- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

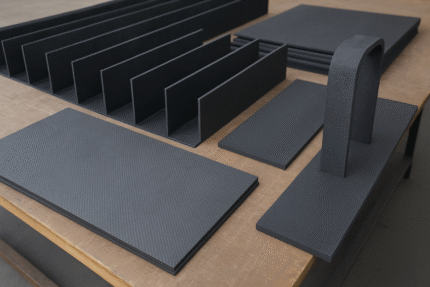

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

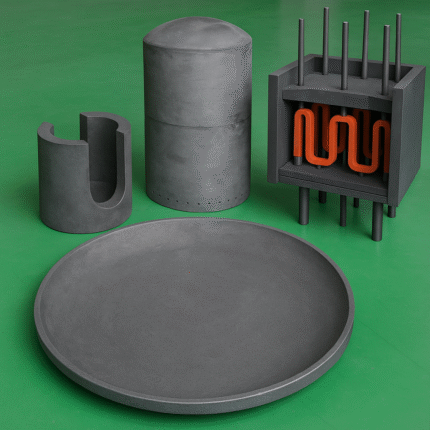

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

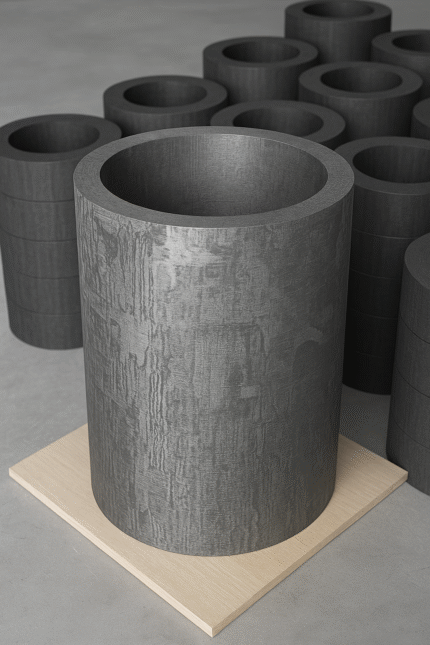

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

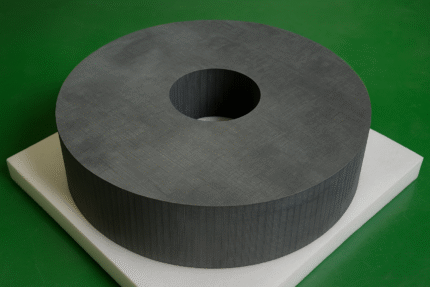

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

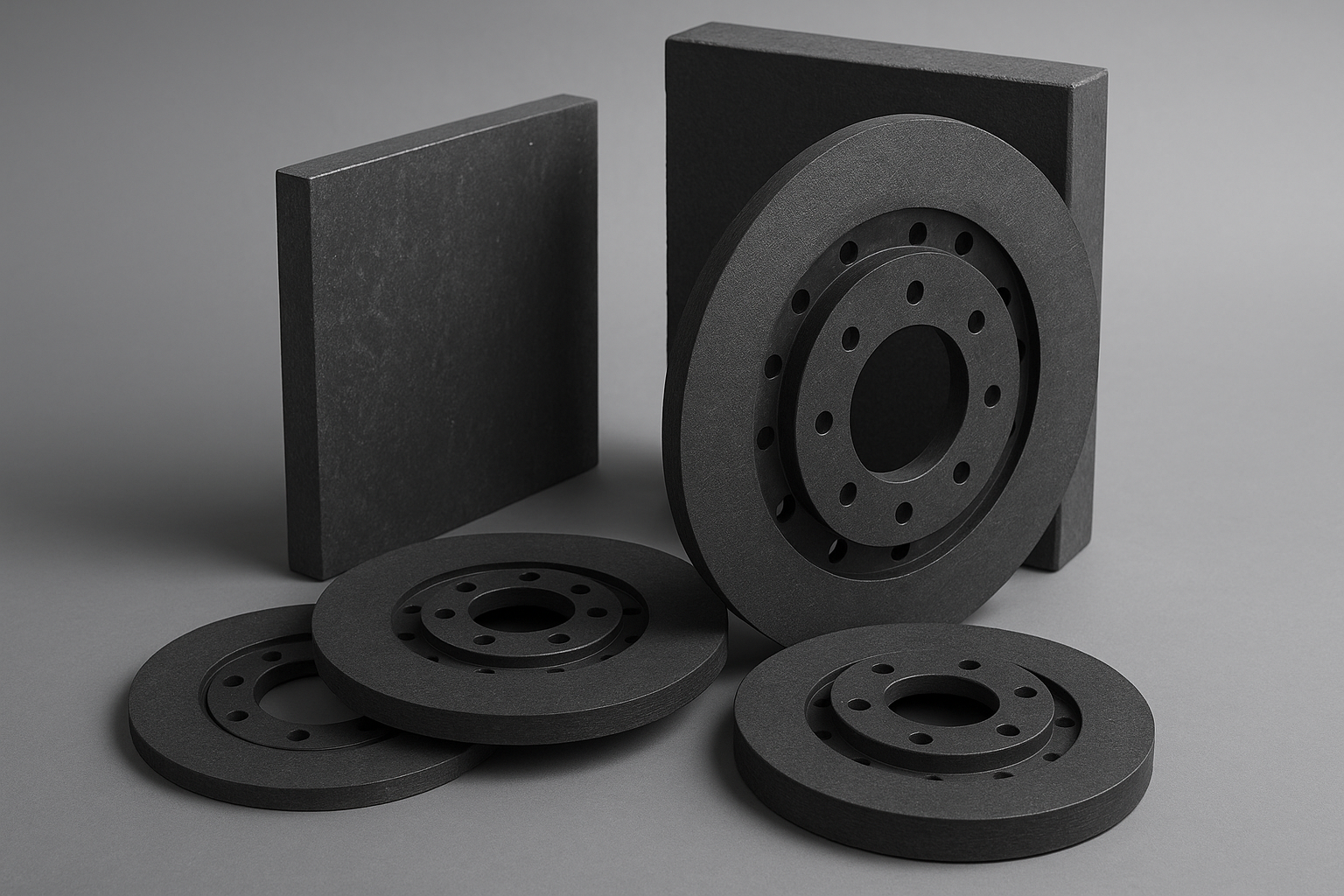

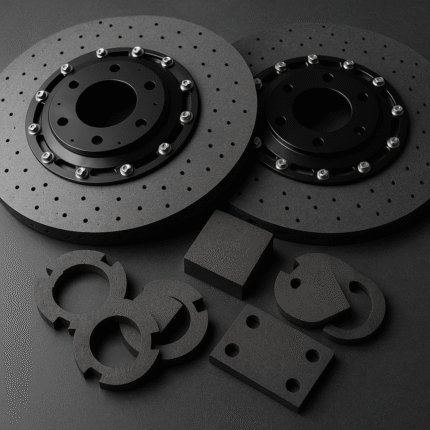

- Carbon Carbon Composite Racing Brake Discs and Pads

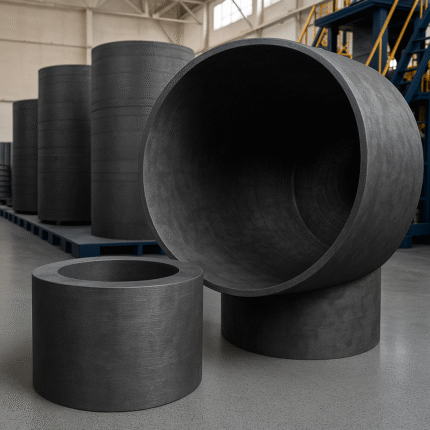

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

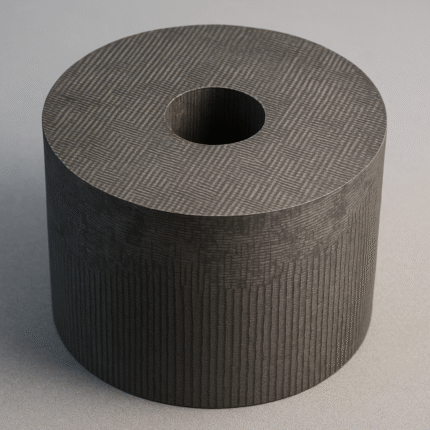

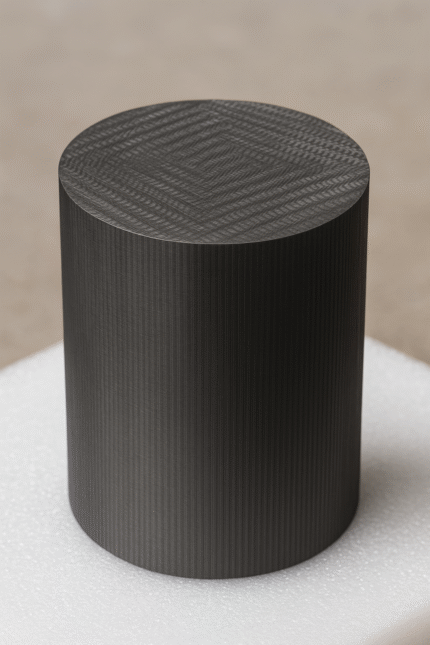

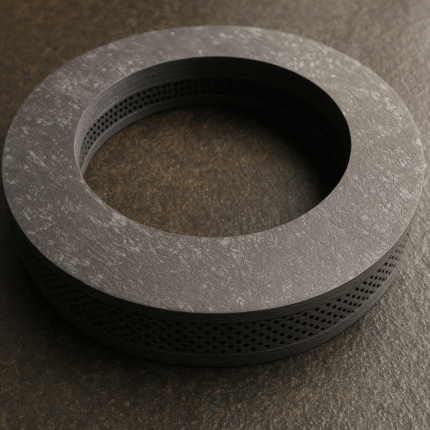

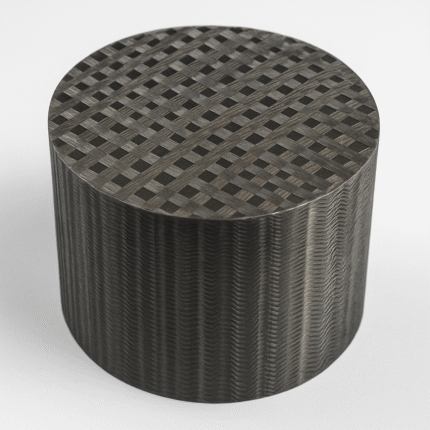

2.5D Carbon-Carbon Composite Materials

Discover BZNCarbon’s 2.5D carbon-carbon composite—designed for extreme temperature environments. Ideal for aircraft brakes and structural components with high strength, thermal stability, and wear resistance.

Category: C-C Composites

Tag: 2.5D Carbon-Carbon Composite Material

Description

BZNCarbon offers precision-engineered 2.5D carbon-carbon composite materials manufactured through multi-directional carbon fiber reinforcement and high-temperature processing. Compared to standard 2D composites, the 2.5D structure includes interlaminar fiber reinforcement, delivering enhanced durability in dynamic and high-friction environments.

This material is ideal for aerospace-grade components, particularly aircraft brake discs, where high mechanical strength, low weight, and thermal stability are essential. Each product is processed at temperatures exceeding 2000°C and tested to ensure reliable performance under demanding conditions.

What Is 2.5D C/C Composite?

2.5D carbon-carbon composites are an evolution of 2D structures, built from stacked carbon fiber fabric layers with added reinforcement in the through-thickness (Z) direction. This limited Z-direction reinforcement provides improved shear strength without significantly increasing weight or cost, making 2.5D composites a strategic choice for friction materials and thermal shielding in aerospace, defense, and industrial sectors.

Key Features

High-temperature resistance up to 2000°C and beyond

Stable mechanical properties in vacuum and inert atmospheres

Excellent wear performance and extended service life

Lightweight: approx. 1/5 the density of steel

Minimal thermal expansion for dimensional stability

High thermal conductivity and shock resistance

Excellent friction behavior: stable dynamic and static coefficients

Resistant to acids, alkalis, and thermal fatigue

Application Areas

Aircraft brake discs (civil and military)

High-temperature structural components

Heat shields and insulation fixtures

Rocket and aerospace propulsion elements

Automotive racing brake systems

Friction and wear-resistant industrial parts

Technical Specifications

| Property | Unit | Value |

|---|---|---|

| Bulk Density | g/cm³ | ≥ 1.78 |

| Carbon Content | % | ≥ 99.99 |

| Bending Strength | MPa | 140 |

| Compressive Strength | MPa | ≥ 180 |

| Interlaminar Shear Strength | MPa | > 15 |

| Thermal Conductivity | W/m·K | 20 – 80 |

| Dynamic Friction Coefficient | — | 0.24 – 0.42 |

| Static Friction Coefficient (20.6 MPa) | — | ≥ 0.16 |

| Linear Wear (Inertial Platform) | µm/time/face | ≤ 1.5 |

| Processing Temperature | °C | > 2000 |

| Ash Content | ppm | ≤ 100 |

| Metallic Ash Content | ppm | ≤ 50 |

X-ray and custom non-destructive testing available upon request.

Custom shapes, densities, and composite structures can be manufactured based on your design files.

Additional Information

Depending on the application, this material is also referred to as:

CFC, Carbon Composite, C/C, Carbon Fiber Composite, Carbon Reinforced Carbon, Carbon-Carbon

While all these names point to the same base technology, the 2.5D architecture offers a balance between cost efficiency and mechanical reinforcement, making it a preferred option in applications where 3D composites may be too heavy or expensive.