- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

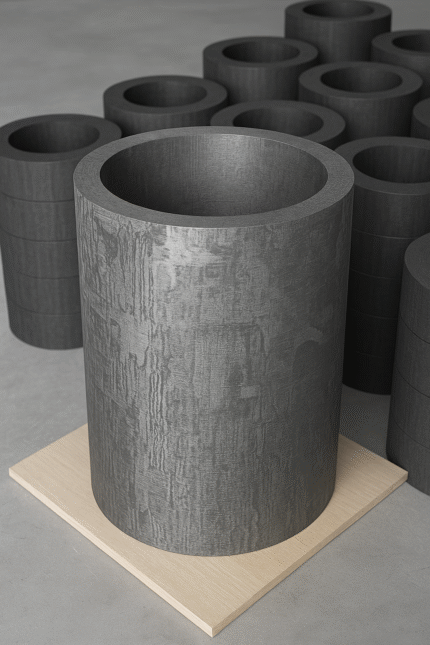

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

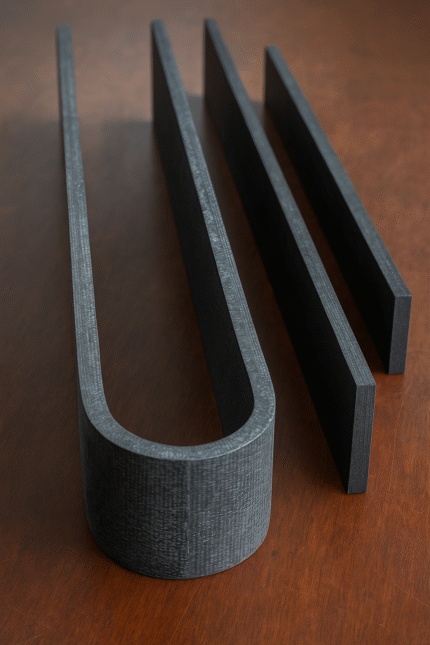

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

3D Carbon-Carbon Composite Materials

BZNCarbon offers high-density 3D carbon-carbon composites with exceptional strength and thermal stability. Ideal for aircraft brakes and structural parts exposed to extreme heat.

Category: C-C Composites

Tag: 3D Carbon-Carbon Composite Materials

Description

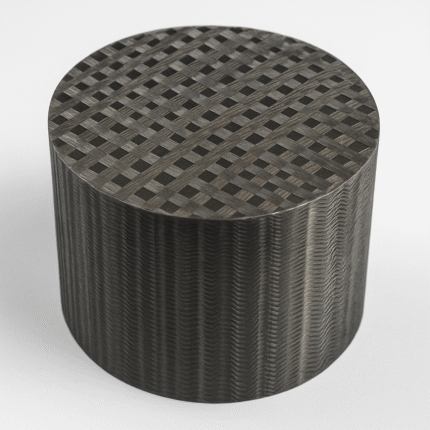

BZNCarbon’s 3D carbon-carbon composite (C/C) materials are advanced carbon fiber-reinforced carbon structures built to meet the needs of industries where strength, heat resistance, and longevity are essential. Unlike 2D composites that rely solely on fibers in two planar directions, 3D C/C composites incorporate reinforcement in all three axes (X, Y, Z), enabling them to withstand complex thermal and mechanical stresses.

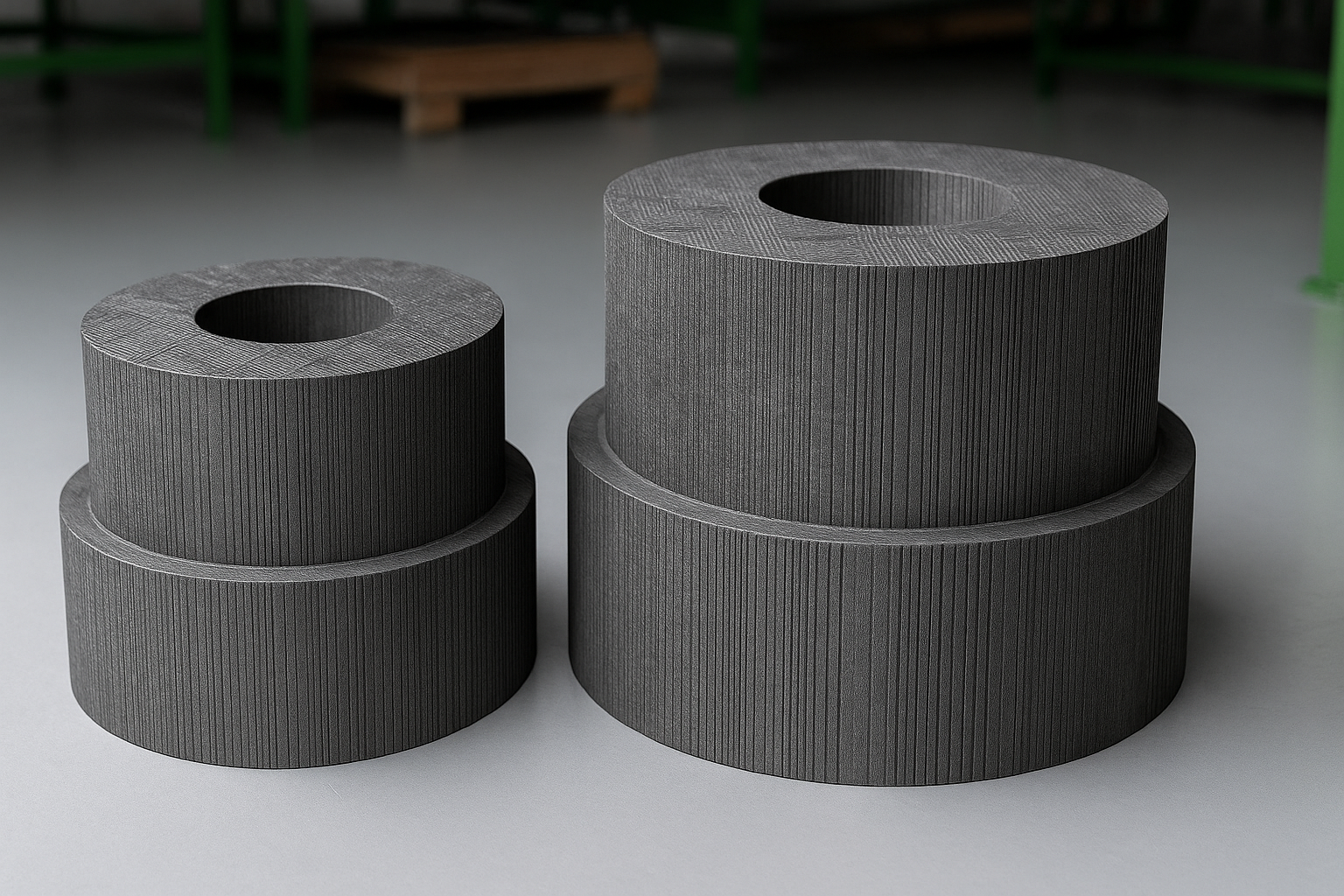

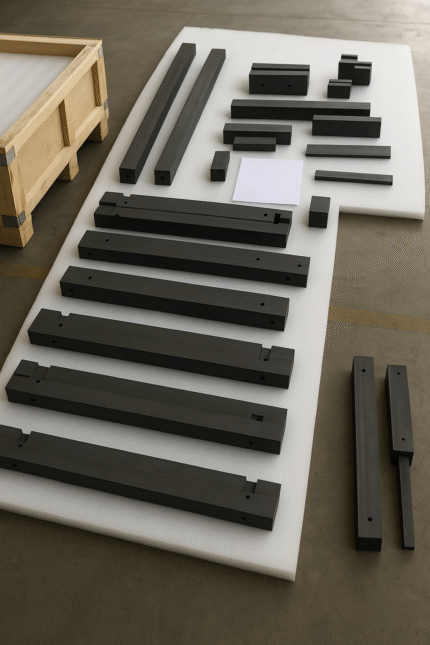

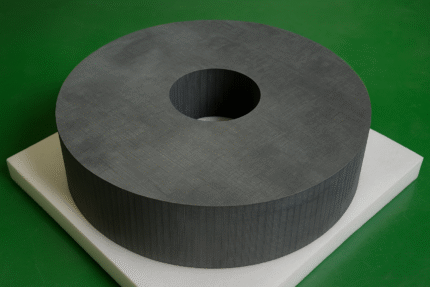

Available in standard and custom geometries—including disks, plates, and blocks—our 3D C/C composites can also be tailored using various weave architectures such as XYZ woven, axial-radial-hoop (also known as hoop 3D), or as per your proprietary design.

BZNCarbon is one of the few producers capable of achieving a minimum bulk density of 1.90 g/cm³, thanks to specialized HIP equipment, significantly enhancing the strength-to-weight performance.

What Is 3D Carbon-Carbon Composite?

3D C/C composite is a high-strength, high-temperature resistant material composed of carbon fibers embedded in a carbon matrix. The fiber orientation covers all three spatial axes, delivering isotropic mechanical reinforcement and increasing fracture toughness, dimensional stability, and thermal fatigue resistance.

This structural configuration allows for longer service life, improved heat distribution, and better resistance to internal cracking under thermal cycling or impact loads—particularly in aerospace braking systems and industrial high-heat environments.

Applications

Aircraft Braking Systems (civil and defense-grade)

Rocket Propulsion and Nozzle Components

High-Temperature Furnace Fixtures

Aerospace Insulation and Structural Linings

Heat Shields for Industrial or Space Systems

Thermal Protection Panels and Support Blocks

Aviation and Motorsport Disc Brakes

Key Technical Specifications

| Property | Direction | Requirement | Typical Result |

|---|---|---|---|

| Bulk Density | — | ≥ 1.85 g/cm³ | 1.868 g/cm³ |

| Fiber Configuration | — | 3D (X, Y, Z) | 3D (X, Y, Z) |

| Tensile Strength | X-Y / Z | ≥130 MPa / ≥70 MPa | 161 MPa / 76 MPa |

| Tensile Modulus | X-Y / Z | ≥50 GPa / ≥30 GPa | 59.1 GPa / 38 GPa |

| Flexural Strength | X-Y | ≥120 MPa | 142 MPa |

| Compressive Strength | X-Y / Z | ≥160 MPa / ≥220 MPa | 162 MPa / 274 MPa |

| Thermal Conductivity (900°C) | X-Y / Z | ≥40 / ≥20 W/m·K | 50 / 22 W/m·K |

| Thermal Expansion (at 1000°C) | X-Y / Z | 0.5–1 / 1–1.5 ×10⁻⁶/K | 0.55 / 1.16 ×10⁻⁶/K |

| Porosity | — | 3–5% | 4.3% |

| Specific Heat Capacity (RT–590°C) | X-Y / Z | Reported Value | 1.569×10³ / 1.620×10³ J/(kg·K) |

| X-Ray Inspection | — | No structural defects | Passed |

Custom test reports, X-ray validation, and shape adaptations available upon request.

Advantages

True 3D structure for multi-directional load-bearing capacity

High thermal conductivity and resistance to thermal shock

Ultra-low thermal expansion ensures shape integrity

Lightweight yet mechanically superior to traditional metals

Extremely low porosity and high purity

Stable under vacuum, inert gas, and oxidative conditions

Engineered for extended service life in critical systems