- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

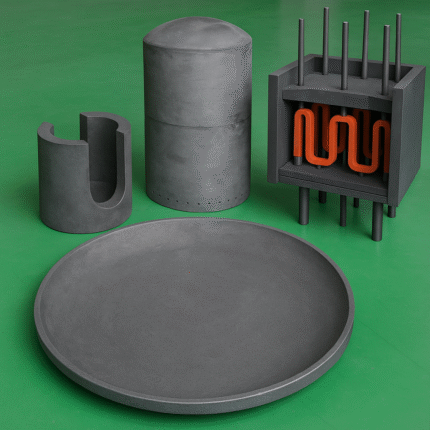

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

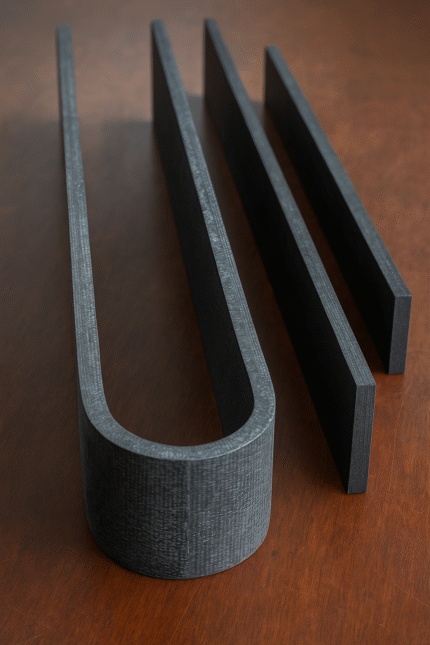

- Carbon Carbon Composite U & L Profiles

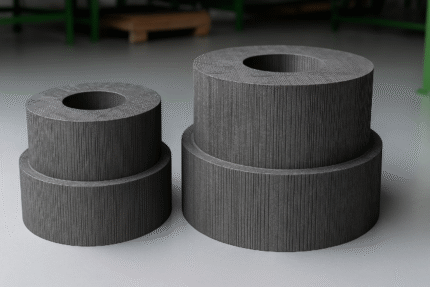

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

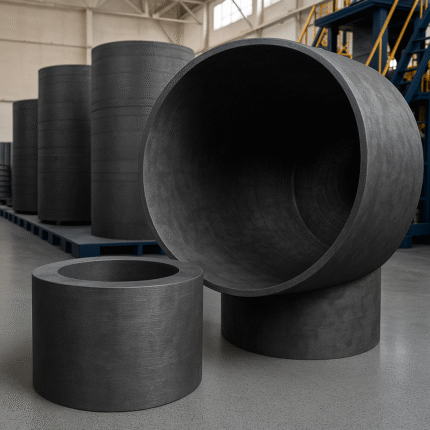

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

4D / 5D Carbon-Carbon Composite Materials

Explore BZNCarbon’s advanced 4D and 5D carbon-carbon composites. Engineered for aerospace, energy, and thermal applications requiring superior strength, density, and temperature resistance.

Category: C-C Composites

Tag: 4D / 5D Carbon-Carbon Composite Materials

Description

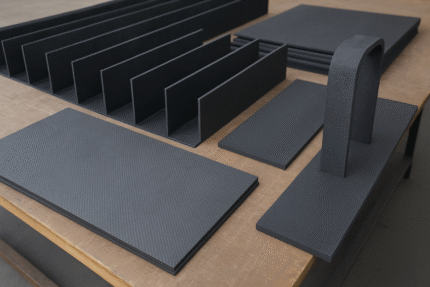

BZNCarbon’s 4D and 5D carbon-carbon composites are next-generation materials tailored for the most demanding thermal and structural environments. Unlike traditional 3D carbon-carbon materials, our 4D/5D composites incorporate additional fiber orientations within the plane, offering optimized load distribution and durability.

Manufactured using pitch-based or resin-based matrices and advanced CVI/CVD processes, these composites exhibit outstanding mechanical integrity, density control, and heat resistance. With customizable properties and formats, BZNCarbon’s high-density 4D/5D C/C composites are ideal for mission-critical systems across aerospace, defense, energy, and industrial sectors.

What Are 4D and 5D Carbon-Carbon Composites?

While all C/C materials are inherently three-dimensional (with fiber alignment in the X, Y, and Z axes), 4D and 5D structures introduce one or more additional fiber bundles within the planar directions—such as hoop, radial, or circumferential reinforcements. This enhances in-plane mechanical strength and thermal conductivity without compromising weight.

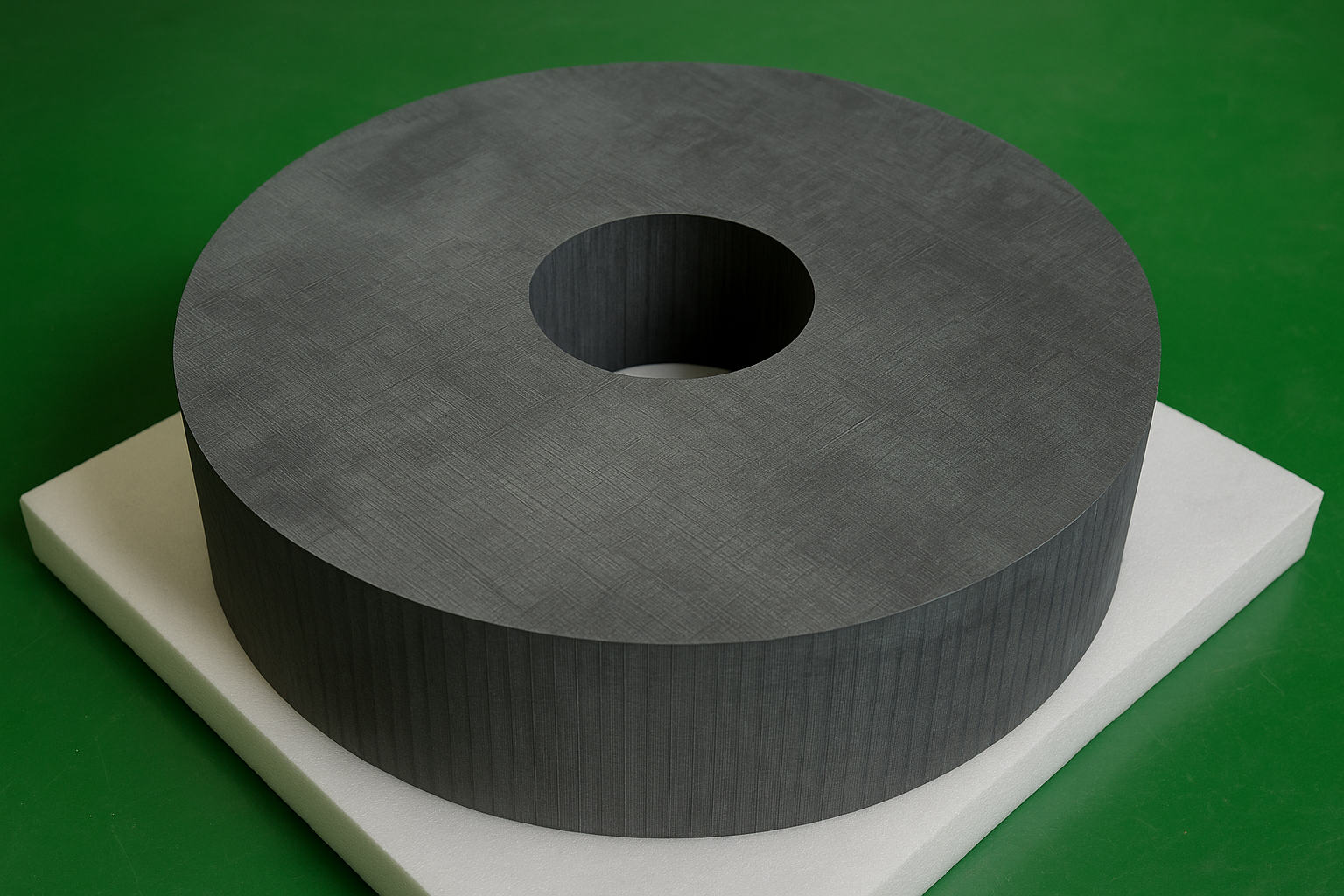

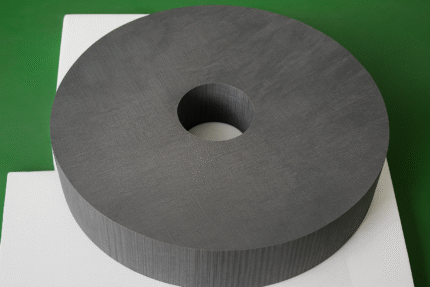

BZNCarbon can also provide polar-woven or hoop-based 4D composites, where reinforcement follows circular or radial patterns, commonly used in rotating systems or cylindrical thermal barriers.

We produce materials with bulk densities ranging from 1.5 to 1.95 g/cm³, and we are capable of reaching ≥1.90 g/cm³ with specialized isostatic and HIP equipment.

Applications

Aerospace structural components

Rocket motor insulators and throat linings

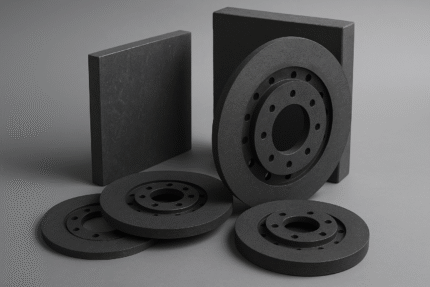

Brake pads and friction discs for defense or racing

High-temperature molds and tooling

Furnace supports, carriers, and lining systems

Nuclear shielding and containment fixtures

Thermal protection systems for re-entry vehicles

General Specifications (XYZ-based 4D Composites)

| Property | Direction | Requirement | Typical Result |

|---|---|---|---|

| Bulk Density | — | ≥ 1.85 g/cm³ | 1.868 g/cm³ |

| Fiber Configuration | — | 4D | 4D |

| Tensile Strength | X-Y / Z | ≥130 MPa / ≥70 MPa | 161 MPa / 76 MPa |

| Tensile Modulus | X-Y / Z | ≥50 GPa / ≥30 GPa | 59.1 GPa / 38 GPa |

| Flexural Strength | X-Y | ≥120 MPa | 142 MPa |

| Compressive Strength | X-Y / Z | ≥160 MPa / ≥220 MPa | 162 MPa / 274 MPa |

| Thermal Conductivity (900°C) | X-Y / Z | ≥40 / ≥20 W/m·K | 50 / 22 W/m·K |

| Thermal Expansion (1000°C) | X-Y / Z | 0.5–1 / 1–1.5 ×10⁻⁶/K | 0.55 / 1.16 ×10⁻⁶/K |

| Porosity | — | 3–5% | 4.3% |

| Specific Heat (RT–590°C) | X-Y / Z | Reported | 1.569×10³ / 1.620×10³ J/kg·K |

| X-ray Inspection | — | No defects | Passed |

Polar / Hoop-Woven 4D Composite Specifications

| Property | Value |

|---|---|

| Fiber Volume – Total | 40–45% |

| Fiber Volume – Hoop Direction | 45% ± 5 |

| Fiber Volume – Axial Direction | 36% ± 4 |

| Fiber Volume – Radial Direction | 19% ± 4 |

| Bulk Density | ≥ 1.90 g/cm³ |

| Tensile Strength (Hoop) | ≥ 100 MPa |

| Compressive Strength (Hoop) | ≥ 80 MPa |

| Compressive Strength (Axial) | ≥ 71 MPa |

| Thermal Conductivity (900°C) | ≥ 40 W/m·K (Hoop) / ≥ 22 (Axial) |

| Thermal Expansion | < 3.1 ×10⁻⁶ /°C |

| Open Porosity | < 5% |

| Carbon Content | ≥ 99.9% |

| Graphitization Temperature | ≥ 2500 °C |

Advantages

Ultra-high temperature capability (up to 3000°C+ in inert environments)

Highly customizable reinforcement patterns (3D/4D/5D/Hoop/Polar)

Superior resistance to thermal shock and chemical attack

Extended wear life in frictional and structural uses

Lightweight, rigid, and oxidation-resistant structure

Enhanced dimensional stability under dynamic loads