- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

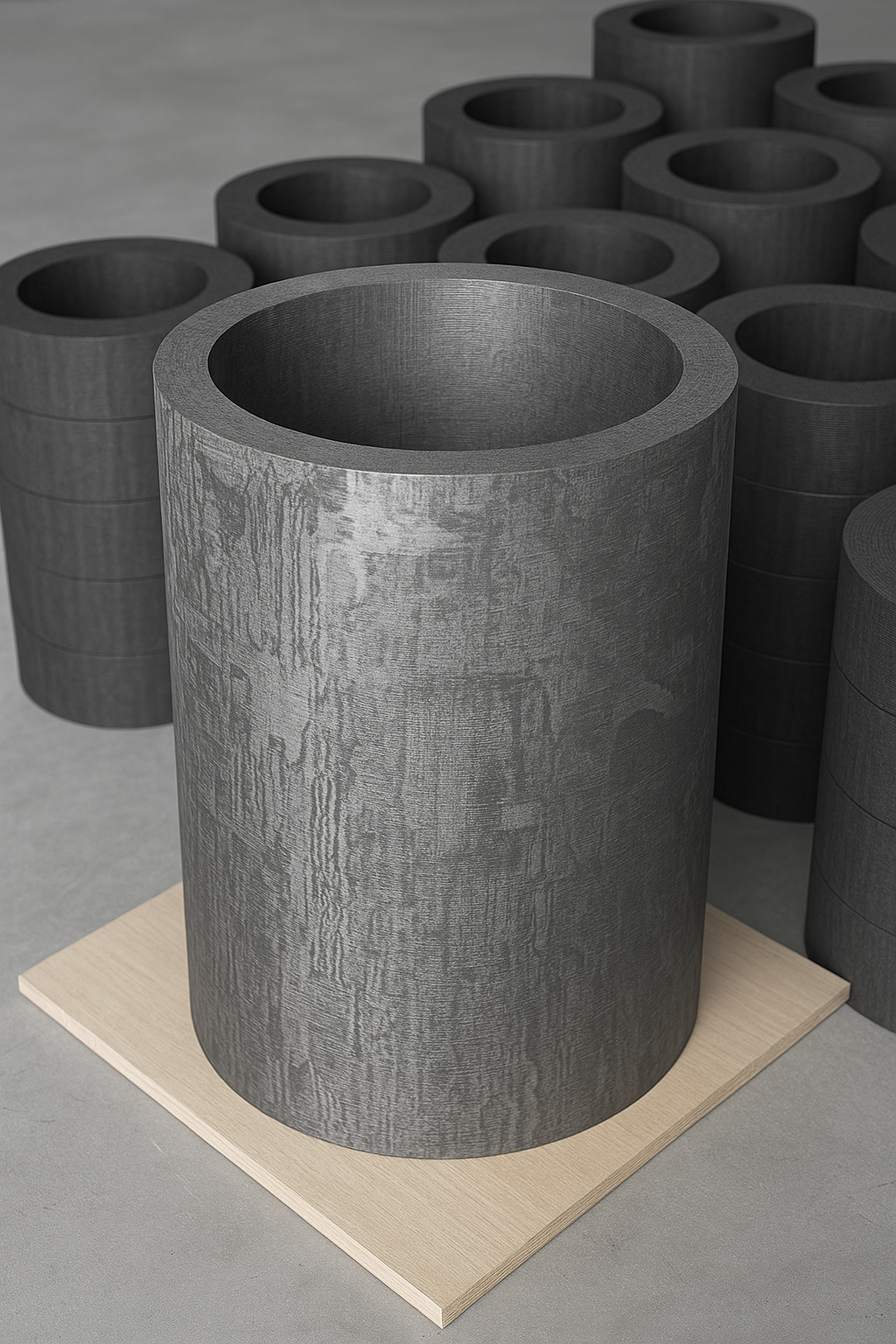

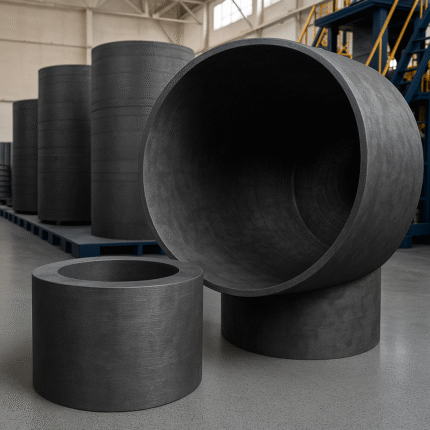

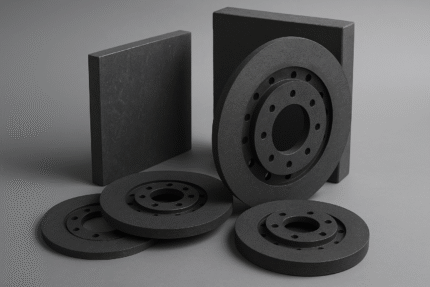

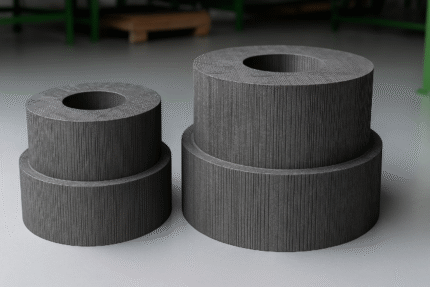

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

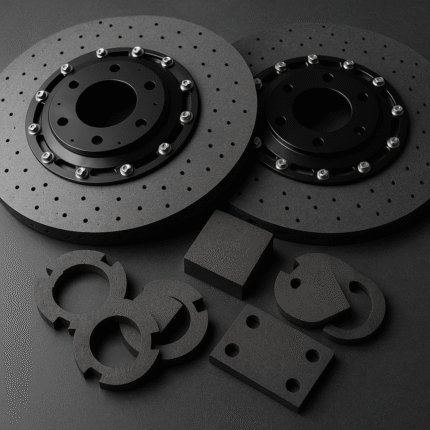

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

Carbon-Carbon Composite Moulds

BZNCarbon offers custom-engineered carbon-carbon composite moulds designed for aerospace, industrial, and high-temperature tooling. Superior thermal resistance and extended service life.

Category: C-C Composites

Tag: Carbon-Carbon Composite Moulds

Description

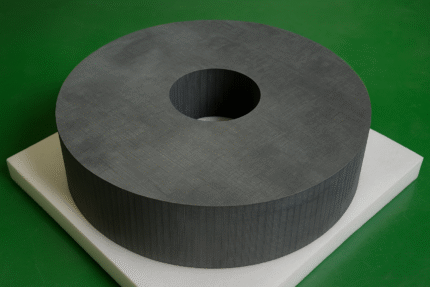

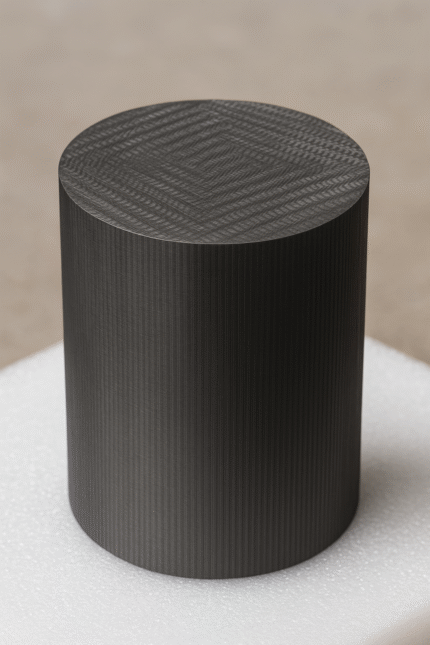

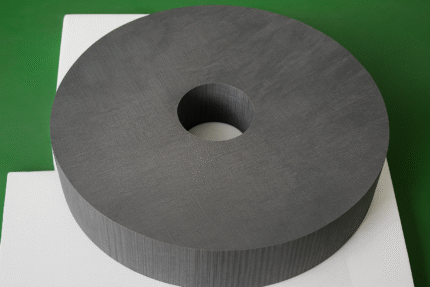

BZNCarbon specializes in the development and production of carbon-carbon composite moulds designed to operate under extreme conditions. These moulds are built using advanced fiber structures—2.5D, 3D, or 4D—with densities ranging from 1.5 to 1.9 g/cm³, depending on the specific performance and application requirements. Compared to conventional graphite moulds, our C/C moulds deliver enhanced durability, reduced thermal deformation, and longer operational life.

Whether you require intricate tooling for aerospace parts or high-strength moulds for furnace forming, BZNCarbon’s customized approach ensures optimal results across a variety of applications.

What Are Carbon-Carbon Moulds?

Carbon-carbon composite moulds are manufactured by reinforcing carbon fibers in multiple orientations and impregnating them with a carbon matrix. After high-temperature processing above 2000°C, the result is a lightweight, ultra-high-strength material that retains mechanical and thermal stability in harsh thermal environments.

These moulds offer significant advantages over graphite moulds, including superior flexural strength, lower oxidation rates (with protective treatment), and greater resistance to thermal cycling.

Key Applications

Aerospace forming tools

Precision pressing dies for sintering and hot-press applications

Vacuum and induction furnace moulds

Semiconductor and medical-grade component forming

Automotive ceramic or metal injection moulding (MIM/CIM) tooling

Glass, crystal, or sapphire shaping systems

Technical Specifications

| Property | Value |

|---|---|

| Bulk Density | ≥ 1.70 g/cm³ |

| Flexural Strength | ≥ 100 MPa |

| Ash Content | ≤ 50 ppm |

| Carbon Content | ≥ 99.99% |

| CTE (Coefficient of Expansion) | ≤ 3 ×10⁻⁶/K |

| Electrical Resistance | 30–50 μΩ·cm |

| Max Operating Temperature | Up to 2300°C (in inert) |

All properties may be customized based on fibre structure and customer requirements.

Advantages of BZNCarbon C/C Moulds

High Thermal Endurance: Maintains shape and strength in extreme heat

Long Service Life: Reduces tooling replacement frequency

Customizable Geometry: Produced from customer CAD files or physical samples

Dimensional Stability: Maintains accuracy even under high stress

Excellent Conductivity: Useful for systems requiring thermal uniformity

Minimal Ash and Contamination: Cleanroom and semiconductor-ready

Oxidation Protection & Surface Coating

While carbon-carbon materials can begin to oxidize in oxygen-rich environments above 400°C, BZNCarbon offers multiple oxidation resistance strategies, including:

Matrix densification and surface passivation

Application of protective coatings to isolate C/C material from oxygen exposure

Optional surface treatments adapted to furnace atmosphere and use-case

Our oxidation protection technologies significantly prolong the life of moulds used in aerobic high-temperature applications.

Design & Manufacturing Capabilities

2.5D, 3D, and 4D fibre architecture

Press and die systems

Cylindrical or conical moulds

Multi-part assembly tooling

Quick-turn prototyping and batch production available