- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

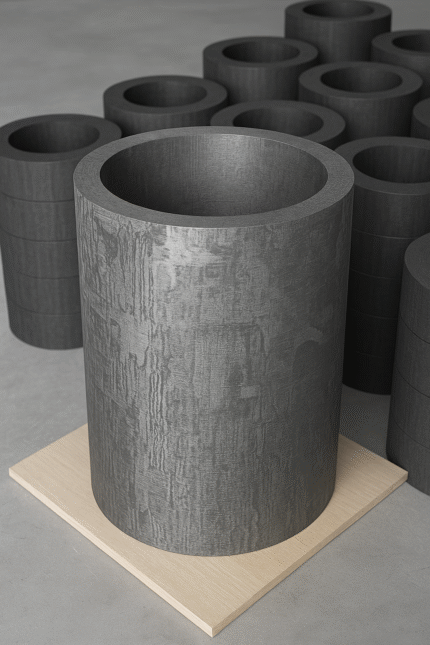

- Graphite Crucible

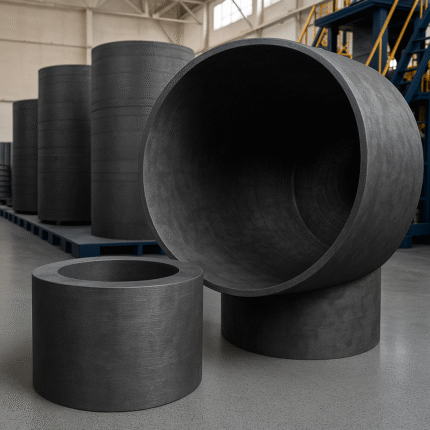

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

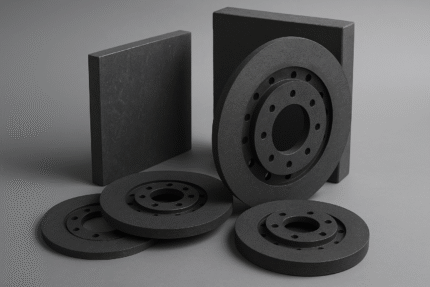

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

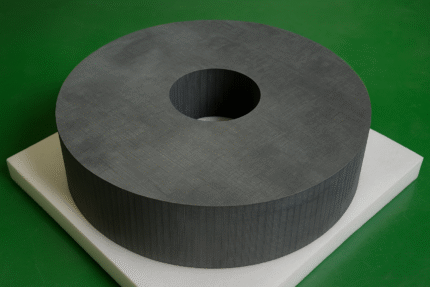

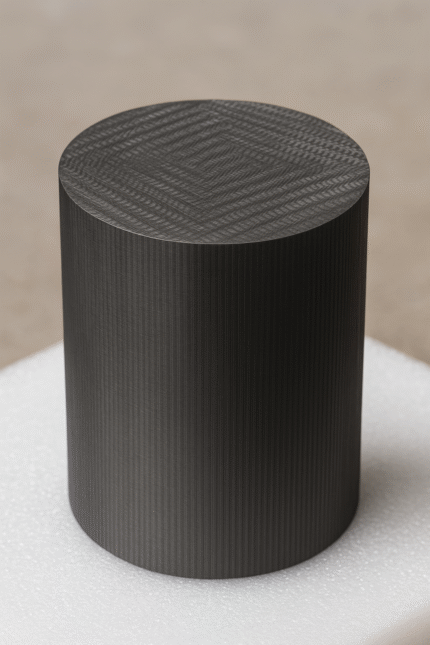

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

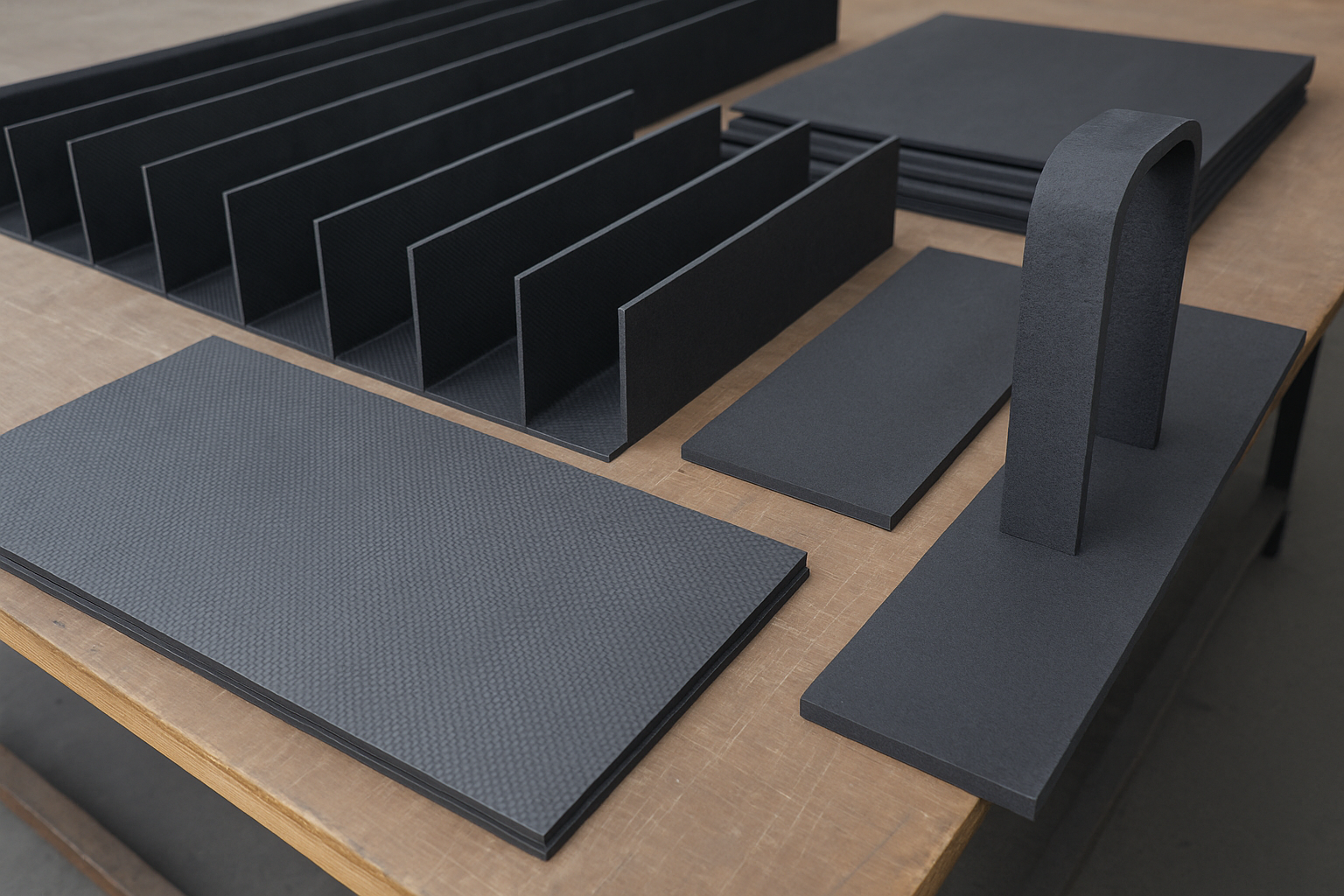

2D Carbon-Carbon Composite Sheets and Plates

BZNCarbon offers premium 2D carbon composite plates and sheets with outstanding thermal resistance, high strength, and lightweight structure for advanced industrial applications.

Category: C-C Composites

Tag: 2D Carbon Composite Sheets and Plates

Description

BZNCarbon 2D carbon composite sheets and plates are high-performance carbon fiber-reinforced carbon (C/C) materials designed for use in extreme thermal and mechanical conditions. Manufactured by layering carbon fiber fabrics in two orthogonal directions (x and y), these products offer excellent in-plane strength and high thermal stability.

The layered 2D architecture provides strong reinforcement along the surface plane, making these composites ideal for applications requiring low weight, excellent thermal conductivity, and resistance to heat shock and chemical corrosion.

Available in standard sheets, plates, and custom profiles such as U and L shapes, BZNCarbon’s C/C composites are tailored to meet the most demanding industrial needs.

Technical Specifications

| Property | Unit | Value |

|---|---|---|

| Bulk Density | g/cm³ | 1.4 – 1.6 |

| Carbon Content | % | ≥ 99.9 |

| Ash Content | ppm | ≤ 200 |

| Processing Temperature | °C | 2200 |

| Max Application Temperature | °C | Up to 3600 (in vacuum) |

| Size (max width × length) | mm | 1500 × 1000 |

| Thickness Range | mm | 1.6 – 20.0 |

| Tensile Strength | MPa | 40 – 60 |

| Tensile Modulus | GPa | 25 – 30 |

| Bending Strength | MPa | 80 – 110 |

| Compressive Strength | MPa | 90 – 120 |

| Thermal Conductivity | W/m·K | 30 – 50 |

Note: Other fiber types (e.g., 2.5D) and custom densities are available on request.

Key Advantages

Up to 5 times stronger than steel by weight

Operates reliably in vacuum or inert atmospheres above 2000°C

Withstands thermal cycling with minimal dimensional change

Low thermal expansion for shape and size stability

Excellent energy absorption due to high specific heat

Lightweight design—approximately 1/5 the weight of steel

Strong resistance to chemical corrosion and radiation exposure

Application Areas

Semiconductor and photovoltaic furnaces

High-temperature vacuum and inert gas heat treatment systems

Crystal growing equipment (e.g., silicon and sapphire growth)

Aerospace thermal protection and insulation

Glass molding and ceramic firing platforms

Nuclear and radiation-sensitive environments