- Graphites

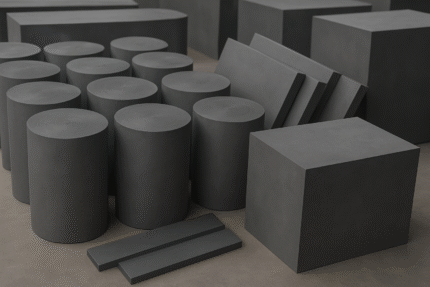

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

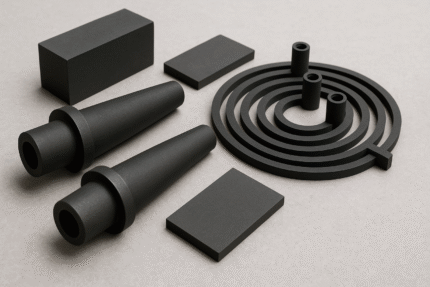

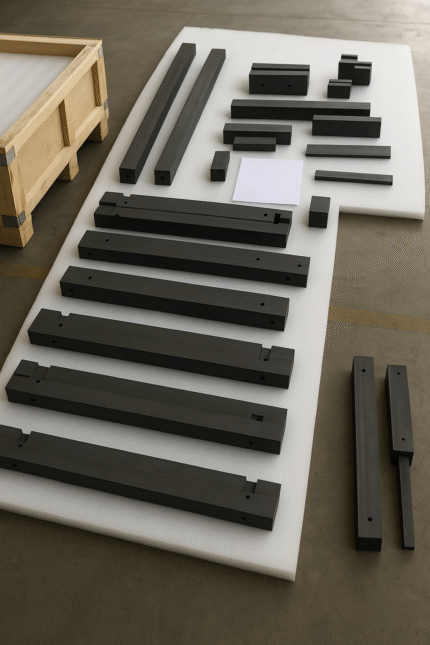

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

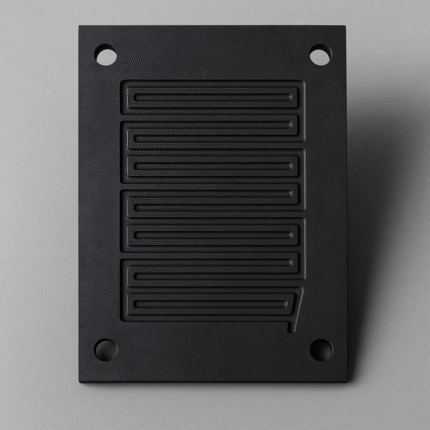

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

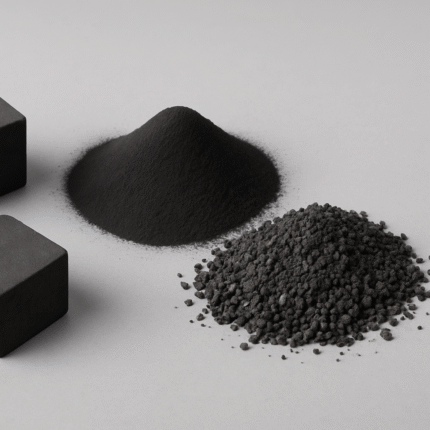

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

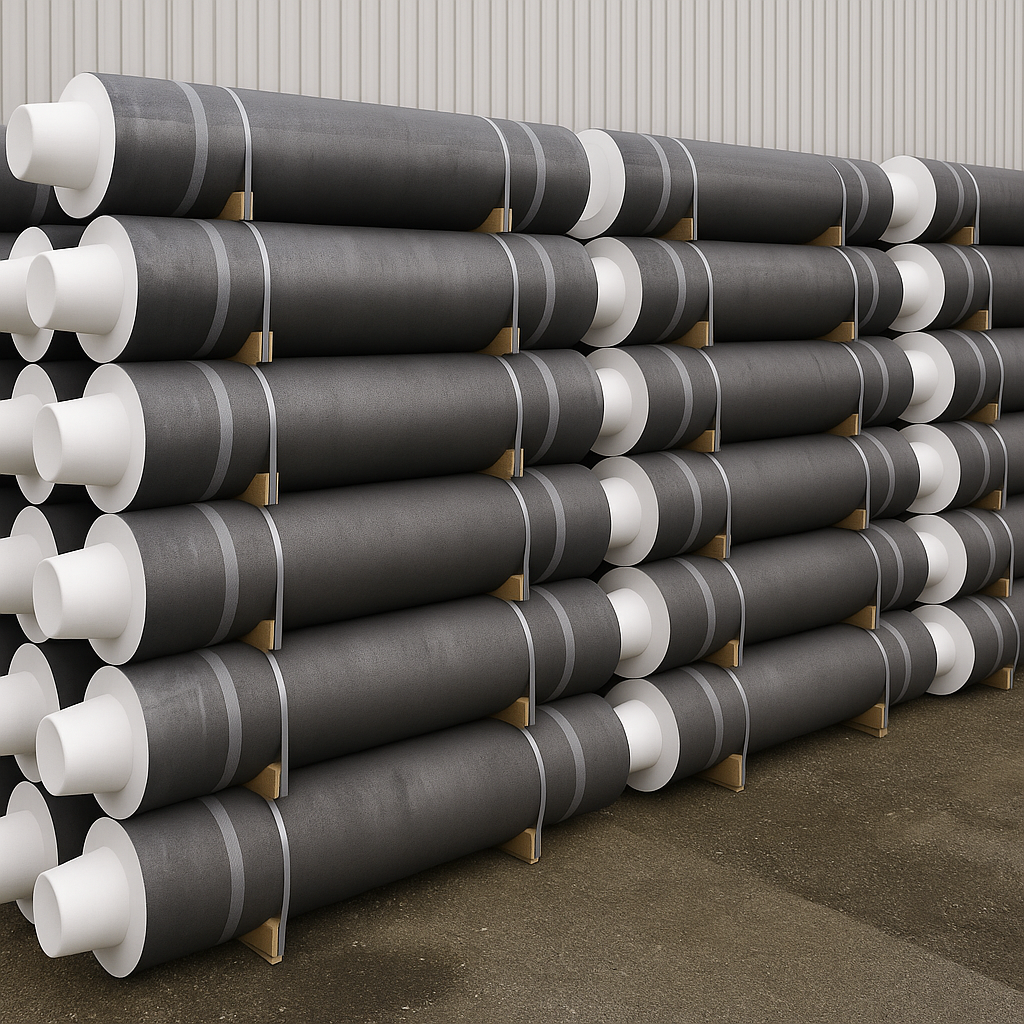

Graphite Electrode

BZNCarbon supplies premium quality Graphite Electrodes, engineered to deliver consistent performance in Electric Arc Furnaces (EAF) and Ladle Furnaces (LF) used for steelmaking and non-ferrous metal processing. These electrodes act as critical conductors of electric current at low voltage and high amperage to generate the thermal energy required for melting and alloying operations.

Category: Graphites

Tag: Graphite Electrode

Description

Why Graphite?

Graphite remains the most reliable and efficient material for electrode production due to its:

High electrical and thermal conductivity

Excellent mechanical strength

Outstanding resistance to thermal shock

Easy machinability

Controlled thermal expansion characteristics

Our Offering

BZNCarbon manufactures graphite electrodes ranging from 200 mm (8″) to 750 mm (30″) in diameter across multiple power grades:

UHP (Ultra High Power)

SHP (Super High Power)

HP (High Power)

RP (Regular Power)

All grades are compatible with AC and DC furnaces.

The UHP grade, designed for maximum efficiency, is produced using needle coke – a high-quality raw material essential for achieving optimal performance in high-demand melting processes.

Applications

Steel production (EAF route)

Ferroalloy production

Ladle refining

Smelting non-ferrous metals such as copper, nickel, and zinc

Recycling operations in mini-mills

Key Product Advantages

Long service life

High current load capacity

Superior oxidation and erosion resistance

Reduced electrode consumption rate

Available in custom lengths and diameters per client specification

Related products

Select options

This product has multiple variants. The options may be chosen on the product page

Calcined Petroleum Coke

150,00 €

Select options

This product has multiple variants. The options may be chosen on the product page

Expanded Graphite Powder – High Conductivity Grade BZ-20

250,00 €

Select options

This product has multiple variants. The options may be chosen on the product page