- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

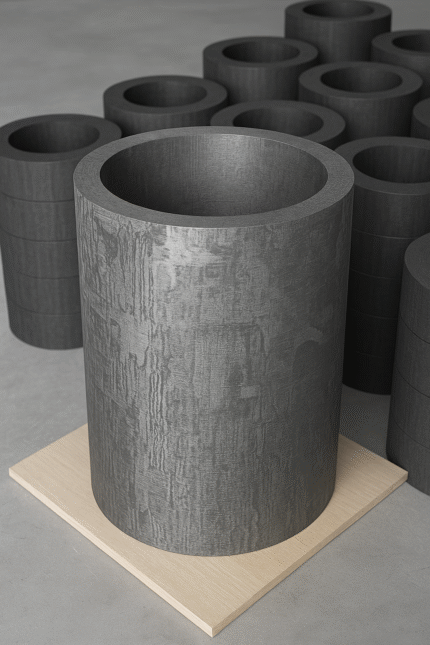

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

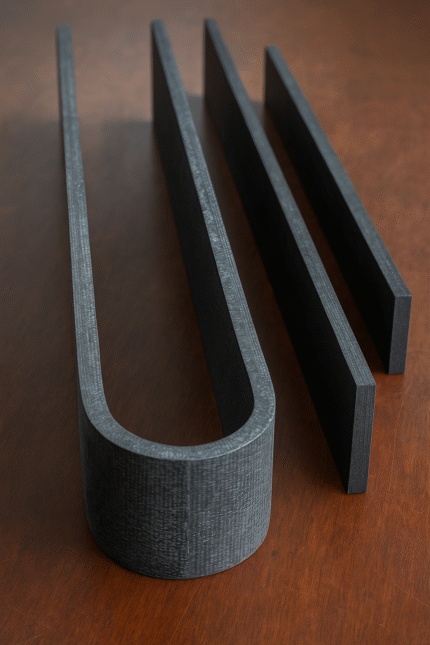

- Carbon Carbon Composite U & L Profiles

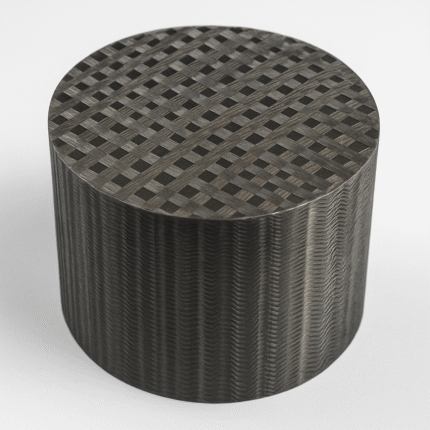

- Carbon Carbon Composite Blocks

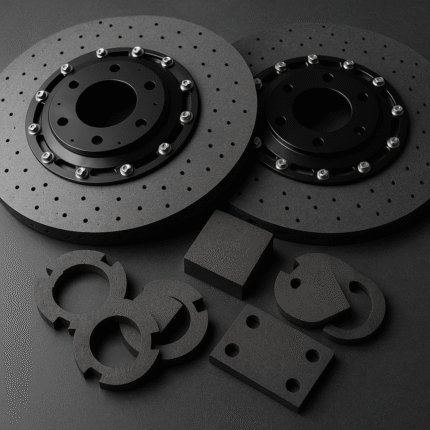

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

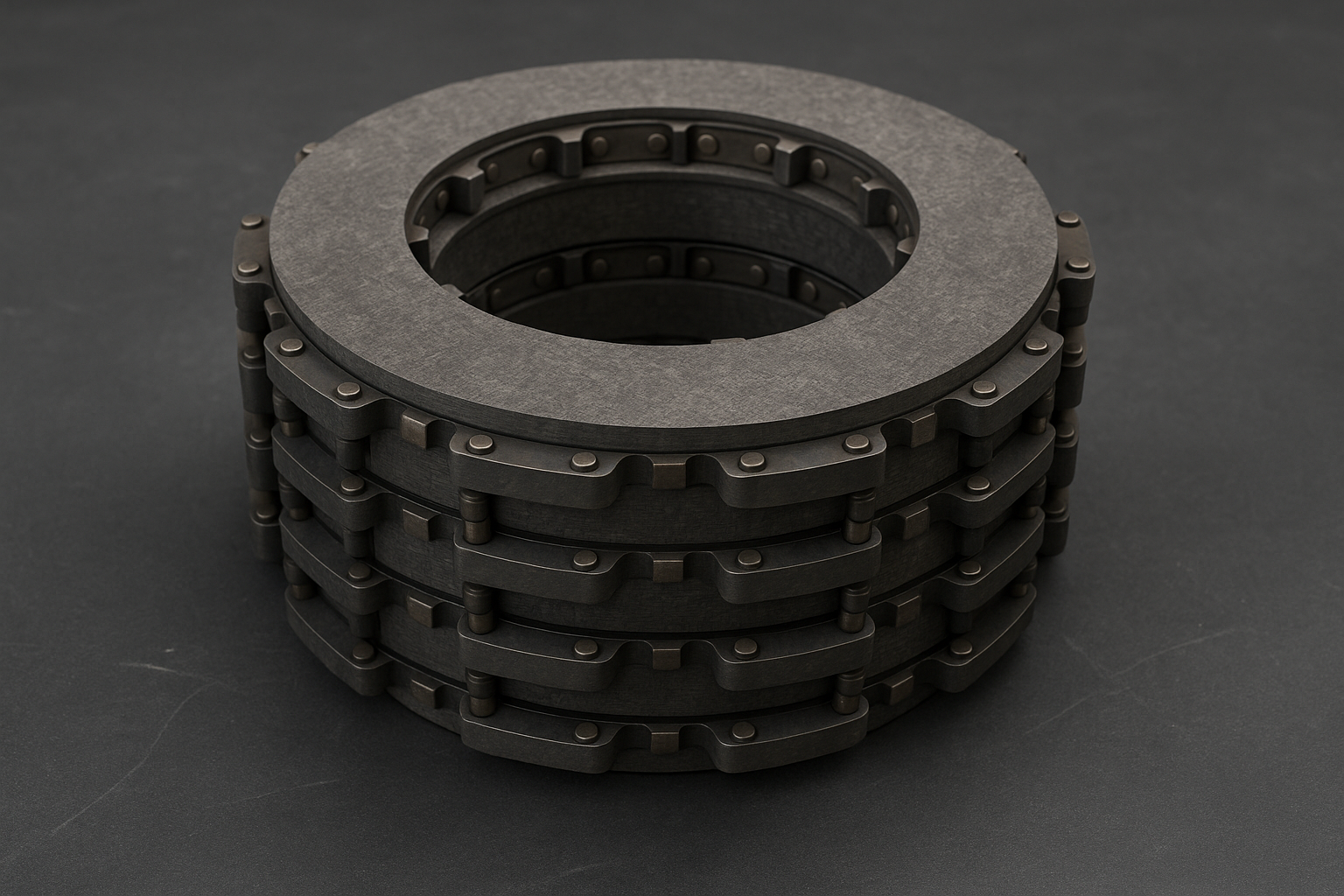

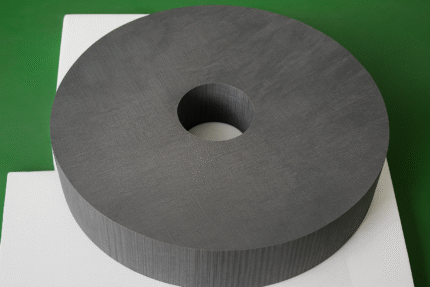

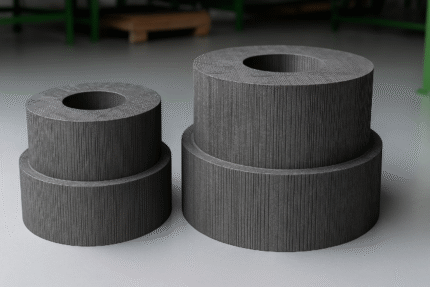

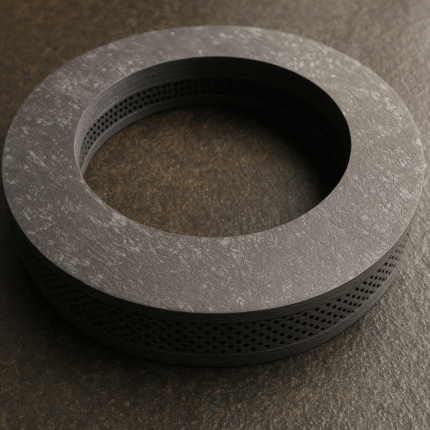

Carbon-Carbon Composite Aircraft Brake Discs

Explore BZNCarbon’s high-performance carbon-carbon composite aircraft brake discs engineered for commercial and defense aviation. Lightweight, durable, and highly thermally stable.

Category: C-C Composites

Tag: Carbon-Carbon Composite Aircraft Brake Discs

Description

BZNCarbon manufactures carbon-carbon composite brake discs for aircraft braking systems using proprietary 2.5D fiber-reinforced structures. These components are engineered to offer superior performance in high-load and high-temperature aviation environments. Our products are already in service across commercial aircraft fleets with proven reliability and durability.

Each brake disc is manufactured using advanced carbon fiber preforms, processed at temperatures exceeding 2000°C, and inspected using X-ray and non-destructive methods to ensure internal structural integrity. Custom geometries, densities, and profiles can be produced to meet individual aircraft models or retrofit requirements.

What Is a Carbon-Carbon Brake Disc?

Carbon-carbon brake discs are high-performance friction materials made from carbon fiber reinforcements within a carbon matrix. Unlike traditional metal discs, C/C brake components maintain mechanical strength and frictional performance at extreme temperatures without risk of warping, melting, or fading. They offer significant weight savings, extended wear life, and lower maintenance requirements.

Key Applications

Commercial jetliners (e.g. Boeing 757, Airbus A320, C919)

Military aircraft and unmanned aerial systems

High-speed aviation testing platforms

Civil air cargo carriers requiring low-maintenance braking systems

Advanced aerospace R&D projects

Technical Specifications

| Property | Unit | Value |

|---|---|---|

| Bulk Density | g/cm³ | ≥1.78 |

| Carbon Content | % | ≥99.99 |

| Bending Strength | MPa | 140 |

| Compressive Strength | MPa | ≥180 |

| Interlaminar Shear Strength | MPa | >15 |

| Thermal Conductivity | W/m·K | 20–80 |

| Dynamic Friction Coefficient | — | 0.24–0.42 (tunable) |

| Static Friction Coefficient (20.6 MPa) | — | ≥0.16 |

| Linear Wear (Inertial Platform) | µm/time/face | ≤1.5 |

| Processing Temperature | °C | >2000 |

| Ash Content | ppm | ≤100 |

| Metallic Ash Content | ppm | ≤50 |

Key Features and Advantages

Weight Reduction: Up to 40% lighter than steel, reducing aircraft weight and improving fuel efficiency

Thermal Stability: Maintains performance at extreme temperatures—no deformation, melting, or brake fade

Low Wear Rate: Only 25–50% of wear compared to conventional metallic brakes

Long Service Life: Supports up to 1000 cycles for military aircraft and 3000+ cycles for civil aviation

Repairable: Discs can be refurbished once they reach wear limits

Low Maintenance: Extended intervals between inspections and overhauls

Manufacturing & Quality Assurance

BZNCarbon is one of the few producers capable of manufacturing aviation-grade brake discs with complete vertical integration—from carbon fiber sourcing and preform shaping to final densification and testing. All products undergo:

High-temperature graphitization >2000°C

Non-destructive evaluation including X-ray scanning

Mechanical and thermal testing with traceable reports

Custom engineering based on CAD drawings or OEM specifications