- Graphites

- Isostatic Graphite

- Molded Graphite

- Extruded Graphite

- Vibration Graphite

- Mechanical Carbon Graphite

- Graphite Box for Anode Material

- CNC Machining Graphite Parts

- CNC Machining Graphite Parts

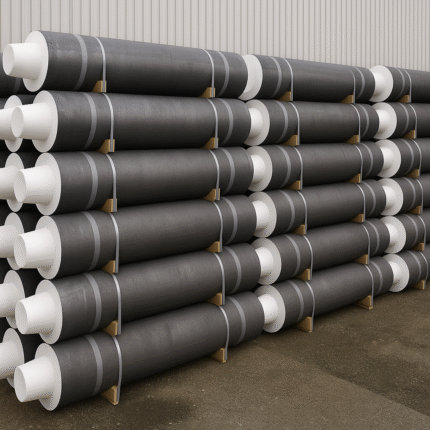

- Graphite Electrode

- Graphite Bipolar Plate

- Carbon Brush/Electric Brush

- High-Purity Graphite Powder for Lithium-Ion Battery Applications

- Graphite Hot Zone for PV

- Calcined Petroleum Coke

- Graphite Products for Glass Industry

- Graphite Crucible

- Graphite Pipe

- Graphite Rod/Block/Plate

- Expanded Graphite Powder – High Conductivity Grade BZ-20

- C-C Composites

- 2D

- 2D Carbon-Carbon Composite Sheets and Plates

- 2.5D Carbon-Carbon Composite Materials

- 3D Carbon-Carbon Composite Materials

- 4D / 5D Carbon-Carbon Composite Materials

- High-Density Carbon-Carbon Composite Materials

- Carbon-Carbon Composite Aircraft Brake Discs

- Carbon-Carbon Composite Heaters & Heating Elements

- Carbon-Carbon Composite Insulation Barrels & Blankets

- Carbon-Carbon Composite Moulds

- Carbon-Carbon Composite Screws & Studs

- Carbon Carbon Composite Crucible

- Carbon Carbon Composite U & L Profiles

- Carbon Carbon Composite Blocks

- Carbon Carbon Composite Racing Brake Discs and Pads

- Carbon Carbon Composite Rods, Tubes, and Pipes

- Carbon Composite Bolts and Nuts

- Carbon Ceramic Composite Materials and Precision Parts

- Pyrolytic Graphite

- Carbon Felt / Graphite Felt

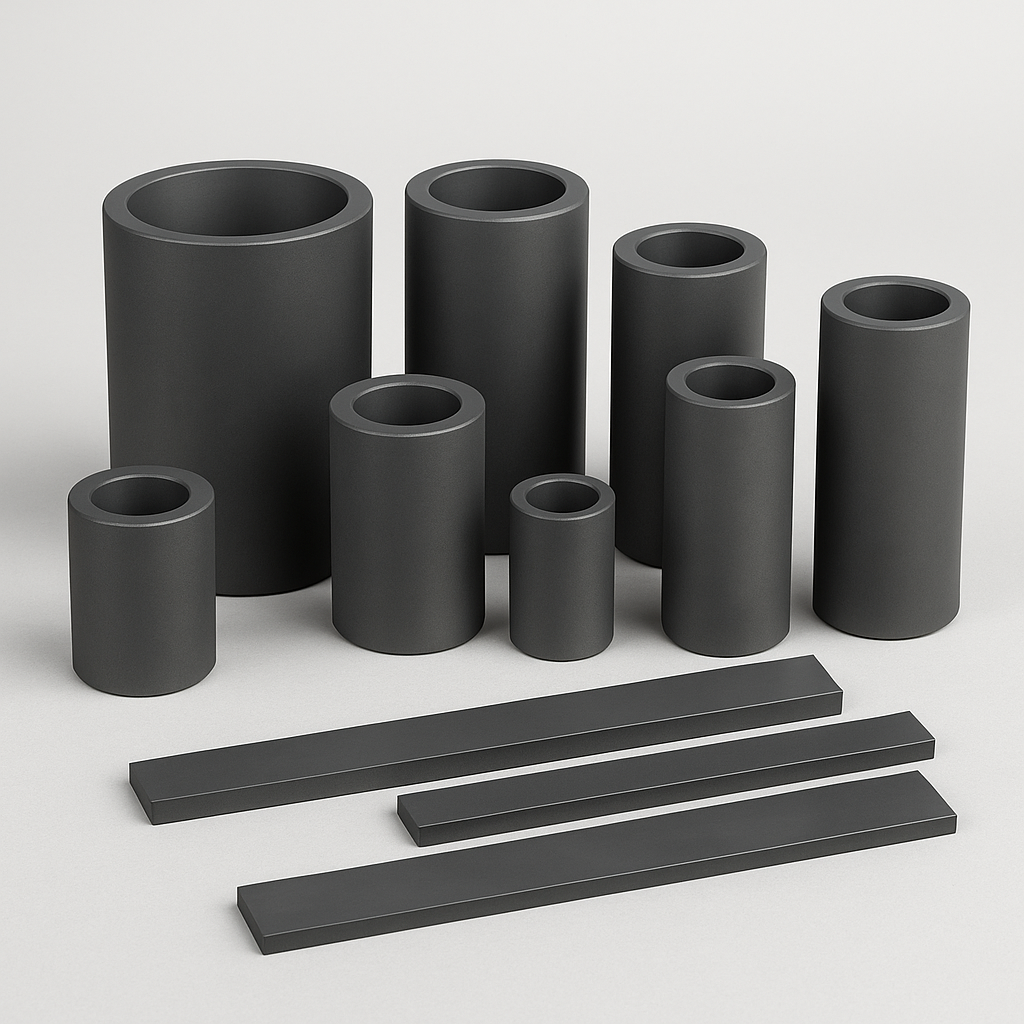

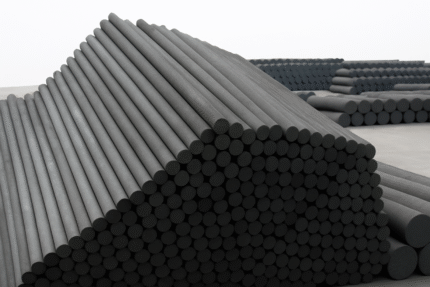

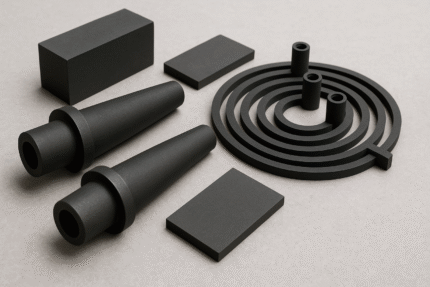

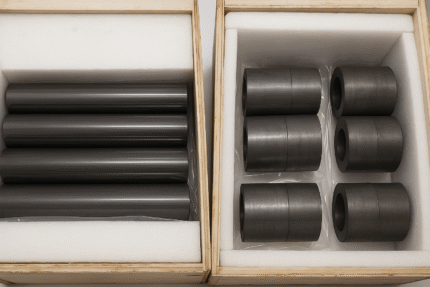

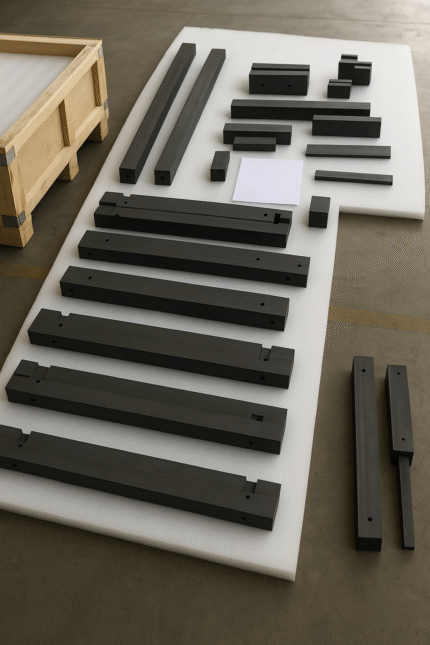

Mechanical Carbon Graphite

At BZNCarbon, we produce and supply impregnated mechanical carbon graphite materials with stable quality and custom configurations for demanding industrial applications. These composites are formulated by impregnating graphite with various agents such as resin, copper, antimony, and silver, resulting in enhanced performance in conductivity, wear resistance, and corrosion resistance.

Category: Graphites

Tag: Mechanical Carbon Graphite

Description

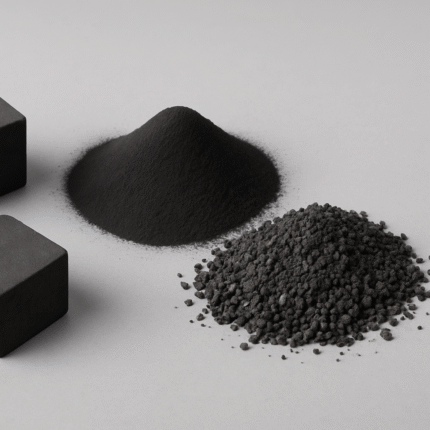

What is Impregnated Graphite?

Impregnated graphite is a composite material formed by filling pores of base graphite with impregnating substances (resin or metals), then solidifying through high-temperature treatment. This process enhances strength, sealing ability, conductivity, and chemical durability.

Main Types of Mechanical Carbon Graphite

Resin Impregnated Graphite

High density (up to 2.0–2.5 g/cm³)

Excellent corrosion resistance

Ideal for chemical environments, seals, and bearings

Max temperature resistance: ~200°C

Grades: M106H, M120H, M106K, M120K, M254K

Copper Impregnated Graphite

Combines the mechanical strength of copper and thermal conductivity of graphite

Used in rolling equipment, metallurgy, turbines, molding machines

Grades: M106P, M120P, M254P

Antimony Impregnated Graphite

Superior lubrication and wear resistance under extreme conditions

Operating range: −253°C to +500°C

Works under high RPM (20,000), high pressure (10 MPa)

Grades: M106D, M120D, M254D

Silver and Other Metal Impregnated Graphite

Enhanced conductivity and durability

Used in specialized high-tech fields

Key Features

Self-lubricating with or without oil

Excellent resistance to high temperatures, corrosion, and pressure

High electrical conductivity and dimensional stability

Custom machinability for seals, rings, vanes, bushings, and sleeves

Lightweight and adaptable in harsh environments

Typical Applications

Chemical and Petrochemical:

Heat exchangers, condensers, pump seals, reactor tanks

Withstands acids, alkalis, corrosive vapors

Metallurgy and Energy:

Electrolytic cells, continuous casting molds

Lubricant-free rotating equipment parts

Arcing components and electrodes

Industrial Equipment:

Compressors, injection molding machines, turbines

Conductive components for electronics and telecom

Emerging Fields:

New energy (fuel cells), aerospace, and defense sectors

High-temperature nuclear components and shielding

Related products

Select options

This product has multiple variants. The options may be chosen on the product page