- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

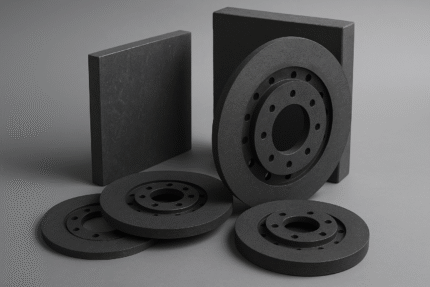

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

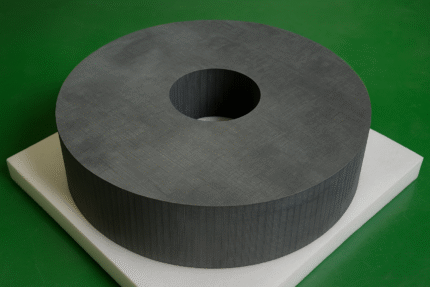

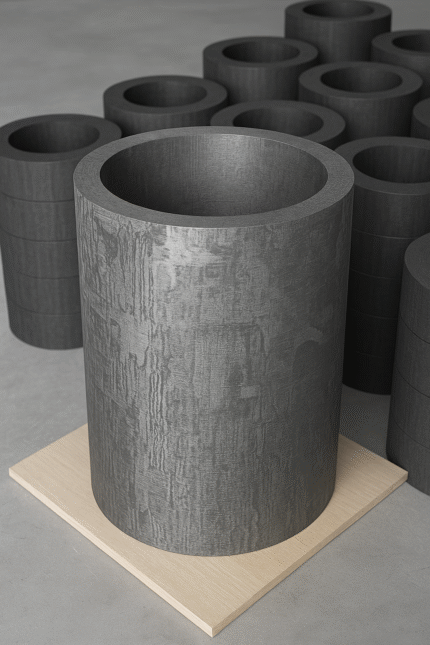

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

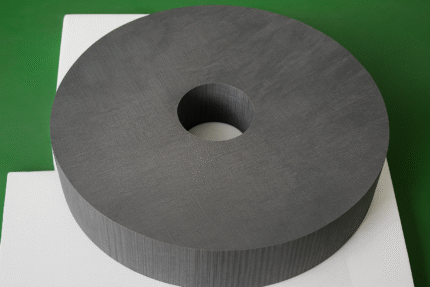

- Carbon Carbon Composite Blocks

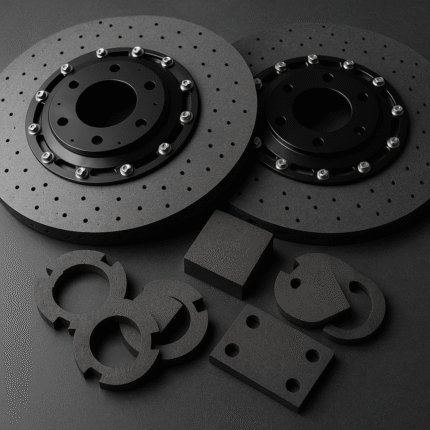

- Carbon Carbon Composite Racing Brake Discs and Pads

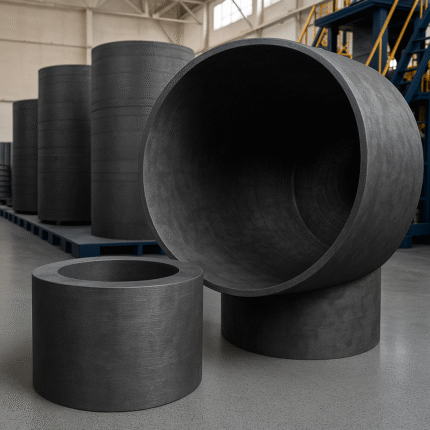

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

Carbon-Carbon Composite Heaters & Heating Elements

Discover lightweight, long-life carbon-carbon composite heating elements from BZNCarbon. Designed for high-temperature furnaces including polycrystalline silicon and vacuum systems.

Category: C-C Composites

Tag: Carbon-Carbon Composite Heaters & Heating Elements

Description

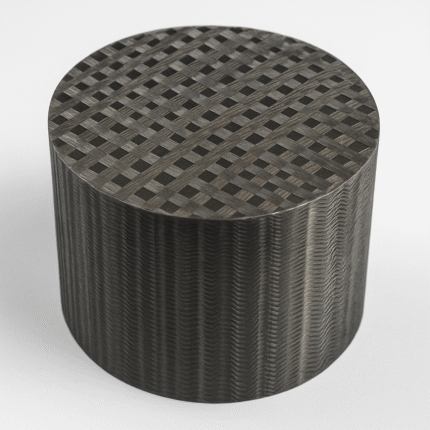

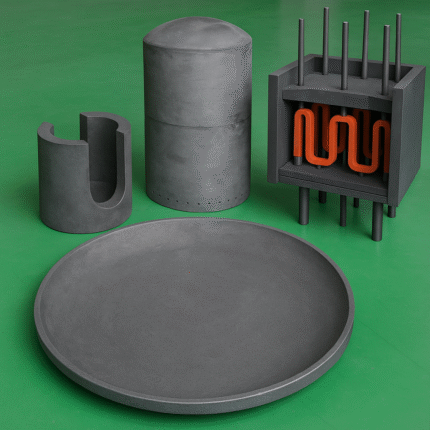

BZNCarbon’s carbon-carbon composite heaters and heating elements are engineered for high-efficiency thermal applications, including polycrystalline silicon furnaces and other advanced processing equipment. These components are crafted from 2D, 2.5D, or 3D carbon composite structures and deliver unmatched stability, long operational life, and exceptional resistance to thermal shock.

With bulk densities ranging from 1.4 to 1.8 g/cm³, we customize every part based on customer drawings and operational demands, using precision machining and high-temperature processing (>2200°C) to ensure reliable, reproducible performance.

What Are Carbon Composite Heaters?

Carbon-carbon composite heaters are formed by reinforcing carbon fibers in 2D or multidirectional patterns, then densifying the structure through graphitization. This creates lightweight components that maintain their shape and electrical/thermal performance even under extreme temperatures.

Due to the nature of carbon-carbon materials, these heaters exhibit low thermal expansion, fast heating response, and excellent oxidation resistance in protected atmospheres.

Common Applications

Polycrystalline Silicon Production Furnaces

Vacuum and Sintering Furnaces

High-Temperature Reactors

Crystal Growth Chambers (Czochralski & Bridgman)

Semiconductor Wafer Processing Equipment

Solar Cell Manufacturing Lines

Laboratory Thermal Equipment and R&D Furnaces

Technical Specifications (2D Structure, Typical Density: 1.4–1.5 g/cm³)

| Property | Unit | Value |

|---|---|---|

| Bulk Density | g/cm³ | 1.4–1.5 |

| Tensile Strength | MPa | 40–60 |

| Tensile Modulus | GPa | 25–30 |

| Bending Strength | MPa | 80–110 |

| Compressive Strength | MPa | 90–120 |

| Thermal Conductivity | W/m·K | 30–50 |

| Processing Temp. | °C | >2200 |

| Ash Content | ppm | ≤200 |

Higher density 2.5D and 3D options available upon request. Tighter tolerances available for semiconductor-grade systems.

Key Benefits

Stable Resistance Heating even under extended cycling

Low Mass for faster ramp-up and cooldown times

Excellent Thermal Shock Resistance

Minimal Deformation at high temperatures

Longer Service Life than traditional graphite or metal heaters

Reduced Contamination Risk due to ultra-low ash content

Custom Shapes and Sizes manufactured to customer CAD files

Design & Customization

BZNCarbon can produce carbon composite heaters in a wide range of formats, including:

Flat plates

Cylindrical tubes

L-shaped or U-shaped bars

Slotted or grooved elements

Multilayer panel heaters for distributed thermal control

Simply provide your design or application parameters, and our engineering team will match the best C/C composite grade and shape.