- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

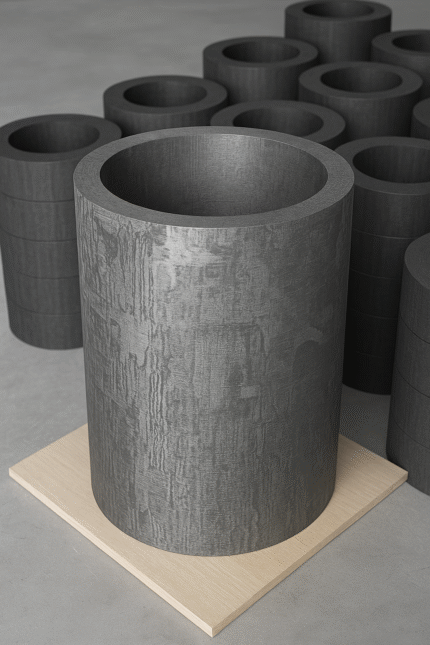

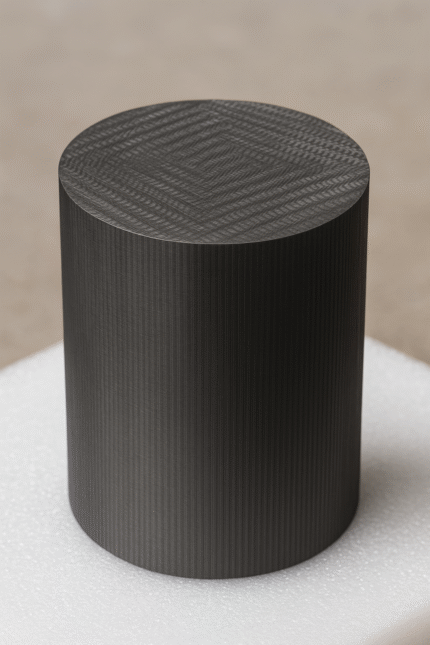

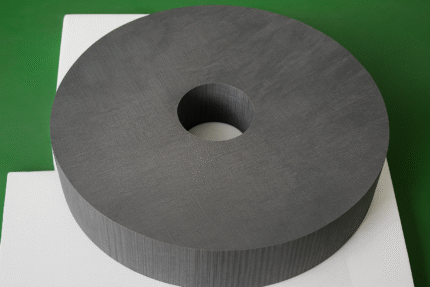

Carbon-Carbon Composite Insulation Barrels & Blankets

Explore premium carbon-carbon composite insulation barrels and blankets from BZNCarbon, designed for polycrystalline and monocrystalline silicon furnaces. High thermal resistance and lightweight durability.

Description

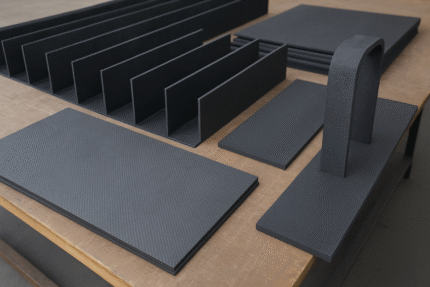

BZNCarbon’s carbon-carbon composite insulation barrels and thermal blankets are engineered to provide superior heat containment, dimensional stability, and structural integrity within high-temperature processing environments. Designed primarily for solar-grade silicon production furnaces, these components are manufactured using multi-directional fiber reinforcements in 2D, 2.5D, or 3D formats to meet the highest thermal performance standards.

We offer a wide range of insulation solutions for Czochralski (CZ) single crystal and polycrystalline silicon ingot furnaces, ensuring energy efficiency, structural longevity, and optimal thermal uniformity.

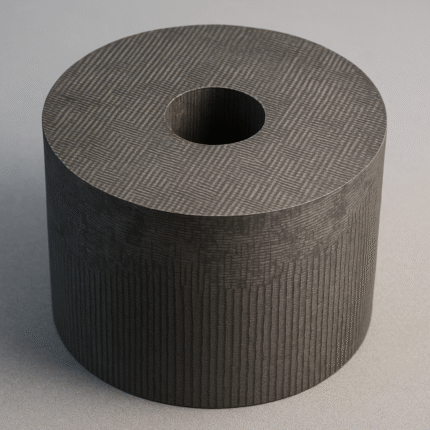

What Are Carbon-Carbon Composite Insulation Barrels?

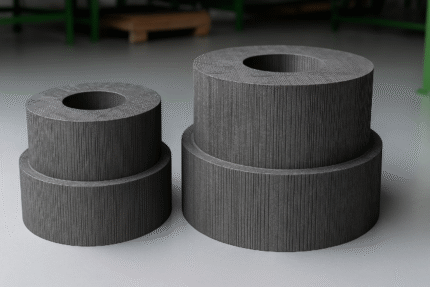

Carbon-carbon insulation barrels are precision-formed cylindrical structures composed of carbon fiber reinforcement and carbon matrix. These components are highly resistant to thermal degradation and maintain mechanical integrity at operating temperatures of up to 2800°C in inert gas and up to 2000°C in vacuum.

Compared to traditional graphite insulation, C/C composite insulation offers enhanced strength, reduced mass, and significantly longer service life, resulting in lower long-term operational costs.

Common Applications

For Polysilicon Hydrogenation Furnaces:

Inner and outer insulation barrels

U-type heaters

Insulation boards

For Polycrystalline Ingot Furnaces:

Crucible shielding covers

Base protection plates

Lining insulation boards

For Czochralski Single Crystal Furnaces:

Crucible carriers

Heat guide tubes

Inner and outer insulation barrels

End caps and thermal shields

Graphite-free high-purity covers

Material Options & Density

| Structure Type | Typical Density (g/cm³) |

|---|---|

| 2D | 1.4–1.6 |

| 2.5D | 1.5–1.8 |

| Custom | On request |

Each configuration can be customized in shape, thickness, and mechanical tolerance depending on application-specific requirements.

Advantages of BZNCarbon C/C Insulation

Thermal Resistance: Stable at extreme temperatures (2000–2800°C depending on atmosphere)

Mechanical Strength: 3x stronger than traditional graphite insulation

Low Mass: Reduces thermal lag and mechanical load in furnace structures

Superior Longevity: Minimizes material fatigue and replacement frequency

Excellent Thermal Shock Resistance: Maintains shape and properties under rapid heating/cooling cycles

Clean & Low Ash: Maintains ultra-low contamination for solar-grade processes

Custom Engineering: Designed to fit customer-specific furnace layouts or retrofit needs

Design & Manufacturing Capabilities

Round, conical, or stepped barrel structures

Slotted or open-ended designs

Integration with graphite-free or metal-free systems

Modular insulation panel systems available

OEM part replication supported by CAD-based manufacturing