- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

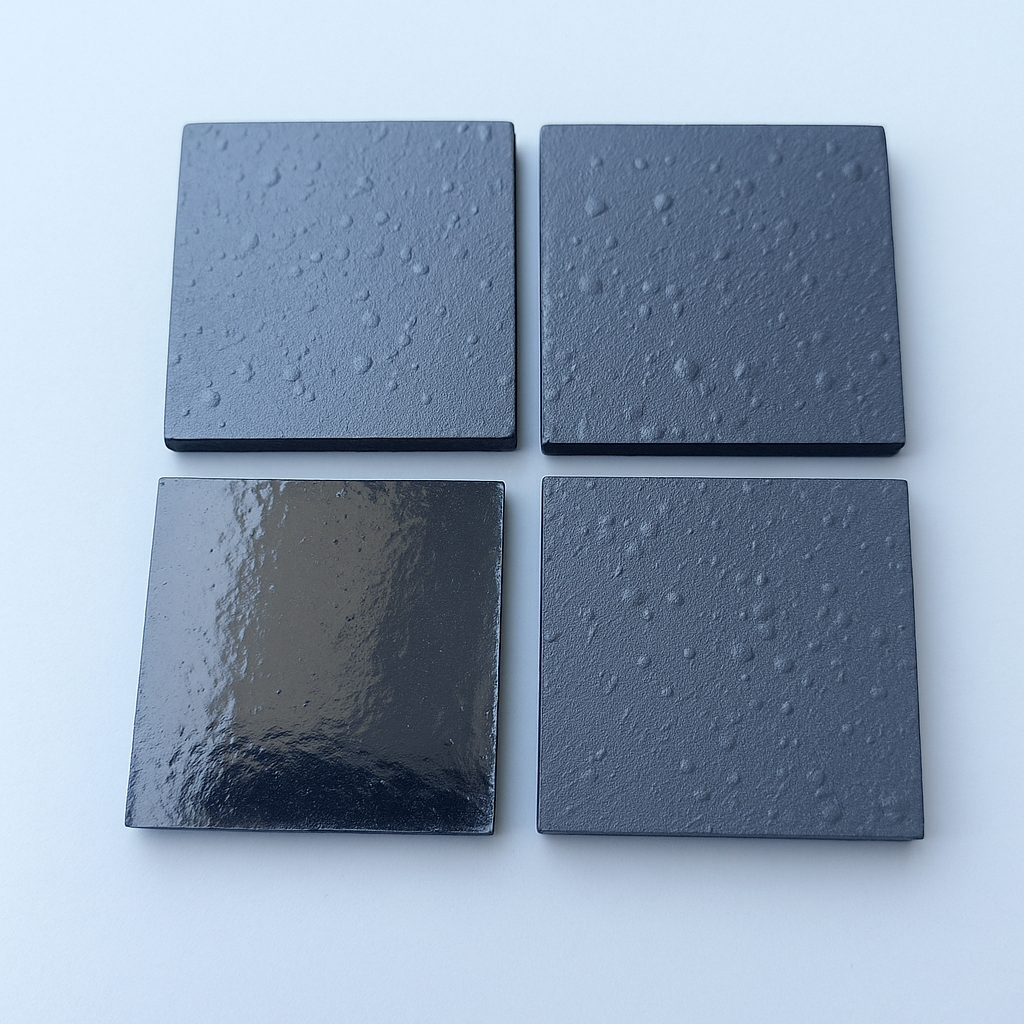

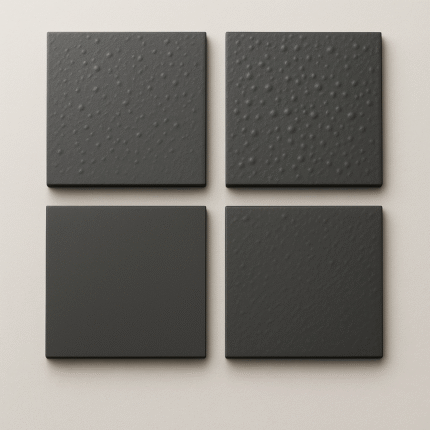

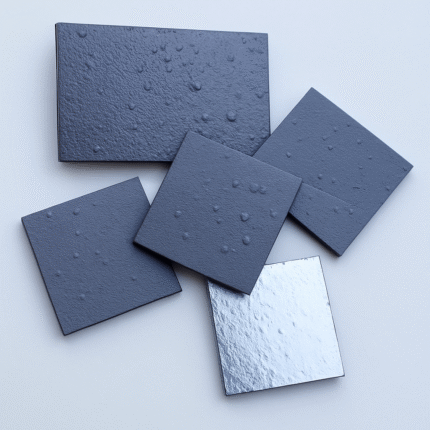

Pyrolytic Graphite Plates

BZNCarbon supplies high-purity pyrolytic graphite plates with stable and reliable quality. We offer both PG grade and HOPG grade pyrolytic graphite products in the form of plates and boards.

Category: Pyrolytic Graphite

Tag: Pyrolytic Graphite Plates

Description

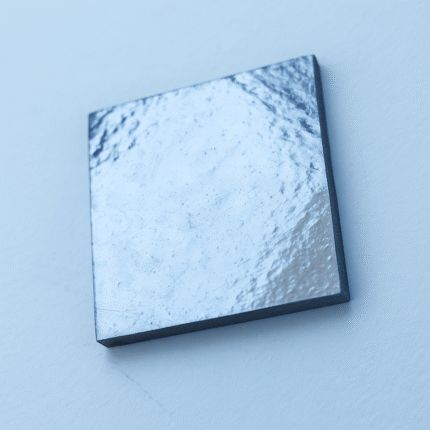

Pyrolytic graphite is an advanced carbon material produced through chemical vapor deposition of hydrocarbon gases at 1800–2000 °C under controlled pressure. This process results in highly oriented crystalline layers, giving the material excellent anisotropic properties such as superior thermal and electrical conductivity in the AB plane, while offering high mechanical strength and extremely low impurity levels (as low as 0.0002%).

Pyrolytic graphite maintains structural integrity under high temperatures, up to 1800 °C in a vacuum of 10 mmHg, making it ideal for extreme conditions.

Typical Applications

Semiconductor heat spreaders

Nuclear reactor shielding

Aerospace insulation and radiation barriers

Advanced thermal management in electronics

X-ray and neutron monochromators

Magnetic levitation and sensor substrates

Standard Properties of Pyrolytic Graphite Plates

| Property | Value / Range | Direction |

|---|---|---|

| Density | 2.18–2.20 g/cm³ | – |

| Compressive Strength | 83.6 MPa | AB |

| Tensile Strength | 75 MPa | AB |

| Ash Content | 0.02–0.005% | – |

| Thermal Conductivity | 300–400 W/m·K | AB |

| Thermal Conductivity | 3.5–5 W/m·K | C |

| Coefficient of Thermal Expansion (CTE) | 3.2×10⁻⁶/°C | AB |

| Coefficient of Thermal Expansion (CTE) | 17–26×10⁻⁶/°C | C |

| Specific Resistance | 2×10⁻⁴ Ω·cm | AB |

| Specific Resistance | 0.6 Ω·cm | C |

| Interlayer Spacing d(002) | ≤ 3.42 Å | – |

| Air Impermeability | He transmissivity < 10⁻¹⁰ cm² | – |

Available Sizes

90 mm × 5 mm (dia)

90 mm × 90 mm × 5 mm

90 mm × 200 mm × 5 mm

Max Width: 180 mm

Max Length: 800 mm

Max Thickness: 10 mm