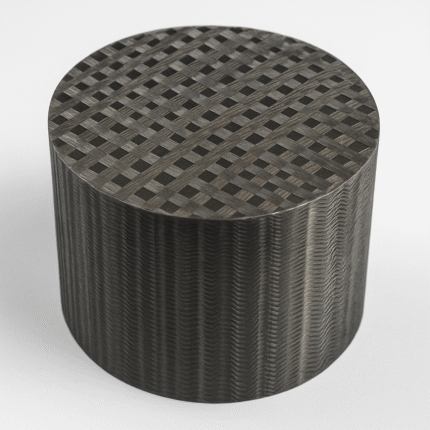

Carbon Carbon Composite Plates

Discover high-strength, heat-resistant carbon carbon composite rods, tubes, and pipes by BZN Carbon. Ideal for aerospace, industrial, and high-temperature applications.

Category: C-C Composites

Tag: Carbon Carbon Composite Plates

Description

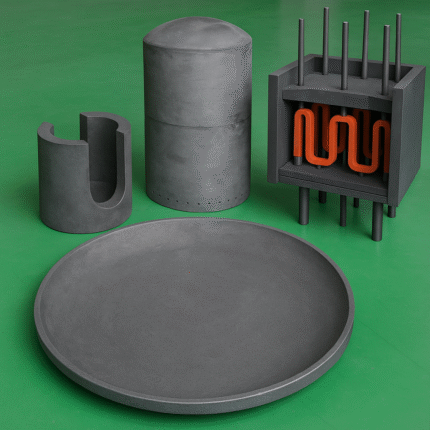

BZN Carbon specializes in the production of high-quality carbon carbon composite plates, designed for demanding industrial applications requiring exceptional thermal and mechanical performance. Our C/C composite plates are engineered using advanced fiber architecture—including 2D, 2.5D, 3D, and 4D reinforcements—to ensure optimized strength, dimensional stability, and service life at extreme temperatures.

We offer custom manufacturing based on client drawings and application requirements, including a variety of size and density combinations. Standard size options range from 10 mm to 600 mm in width/length, with thicknesses from 5 mm to 60 mm. Special dimensions and profiles can be tailored on request.

What Are Carbon Carbon Composite Plates?

Carbon carbon (C/C) composite plates are engineered materials formed by reinforcing carbon or graphite matrices with carbon fibers or fabrics. These composites are produced through a high-temperature process involving resin or pitch infiltration followed by carbonization and optional graphitization. The result is a lightweight yet ultra-strong plate capable of operating in harsh, high-temperature environments.

Key Features and Advantages

Exceptional Thermal Resistance: Capable of withstanding continuous use at temperatures exceeding 2500°C in inert or vacuum environments.

Lightweight with High Strength: Lower density compared to metal alloys, yet excellent flexural and compressive strength.

Superior Thermal Shock Resistance: Withstands rapid temperature changes without cracking or deformation.

Excellent Chemical Inertness: Resists corrosion from acids, alkalis, and salts; suitable for high-purity environments.

Customizable Structure and Density: Manufactured with different weave types and densities based on the application.

Standard Material Densities

| Structure | Density (g/cm³) |

|---|---|

| 2D | 1.4–1.6 |

| 2.5D | 1.5–1.8 |

| 3D | 1.6–1.95 |

| 4D | 1.7–1.95 |

Technical Properties of Carbon Composite Plates (Typical Values)

| Property | Unit | Value Range |

|---|---|---|

| Bulk Density | g/cm³ | 1.4 – 1.95 |

| Carbon Content | % | ≥ 99 |

| Tensile Strength | MPa | 40 – 60 |

| Bending Strength | MPa | 80 – 110 |

| Compressive Strength | MPa | 90 – 120 |

| Thermal Conductivity | W/m·K | 30 – 50 |

| Processing Temperature | °C | > 2000 |

| Ash Content | ppm | ≤ 100 |

| Specific Resistance | μΩ·m | 15 – 30 |

Typical Applications

Semiconductor & Solar Industry: Silicon wafer processing, thermal insulation, and crucible support plates.

Aerospace and Aviation: Thermal protection systems, structural panels, and brake heat shields.

Metallurgy & Foundry: High-temperature furnace liners, load-bearing trays, and insulation barriers.

Medical Equipment: Sterilization trays and components for thermal cycling environments.

Advanced Manufacturing: Graphite-replacement components for composite molding and tooling.

Why Choose BZN Carbon?

At BZN Carbon, we combine advanced engineering expertise with customizable manufacturing capabilities to deliver carbon carbon composite plates that meet your precise application standards. Whether you require a high-density 4D composite or a lightweight 2D configuration, we ensure consistent quality, fast turnaround, and technical support from concept to delivery.

Custom shapes, sizes, and fiber orientations available upon request. X-RAY inspection and other testing services are also provided.