- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

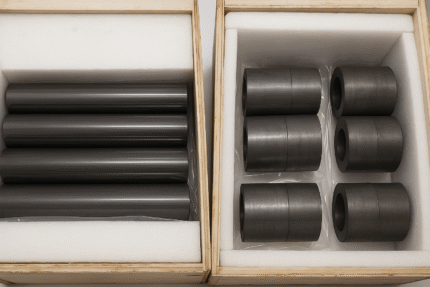

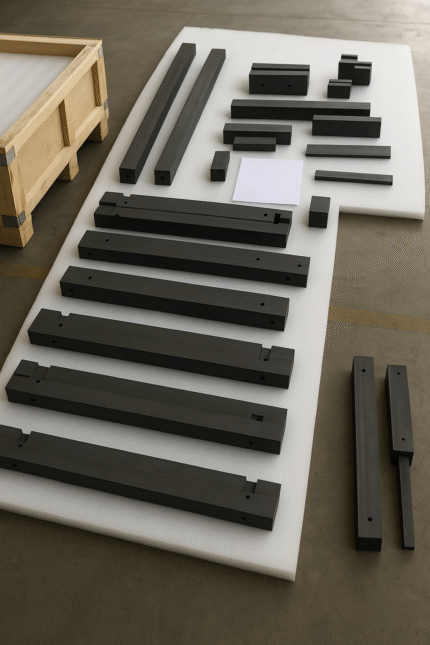

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

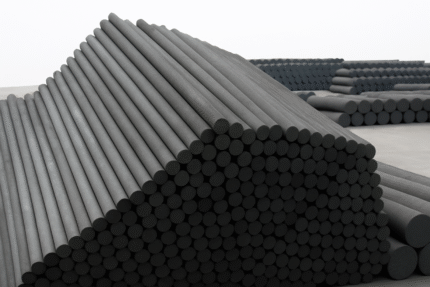

- Graphite Electrode

- Graphite Bipolar Plate

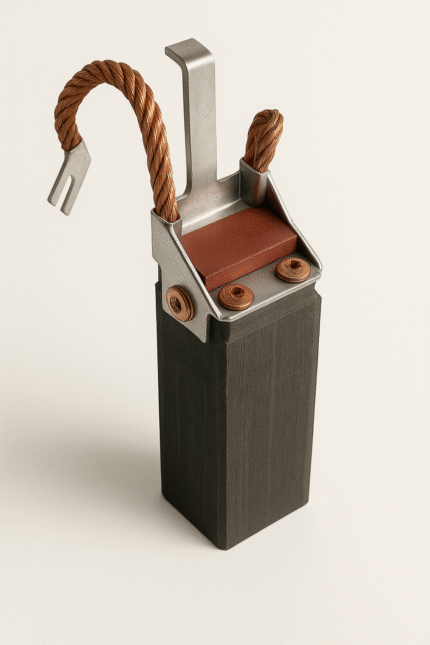

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

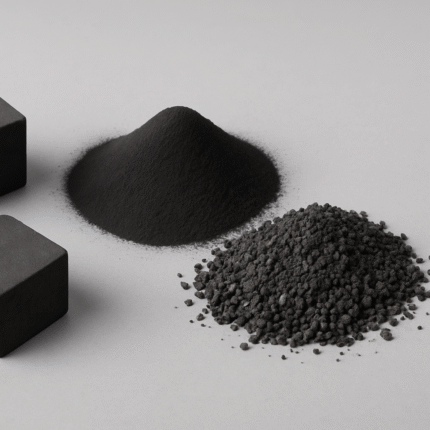

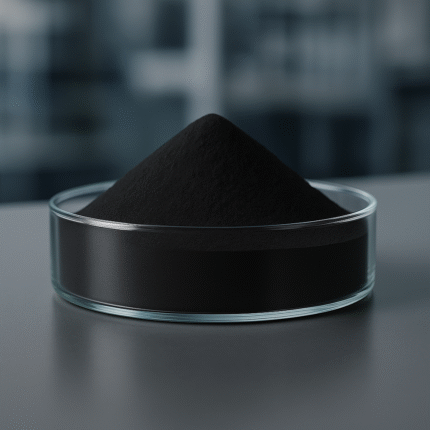

Calcined Petroleum Coke

150,00 €

BZNCarbon’s Calcined Petroleum Coke (CPC) is a premium-grade, high-carbon material obtained through the controlled thermal processing of Green Petroleum Coke (Raw Petroleum Coke – RPC). This transformation occurs in rotary kilns at temperatures between 1200°C and 1400°C, during which moisture, volatile matter, and impurities are eliminated—resulting in a highly pure, electrically conductive, and chemically stable carbon material.

Contact us for competitive pricing on orders exceeding 50 kg

Description

What is CPC and How is It Made?

CPC is produced by calcining green petroleum coke, a by-product of crude oil refining. After mechanical crushing and sizing, the RPC is introduced into a calcination furnace. The process enhances its density, purity, and conductivity, making it a valuable raw material for industries that require high-performance carbon additives or structural materials under high-temperature conditions.

Key Applications

BZNCarbon’s GRADE-A CPC is ideal for applications where low ash and sulfur levels are crucial to performance and product quality. It is widely used in:

Aluminum Industry: As an anode material in aluminum smelting via Hall-Héroult process.

Steel & Ferroalloy Production: Acts as a carbon additive and recarburizer in electric arc furnaces.

Titanium Dioxide Production: Used as a reducing agent during the chloride process.

Foundry Applications: Serves as an inoculant or carburizer for cast iron and ductile iron casting.

Graphite Electrode Manufacturing: Used in the production of synthetic graphite rods and blocks.

Its high thermal resistance, electrical conductivity, and structural integrity make it ideal for high-temperature processes in aggressive chemical or metallurgical environments.

Technical Specifications

| Characteristic | Specification |

|---|---|

| Moisture Content | 0.1% Max. |

| Ash Content | 0.5% Max. |

| Volatile Matter | 0.4% Max. |

| Fixed Carbon | 99% Min. |

| Real Density | 2.05 g/cm³ Min. |

| Sulphur Content | 1.0% Max. |

| Silicon (Si) | 0.05% Max. |

| Iron (Fe) | 0.04% Max. |

| Vanadium (V) | 0.03% Max. |

| Nickel (Ni) | 0.02% Max. |

Typical reference data. Custom specifications are available upon request.

Packaging & Supply Options

Available in jumbo bags, paper sacks, or bulk tanker deliveries

Custom particle size distribution options available (e.g. 0–1 mm, 1–5 mm, 5–15 mm)

Suitable for international and domestic logistics needs

Additional information

| Kilogram |

1kg ,5kg ,10kg ,50kg |

|---|

Related products

Select options

This product has multiple variants. The options may be chosen on the product page

Expanded Graphite Powder – High Conductivity Grade BZ-75

200,00 €

Select options

This product has multiple variants. The options may be chosen on the product page