- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

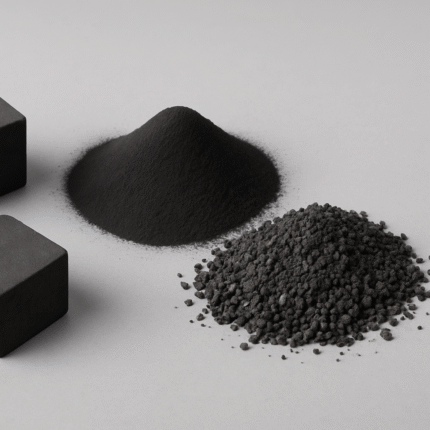

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

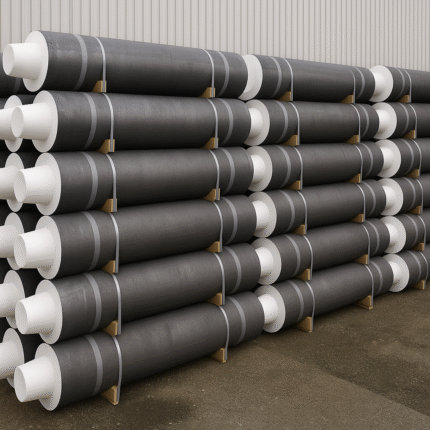

- Graphite Pipe

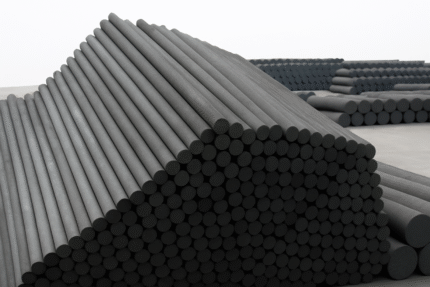

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

CNC Machining Graphite Parts

At BZNCarbon, we specialize in precision graphite machining, offering CNC-machined graphite parts and graphite molds with stable and reliable quality. Tolerances and surface treatments can be customized according to your specific requirements.

Category: Graphites

Tags: CNC Machining Graphite Parts, Graphite Parts

Description

Product Overview

Our CNC graphite components and molds are widely used across industries such as automotive, aerospace, semiconductors, chemicals, metallurgy, nuclear, and electronics.

We produce:

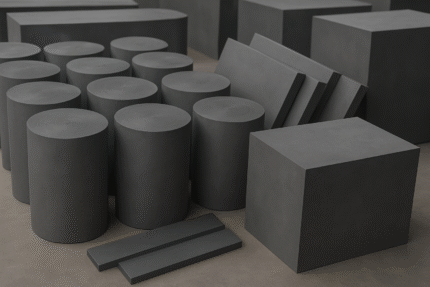

Graphite rods

Graphite plates

Graphite blocks

Graphite crucibles

Graphite pipes and tubes

Graphite vanes

Graphite brushes

Custom CNC-machined graphite components

Machining Capabilities

Precision tolerances as per drawings

Custom surface treatments

Capability to machine all major graphite grades (isostatic, extruded, molded, vibration)

Complex geometries and fine-detail parts

Excellent dimensional accuracy and consistency

Advantages of Graphite Molds

Excellent thermal and electrical conductivity

Exceptional thermal shock resistance with low thermal expansion

Chemically inert and corrosion resistant

Strength increases at high temperatures (above 800°C)

Natural lubricity and low wear rate

Easy to machine into complex, high-precision shapes

Main Applications of Graphite Molds

Continuous and semi-continuous casting molds for non-ferrous metals like aluminum and copper

Pressure casting molds used in the automotive industry

Centrifugal casting molds for bronze bushings and larger sleeves

Hot pressing molds for carbide sintering

Glass molding molds for tubes, funnels, and complex shapes

Sintering molds for diamond tools and semiconductor parts

EDM electrodes replacing copper in spark erosion processes

Why Graphite for EDM Electrodes?

2–3× faster discharge rate than copper

High-temperature resistance with minimal deformation

Lightweight (1/5 the density of copper)

Low electrode wear due to protective carbon layer

No post-processing required for burr removal

Easier to grind and polish

More cost-effective than copper, especially at scale

Graphite Mold Technology & Industry Role

Graphite molds are core equipment in modern industrial production. With growing demands in automotive, electronics, and precision industries, graphite is becoming the preferred mold material for:

High-speed, high-efficiency mold production

Superior performance under high temperature and load

Long service life and stable processing quality

BZNCarbon contributes to this development with locally produced, high-quality graphite mold solutions engineered for industrial excellence.

Available Graphite Grades:

Isostatic graphite

Molded graphite

Extruded graphite

Vibration graphite

Mechanical graphite

Carbon brush grade

Related products

Select options

This product has multiple variants. The options may be chosen on the product page

Calcined Petroleum Coke

150,00 €

Select options

This product has multiple variants. The options may be chosen on the product page

Expanded Graphite Powder – High Conductivity Grade BZ-20

250,00 €

Select options

This product has multiple variants. The options may be chosen on the product page