- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

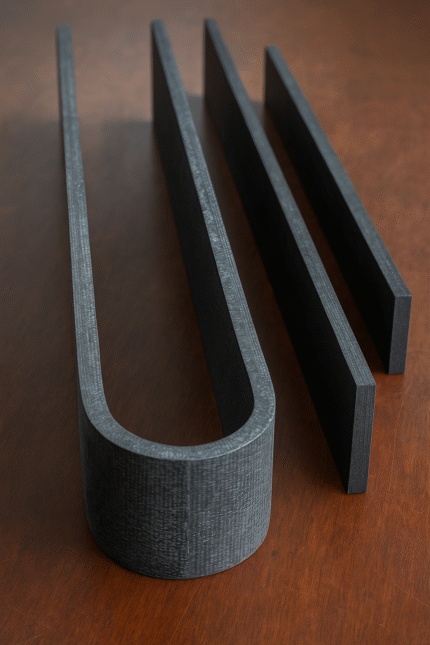

- Carbon Carbon Composite U & L Profiles

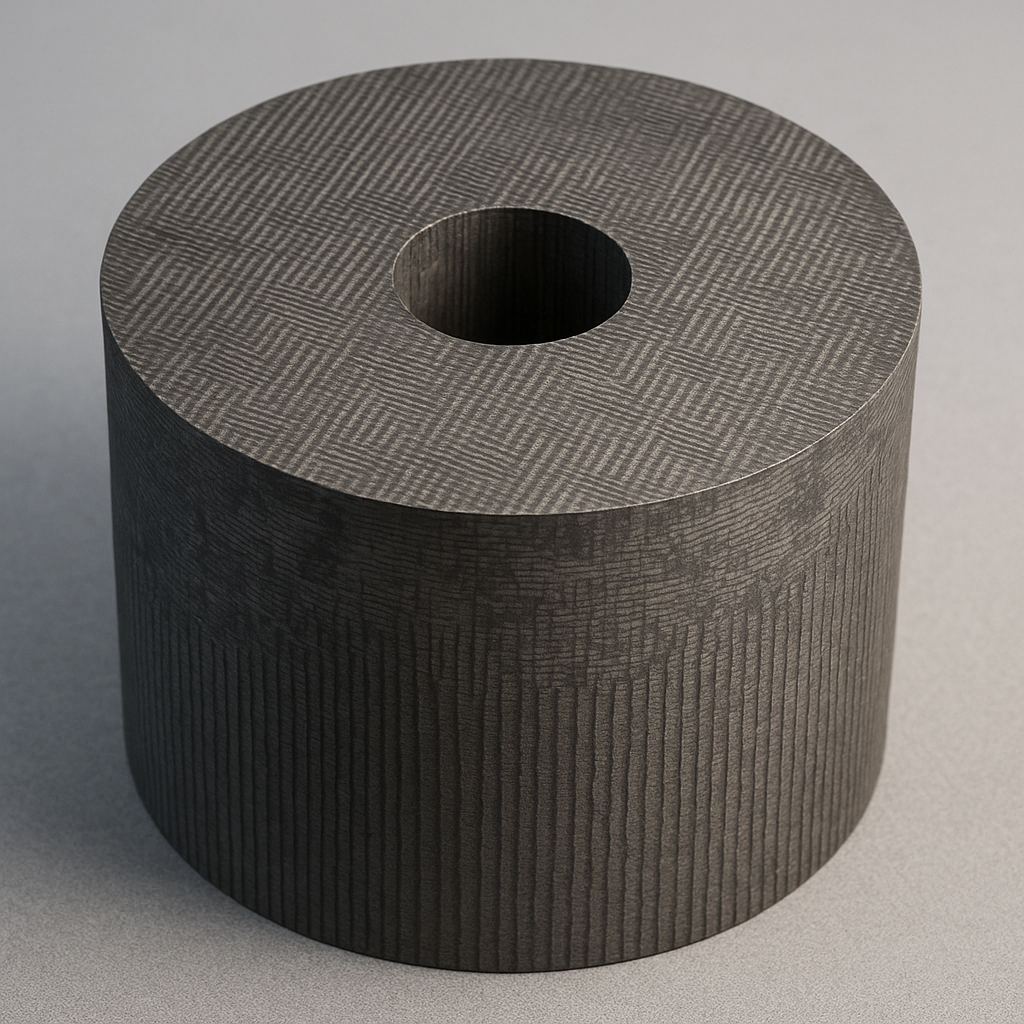

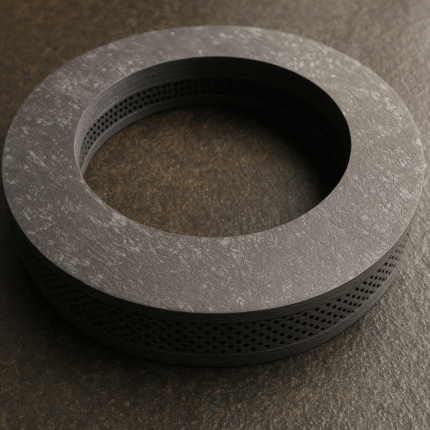

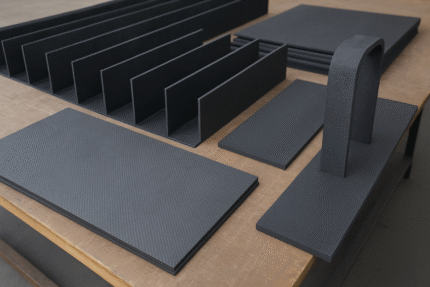

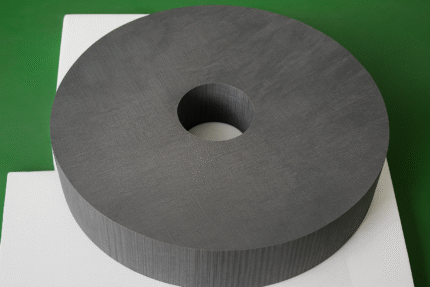

- Carbon Carbon Composite Blocks

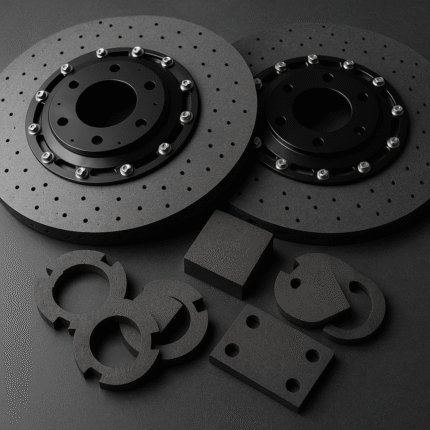

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

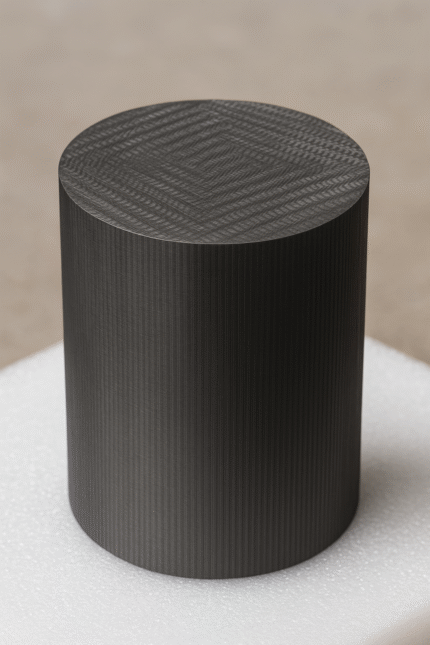

Carbon Carbon Composite Blocks

Discover high-strength, thermal-resistant carbon carbon composite blocks by BZN Carbon. Ideal for aerospace, semiconductor, and furnace applications. Custom shapes & densities available.

Category: C-C Composites

Tag: Carbon Carbon Composite Blocks

Description

BZN Carbon specializes in manufacturing high-quality carbon carbon composite blocks (C/C blocks) tailored to meet the demanding requirements of thermal and structural applications. These components are engineered using advanced 2D, 2.5D, 3D, and 4D carbon fiber architectures, ensuring optimal thermal stability, mechanical strength, and service life across extreme environments.

Product Overview

Carbon carbon composite blocks are fabricated from carbon fiber reinforced carbon matrix materials. They offer a unique combination of light weight, excellent thermal shock resistance, low thermal expansion, and outstanding performance at elevated temperatures. Compared to conventional graphite blocks, C/C blocks provide superior mechanical integrity and oxidation resistance in inert atmospheres.

Available Densities:

2D: 1.4–1.6 g/cm³

2.5D: 1.5–1.8 g/cm³

3D: 1.6–1.93 g/cm³

4D: 1.7–1.95 g/cm³

(Customized grades available upon request)

Shapes & Sizes:

Custom block sizes, shapes, and tolerances are available based on customer drawings or sample parts. We also offer precision machining and X-ray testing for structural integrity validation.

Applications

C/C composite blocks from BZN Carbon are widely used in:

High-temperature furnace linings and support structures

Monocrystalline and polycrystalline silicon production systems

Aerospace thermal shielding and ablative components

Semiconductor and solar-grade silicon purification equipment

Vacuum furnaces and hot pressing tooling

Nuclear and military-grade heat-resistant structures

Key Advantages

High Thermal Stability: Maintains structural performance up to 2500°C in inert or vacuum environments.

Outstanding Mechanical Properties: High strength-to-weight ratio and excellent resistance to wear, fatigue, and mechanical impact.

Thermal Shock Resistance: Ideal for rapid heating/cooling cycles in processing systems.

Lightweight & Corrosion Resistant: Significantly lighter than traditional refractory materials, with excellent resistance to chemical erosion.

Custom Design Flexibility: Complex 3D or 4D architecture options allow optimized performance for specific applications.

Typical Properties (2.5D Example)

| Item | Unit | 2.5D Value |

|---|---|---|

| Bulk Density | g/cm³ | 1.5 – 1.8 |

| Carbon Content | % | ≥99.9 |

| Tensile Strength | MPa | 40 – 60 |

| Flexural Strength | MPa | 80 – 110 |

| Compressive Strength | MPa | 90 – 130 |

| Thermal Conductivity | W/m·K | 30 – 50 |

| Linear Expansion Coefficient | 10⁻⁶/K | 0.5 – 1.3 |

| Processing Temperature | °C | >2000 |

| Ash Content | ppm | ≤100 |